BORA Glass Filled Nylon Track Clamp Set for WTX or NGX Saw Clamp Edges (2-Piece)

$24.94

Provide an essential and ultimate addition to your construction application with this affordable BORA Track Clamp Pair for WTX or NGX Saw Clamp Edges.

In stock

Description

The Track Clamp allows you to see and use your WTX or NGX Clamp Edge saw guide from a whole new angle. It used to be that you could only cut 90° angle with the BORA Clamp Edge. Now you can make any angle you want, thanks to the Track Clamp. Cutting a 35° angle. Go for it. A 67° angle. Easy. Even a 83.75° angle. If you really want to, the Track Clamps make it possible.

- Makes any angle fast, easy and accurate

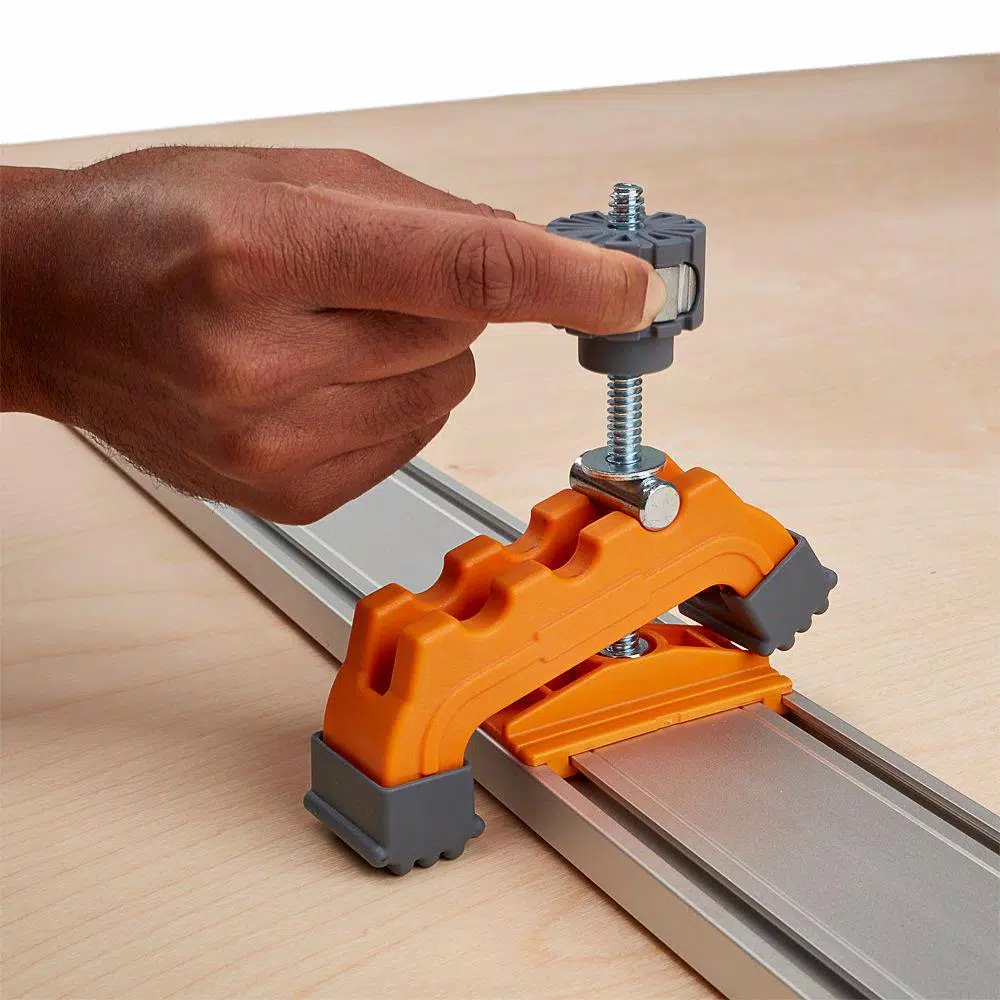

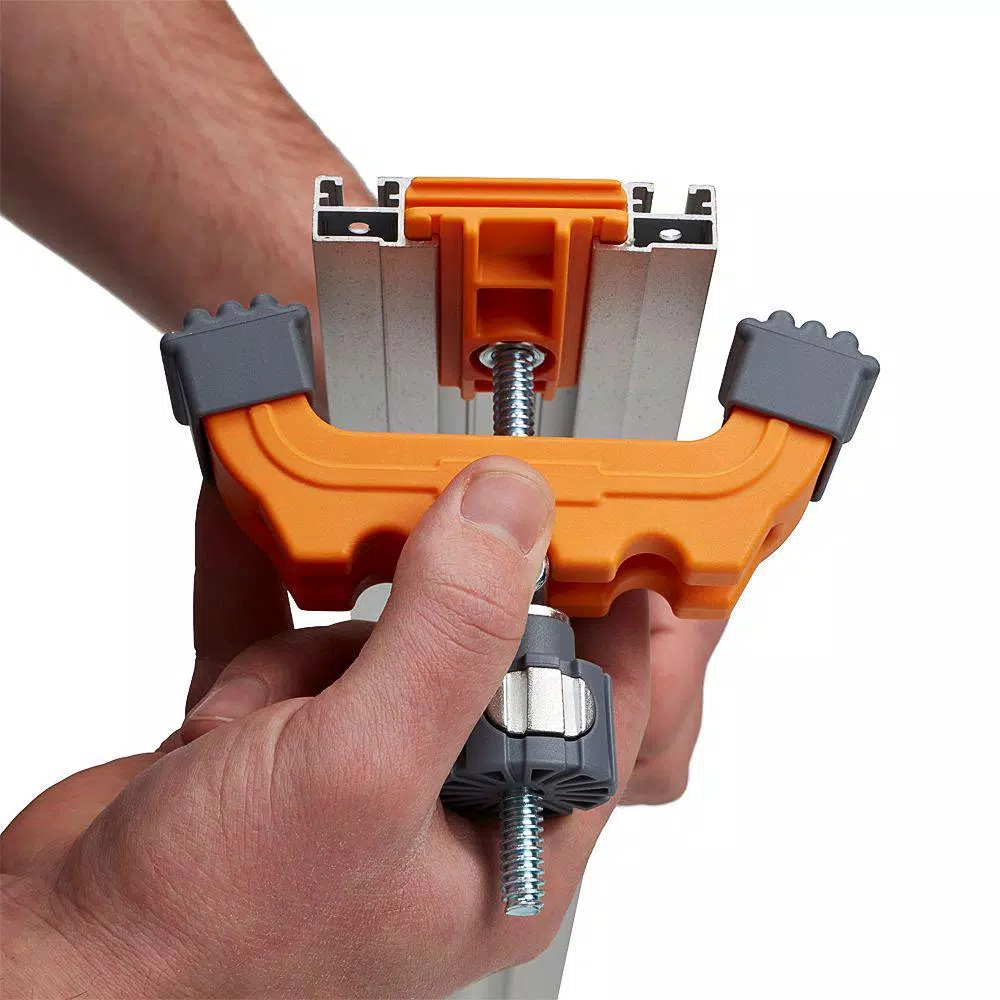

- Easy to adjust and use with fast-acting lock nut

- Helps quickly process panel material

- Slides into both top and bottom of track for multi-purpose functionality

- Works with WTX and NGX clamp edge saw guides

Additional information

| Weight | 0.5 lbs |

|---|---|

| Dimensions | 6.25 × 5.50 × 1.75 in |

| Clamp Type | Toggle |

| Color Family | Orange |

| Hand Tool Type | Clamp |

| Individual/Set | Set |

| Model | 542011 |

| Number of Pieces | 2 |

| Tool Set Type | Clamp/ Vise Sets |

| Tools Product Type | Hand Tool |

Reviews (86)

86 reviews for BORA Glass Filled Nylon Track Clamp Set for WTX or NGX Saw Clamp Edges (2-Piece)

Only logged in customers who have purchased this product may leave a review.

Related products

Hand Tool Sets

Klein Tools 5-Piece Assorted Screwdriver Set- Cushion Grip Handles

Model# 85075Hand Tool Sets

Model# 63518Hand Tool Sets

Model# 70575Hand Tool Sets

Model# 89032Hand Tool Sets

Model# 35102Hand Tool Sets

Model# 436-0Hand Tool Sets

Model# 437-0Hand Tool Sets

Model# 22

Gracie Padberg (verified owner) –

I have wanted a track saw to breakdown plywood for a long time, but I could not justify the cost for a tool that I would use only a few times per year. The Bora NGX 5-Piece Clamp Edge Deluxe Set is well designed, extra sturdy and easy to use. The Bora NGX Set is less than one-third the cost and functions just as well as a track saw; therefore I think it is the perfect alternative for the DIYer who cannot afford a track saw. The BORA NGX clamping system is super strong and will not slip. I was especially pleased with the track clamps that came with the set, they allow the clamps to be used to make cuts at angles other than 90 degrees. Joining the two 50 inch straight edges together with the track clamps allow for angle cuts even on sheets of plywood. A phillips head screwdriver is required to connect the two straight edges together, but even though this may be a hassle, it serves to insure that the straight edge is indeed straight.I was impressed that the set even came with 2 Rolls of 55-inch self-adhesive non-chip strips used for reducing top edge tear-out. I was disappointed with the instructions that came with the set, I found them to be almost useless. I also had to look through several tool bags to find a #3 allen wrench which is required to move the brackets that hold the skill saw on the saw plate—it seems that a #3 allen wrench could be included in the set. I did find a wonderful video on YouTube from WorkshopAddict that does an excellent job of showing me all of the features of the BORA NGX set.I would definitely recommend the BORA NGX 5-Piece Clamp Edge Deluxe Set for anyone who already has a skill saw and is looking for a low cost alternative to a track saw.

Brandi Kessler (verified owner) –

I have used this quite often. The only problem that I had was with the base when I attached my saw I was trying to cut the edge of my countertop which was 1 1/2″. My 7 1/2″ blade wouldn’t cut deep enough to get the whole edge.

Elisha Kovacek (verified owner) –

I found this guide to be very solid as I did not see any measurable deflection when using it and it worked great as a guide. However, not a great track saw substitute. Using either the Saw Plate or just the guide, I found the cuts to be true. I also found that it helped when using the Saw Plate to use a dry lubricant (I used PTFE) on the guide as this allows the saw move much easier on the guide. The guide itself is easy to set up and when locked down it doesn’t move. Using the Saw Plate ensures that your cuts will be true. (I have been known to drift away from a guide.) I think the clamps that allow the guide to be used at an angle across a piece of plywood were very clever and worked great.However, I found the lack of instructions for setting it us to use like a track saw to be lacking to say the least. The instructions were just pictures without any written explanations of any of the steps. Consequently, it took me quite a while to get the saw(s) set up to see how they worked. In addition, it requires a metric allen wrench to set up a saw on the Saw Plate and this wasn’t included so I had to file down another allen wrench to fit. I set put the ‘non chip strip’ on the guide and tried the saw with 24-tooth blade and had minimal tear-out. However, when I switch to the saw with the 60-tooth blade I did have tear-out. Not sure why. I joined the two sections of the guide together to see how that worked and found the joint was not exact, and I had to file the bottom of the lead edge of the Saw Plate so it would not hang up on the joint.I recommend this product an the basis that you will get straight true cuts using the guide particularly when using the Saw Plate. I would have rated it higher if it in fact eliminated tear-out and the instructions were easier to follow. I also found that the nuts that are held in position when tightening the guides on the Saw Plate can rotate as they are not a snug fit in the slots they sit in.

Saul Johns (verified owner) –

So my Dad had a guide for his circular saw which was two pieces. It was a pain to setup & get straight. I ordered this guide because it was one piece & can be setup with one hand as I demonstrate in the video below. When cutting thick plywood, using one of these guides is way easier & more accurate than trying to rip the material on a table saw or using a circular saw freehand. Mine came with a sled, which can be used in conjunction with the guide to make the cutting easier & more accurate.

Karianne Lockman (verified owner) –

This is a strong, easy to operate clamp with a versatile saw guide attachment (Model 544050, Made in China). The clamp is 50” in length, long enough to use on a 4′ x 8′ piece of plywood to cross-cut it. The clamp adjusts by sliding the clamp end, but the mechanism must be FULLY disengaged or it will not slide. As with most clamps, the edge will not automatically be square to the clamping surface so use a square to align the clamp. The clamping force is STRONG, and takes a bit of muscle to lock/unlock the clamp. It’s enough to actually bend 1/4” plywood (see photo) so it will hold tightly during use. The clamp has two parallel slots on it that are perfect for holding 1/4” bolts, including toilet bolts, meaning the clamp can be used with homemade jigs. There is a nice hanging hole at the top of the clamp. This clamp is much better than either of the other two 50” clamps I own and will get a lot of use.I normally cut plywood by just sliding my circular saw against the edge of the clamp, and usually don’t drift from the clamp. The Edge Saw Guide virtually eliminates the chance of drift by riding BOTH sides of the clamp. The base adjusts for most saws (right or left-handed) and locks onto the saw with three clamps. Adjustment is a one-time task, requiring a 3mm hex (allen) wrench, which was not supplied. Unfortunately for me, there was no way to adjust the clamping bolts to engage on a flat spot on my saw base, which has a grid pattern, so the grip was tenuous at best. The guide comes with a strip of plastic to be installed as a “non-chip” edge, preventing the wood from splintering along the cut (similar to a zero-clearance throat plate on a table saw). I chose not to install mine, as it limits the clamps use as an edge guide for other saws and/or router. The clamp and guide work perfectly without it, but the cut itself might not be as clean on the upper surface.For my money I would buy the clamp and skip the Edge Saw Guide, especially since it doesn’t fit my particular circular saw as well as it might fit others. It’s a good quality accessory, but doesn’t add enough value for me.

Avery Klocko (verified owner) –

Thought I was getting Justin and guide clampdown style for for power saw ended up getting a bonus edge guide which my circular saw fits into which I thought was rather nice used it a couple times so far seems to work rather well there’s a chip strip that goes with the text chance to stop the wood from chipping back if you’re doing doors so you don’t chip the edges makes it look clean would recommend this for anybody replacing or buying a new Edgcote clampdown style

Rossie Lesch (verified owner) –

This clamp will work well for long cuts as it will reach across a 48 inch width and It comes with an extension for a full 8 foot use. The clamp easily slides in the track and you can adjust pressure by careful placement. The clamps are only 3/4 inch thick so it works well with most stock.It also comes with a sled to mount your circular saw on. It is designed to hold most by simple adjustments. All of this can be a challenge to figure as the instructions are broken to simple drawings and no written text. There are also some clamps included which are designed for making long angle cuts.

Kaela Beatty (verified owner) –

I have used a few different clamp edge guide before so I am familiar with this type of product. This one is the best one that I have used by far. For me, it is the clamping action that makes it stand out. This may seem simple but other manufacturers have not gotten this perfect in my opinion. The clamp holds very tight without squeezing the material too much. Others will either slip because they are not tight enough or they will be so tight that either the edge guide or the material is bowed. Bora gets it perfect!

Jon Bernhard (verified owner) –

Saw plate gets hung up on track guide joint screw heads.

Anastasia Cremin (verified owner) –

It’s a bit difficult to set up. A lot of folks recommend using it with a dedicated saw and keeping that saw attached to the plate, which I think would help. But it makes excellent straight cuts, and sets up much faster than my old straight edge.

Archibald Hammes (verified owner) –

This Bora 50-inch Clamp Edge Saw Guide is a welcome addition to my woodworking tools. I bought a similar small clamp edge type guide many years ago at a woodworking show in Phoenix, but this Bora clamp edge is far superior to that one. First of all, the Bora NGX is 50 inches long, so it can clamp all the way across a 4 x 8 sheet of plywood. (My old clamp edge guide is only 26 inches long, so it has limited use as a saw guide.) The Bora clamp edge aluminum rail is slightly more than 1/2 inch thick, so it is very sturdy.The main rail of the Bora NGX clamp edge is made of extruded aluminum and the clamping mechanism and end stop are made of some kind of sturdy molded thermo-plastic. When released the clamping end slides easily in the double track slots of the aluminum rail. When you get it in position against the edge of your plywood, a simple flick of the T-handle locks the clamp edge in place ready to guide your saw. Bora sells a separate NGX saw plate that can ride on top of the clamp edge rail or you can just allow for your saw’s blade offset and let the saw’s edge be guided by the clamp edge rail.My only complaint (which is a pet peave of mine) is that Bora slapped a UPC sticker on the clamp edge rail where it meets the cardboard packaging (see photo) that was very hard to remove. It took me 15 minutes of soaking the UPC label remnants with WD40 and scrubbing with paper towels to remove the label adhesive without damaging the aluminum rail’s finish. Sterlite, who makes plastic storage boxes, manages to make labels that stick to the product but are very easy to remove without leaving adhesive residue, so why can’t other manufacturer’s follow their lead?

Zita Beahan (verified owner) –

Wish I had this a few years ago!

Kevin Halvorson (verified owner) –

Perfect for cutting ACM panel on my drafting table

Korey Goodwin (verified owner) –

This is a must have for small shops. It’s a great straight edge. Now, I have had it slip on me a couple of times. I now clamp both ends as an added safety measure.

Annabel Stoltenberg (verified owner) –

Bought this specifically to cut up plywood safely. The Bora NGX clamp definitely does this. For the price, this is a great little unit. It cuts spot on every time. Like any tool, you have to understand how it works and be aware of a few things to ensure it performs properly. On the NGX clamp, here are some things to keep in mind. Note, these are not in any way flaws. 1.) It does take about 15 minutes to connect your circular saw and dial the settings in to ensure adequate space between the cutting blade and the material. I have a DeWalt DWE575 and dialed it so the clamp is exactly 9/16 from my cut line. 15 minutes is not a lot of time, its easy. Do a few practice cuts. I recommend getting it dialed in to an exact measurement and there are markings on the slide piece to help you do this. Also recommend, clamp the top first, then do the 2 side clamps.2.) In the times I tried to use the right angle guide, it has not performed well. I bought the Premier set mainly because it was the only item available as the other parts (bought separately) were out of stock. In other words, I wouldn’t buy the Premier for this one part.3.) When cutting, be sure to put pressure on the right side of the guide. This ensures there is less blade deflection as you cut. 4.) Some folks complain the clamp down slide gets stuck. The trick is this… The gray handle and the orange edge has to come together in order to slide it. Simple. If it’s not sliding… just push them toward each other, you’ll feel a little click and it slides great.5.) Using the extension piece takes practice to ensure it’s spot on straight once the 4 screws are screwed in tightly. I find that screwing them in a little then pushing both slide components together and then screwing in the screws fully works best. Always check to make sure this is straight, common sense.6.) Some folks have mentioned the plastic construction of the base plate and clamp down. I’m not too worried about this. It’s pretty decent grade plastic. You’ll definitely get a few years out of this tool before anything breaks. If it does, just replace the part. Every tool wears.7.) The instructions… ha, this is one area that could use improvement. However, if you know how to use a circular saw and have actually changed out blades, the setup is pretty self-explainatory. Plus there’s plenty of videos out there.To close, even when I do get a table saw, I will still use the Bora NGX to cut full size plywood down to a more managable size. It is the safest way to do this and watching videos of people doing this on a table saw is pretty funny when you look at their eyes cause they know are uncomfortable.

Oran Reynolds (verified owner) –

BORA NGX 5-Piece Clamp Edge Deluxe Set – Almost everyone who has used a tracksaw appreciates its accuracy and clean cutting results, but their price tags are high and maybe prohibitive for the occasional user and Do-It-Yourself-er. This Bora set is a good option to avoid paying $500 and more for a good tracksaw. It does require a decent circular saw and a good blade that isn’t included, but most woodworkers already have one. Once the saw is mounted on the sled and the track clamped to the material it is easy to get straight clean cross-cuts and rips. I tested it by cross-cutting a piece of ½” plywood. The results were a smooth straight cut with almost no splintering.The track comes in two sections that can be combined to cut 8’ long boards and full-length plywood. I did wipe some silicone on the track to make the sled slide smoother but other than that it works great.The one issue I have is with the assembly instructions. They are all illustrations of steps to install and set up your saw and assemble the track etc. The problem is there isn’t any text to explain what you are doing or how to do it. Just pictures. Going through the process was some trial and error. For instance, it shows mounting the saw to the sled, but doesn’t tell you that the sled needs to be on the track for blade clearance. I included a photo that illustrates adjustments for the saw that I assume is for blade clearance. I found it hard to see why the two lines on the left are wrong and the lines on the right are correct.

Jaylen Jaskolski (verified owner) –

Great for cutting sheet goods. The only downside is that it’s not easy to connect & disconnect to the extension.

Kristofer Rodriguez (verified owner) –

I set this up today to test it out, First I removed my Craftsman circular saw from another brand track saw base. Then I installed it on the Bora base using the instructions that came with the set. First problem was the instructions are not the best but still able to figure things out. I set the tack across my table saw and placed the base on the track then the saw on the base. This let me adjust it to the track so the saw is not skewed on the base. After installing the saw on the base I installed the tear out strips. They were very easy to install and fit perfect to the track. Then I placed the base with saw on the track again and checked that the blade would ride along the edge of the tear out strip all the way down both pieces of track.. Its now ready to use. I took a piece of 3/4″ red oak plywood that was 76″ long and 24 1/2″ wide and cut 1/2″ off the whole langht so I had 76″ X 24″. I don’t have alot of room to work so I would rip my sheets of ply out side using my truck and a saw horse. but this time I just layed it across my table saw and clamped it down and cut it. The two piece of track connected together and the bora track layed down and clamped with the slide clamp only it was solid as a rock it was not moving. I placed the base and saw on the track and made a perfect cut and my work piece was nice and clean no tear out at all. Now with it 24″ wide I needed 2 pieces 28″ long so I took off the extension track and just use the 1 piece to cut across the width to cut off 28″. Now the left over piece I took and cut off another 28″ langth with my table saw then I compared the 2 pieces and they both were perfect and match up they both were square to each other. I find the base rides on the track very smooth and it does not skew any when you stop and start again. There is no slop in the base when riding along the track. I did not use the 2 track clamps at this time but thay are great I checked them out and thay adjust great they fit the track with no problems and I know I will use them alot in the future. Now with all that said the only thing I can see a problem with is the nuts on the bottom of the base. when I went to adjust the lock down track on the base the nuts turned in the grove. This should be a long nut made with flat stock so it can’t turn in the grove not a hex nut that will ware the plastic if its tighten and loosen to maney times. For me its ok I am leaving the saw set up. Even with the one flaw above this is easer and better than the other brand I have been using that I had to go buy clamps to hold it down to keep it from walking on cuts. Its also harder to set up for long cuts so The Bora clamp edge deluxe set is a Plus plus for me. Now all I need is a Bora Centipede so I dont have to use my truck as a table.

Camille Rowe (verified owner) –

NEVER A CROOKED CUT – THIS IS A WOODWORKERS MUST HAVE TOOL – THIS “BORA PORTAMATE” 50 INCH SAW GUIDE SYSTEM IS GREAT – THE CLAMP EDGE GUIDE HAS FIXED END CLAMP HEAD SO YOU JUST PLACE, ADJUST & CLAMP FROM ONE SIDE -YOU CAN RIP & CROSSCUT PLYWOOD WITH YOU CIRCULAR SAW – STRAIGHT EVERY TIME – BUILD WITH RIGID ALUMINUM FOR STRENGTH & ACCURACY – USED WITH THE “SAW PLATE” FOR PERFECT CUTS.

Kayley Herzog (verified owner) –

It makes cutting perfect straight lines with a circular saw easy. This will cut across the 48” side of plywood or any sheet good. You can also add another 50” section and rip the full length of a sheet of plywood. Cheaper than a track saw.