BORA Glass Filled Nylon Track Clamp Set for WTX or NGX Saw Clamp Edges (2-Piece)

$24.94

Provide an essential and ultimate addition to your construction application with this affordable BORA Track Clamp Pair for WTX or NGX Saw Clamp Edges.

In stock

Description

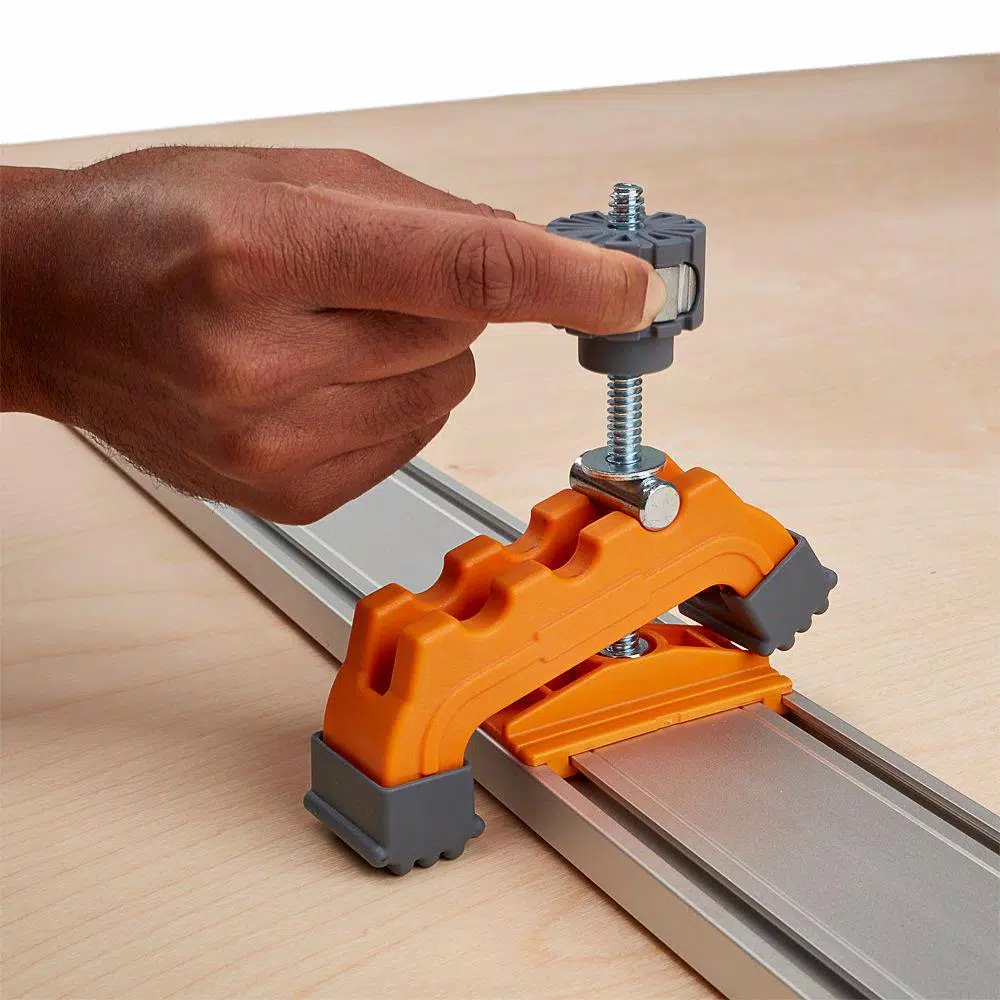

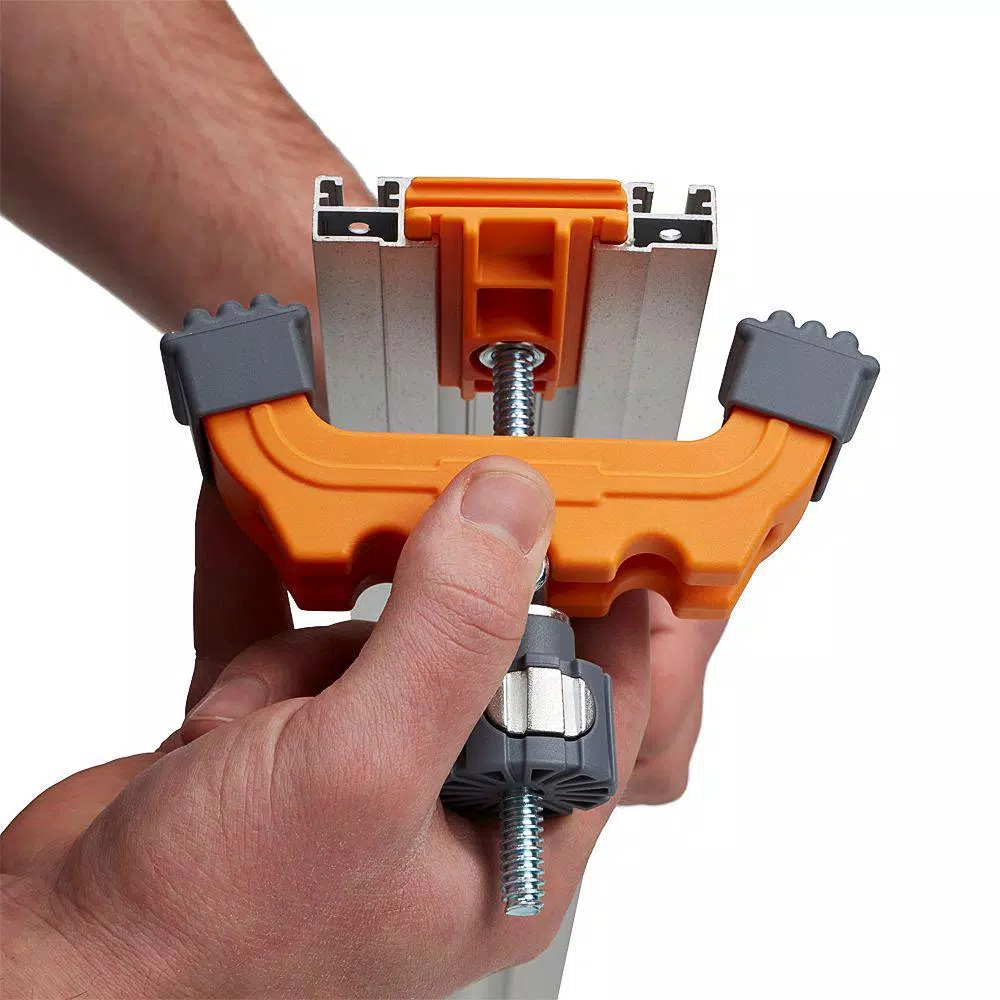

The Track Clamp allows you to see and use your WTX or NGX Clamp Edge saw guide from a whole new angle. It used to be that you could only cut 90° angle with the BORA Clamp Edge. Now you can make any angle you want, thanks to the Track Clamp. Cutting a 35° angle. Go for it. A 67° angle. Easy. Even a 83.75° angle. If you really want to, the Track Clamps make it possible.

- Makes any angle fast, easy and accurate

- Easy to adjust and use with fast-acting lock nut

- Helps quickly process panel material

- Slides into both top and bottom of track for multi-purpose functionality

- Works with WTX and NGX clamp edge saw guides

Additional information

| Weight | 0.5 lbs |

|---|---|

| Dimensions | 6.25 × 5.50 × 1.75 in |

| Clamp Type | Toggle |

| Color Family | Orange |

| Hand Tool Type | Clamp |

| Individual/Set | Set |

| Model | 542011 |

| Number of Pieces | 2 |

| Tool Set Type | Clamp/ Vise Sets |

| Tools Product Type | Hand Tool |

Reviews (86)

86 reviews for BORA Glass Filled Nylon Track Clamp Set for WTX or NGX Saw Clamp Edges (2-Piece)

Only logged in customers who have purchased this product may leave a review.

Related products

Hand Tool Sets

Model# 35202Hand Tool Sets

Model# 89082Hand Tool Sets

Model# 90402Hand Tool Sets

Model# 33Hand Tool Sets

Model# 89062Hand Tool Sets

Model# 436-0Hand Tool Sets

Model# 89052Hand Tool Sets

Klein Tools 3-Piece Fully Reversible Ratcheting Offset Box Wrench Set

Model# 68244

Ressie Rosenbaum (verified owner) –

I like the Bora NGX clamp edge but was disappointed that it did not come with a tape to attach to the edge for the saw guide zero clearance cuts. Was very surprised to find that the plastic tape costs over $20.00. I bought this so that I wouldn’t have to separate my existing 50 inch clamp and extension. I only paid $150 for the 50inch clamp, 50inch extension, saw guide, 2-55″ tapes, and 2 clamps. Since I paid $59.94 for the 50″ clamp and will have to pay $20 for the tape guess I should have just bought 2 $149 packages and had a spare tape and saw guide.

Noemi Nitzsche (verified owner) –

This clamp edge was very easy to use.

Ibrahim O’Connell (verified owner) –

Making precise cuts on sheet goods has always been a problem. As a hobbyist who makes a lot of furniture and cabinetry, I usually do precision cuts on the table saw. But making precision cuts on sheet goods has always been a problem. In the past I would calculate the offset and clamp a board to the plywood and hope that the board was straight and square. My norm was to cut oversize and then do the precision on the table saw, but that was not always possible. A track saw would do a much better job, but I could not justify the expense. When I got the BORA 50” NGX Clamp Edge I found I no longer had to rely on the accuracy of whatever board I happened to find. This clamp adjusts quickly and is automatically square with the surface. It holds tightly and cures most of the difficulty I had. By adding the NGX Pro Saw Plate, it allows me to use my circular saw like a track saw. Now I can rip through sheet goods precisely without calculating the offset and with the non-chip strip attached to the clamp, tear out is greatly reduced. The circular saw attaches quickly and securely to the Saw Plate with 3 locking hold downs. Once I found the proper Allen wrench, setup was easy and I was ready to saw. (Hint – it is 3mm.) Very happy with this combination and it will definitely save me a lot of time and material.

Dax Zemlak (verified owner) –

Worked as described.

Kathlyn Ward (verified owner) –

Excellent guide and easy to use. When the two parts are assembled, they formed a straight edge that was verified with a level. Highly recommended.

Eunice Green (verified owner) –

Perfect for cutting ACM panel on my drafting table

Gudrun Crona (verified owner) –

Have you ever had to rip a piece of material and tried to do it with just a steady hand? It’s really hard to get a straight accurate cut. The Bora five piece clamp set with straight edge gives you the ability to get a straight clean cut. You can do four or eight foot material and if the clamp set is difficult to figure out there is a web site available with instructions on the proper use of this handy tool

Dallin Koelpin (verified owner) –

I deserve a hard kick in the pants – for not getting one of these tools years ago. Like many DIYer, I have struggled with using a piece of extruded aluminum or angle iron and a pair of clamps to cut straight lines (hopefully) in large sheets of material. The setup was time consuming and the cut wasn’t always straight. This tool virtually eliminates both of those problems. Very easy to use – with excellent clamping force – and sturdy enough to always get straight cuts. They also have a saw adapter (purchased separately) that holds the saw in a tray which slides along on top of the saw guide – eliminates the possibility of the saw drifting off track. This tool is a must have for any volume of 4X8′ cutting.

Keaton Jones (verified owner) –

This NGX Saw Plate can be great but it does not fit my Milwaukee M18 circular saw and the directions are complicated. The plate will hold the vast majority of circular saws though and glides across the BORA NGX Saw Edge systems. The problem with my M18 circular saw is that its bottom plate is not a rectangle, the back inside end does not have a corner for the clamp to attach nor can I ensure that my saw is perfectly square on the ruler marks of the NGX plate (see pictures). The directions are complicated. First, I put the no-chip strip in the wrong spot. The directions say to put it on the edge of the NGX Edge saw guide but didn’t specify underneath the Edge. I tried to remove the strip but the adhesive came off too and it was a mess. Second, its fairly easy in theory to mount a saw on the plate but the directions make it difficult. I found myself wondering what the heck an “excrusion” is. The illustrations could be much better. This plate is well-engineered and sturdy. Using this plate, it is much easier to get an accurate cut because the no chip strip tells you where the blade will cut as opposed to not using the saw plate and measuring the distance from your circular saw’s blade to the edge of the edge clamp. I still use my NGX Edge saw guide as its a great substitute for lugging big boards across a table saw. The saw must be mounted perfectly on this plate for smooth and clean cuts. Made in China.

Petra West (verified owner) –

I had a problem with the non-chip strip; it was pulling away from the metal and adhesive after I installed it. I contacted the manufacturer and they immediately sent a replacement.

Chandler Barrows (verified owner) –

My son wanted this for a project he had, I thought he didn’t need it. I was surprised how handy it was and easy to use. I wouldn’t think of cutting a board without it now.

Monroe Brown (verified owner) –

It is just what I wanted. It grips firmly and doesn’t shift when cutting my plywood

Leilani Lubowitz (verified owner) –

So glad I have one of these. While I admittedly haven’t used it much, it has been great the handful of times I have put it to use. Cuts now come out perfectly straight, which was always a struggle when simply following a line or using a makeshift guide out of a straight edge and clamps. I also own the saw plate for this guide but wasn’t sure that the blade and edge were parallel nor convinced that the saw would stay firmly in place, so I never actually used it to cut anything. One of these days I’ll give it another shot.Back to the guide:. There’s 50″ between the jaws, so cutting a 4×8 piece of plywood across the shorter side isn’t a problem. Once tightened down, they grip the edges really well – no issues with them coming loose. Now, I’m not sure if this is a design issue or a feature, but once you loosen the clamp, you kind of have to fiddle with it in order to move the jaw. Kind of annoying but not a deal breaker. Another thing that bothers me is the fact that the critical parts (jaws, clamp) are made out of plastic. Should be fine for regular homeowner use, but longevity is a concern. One thing to note is that the clamp sticks out close to 3″ when it is tightened – just something to consider as this may be a problem if you have to set this up on the floor.

Grant Ankunding (verified owner) –

Exactly what I needed for rip cuts without the need of a track saw

Edmund Altenwerth (verified owner) –

They may feel kind of cheap, but they function really well. A+

Jackie Walter (verified owner) –

BORA 5-Piece Clamp Edge Saw Guide. Well built and nice features. When the extension is added, it can handle an eight foot piece of plywood. I dropped this product down a point because the instructions could use a lot more detail. Especially on installing the non-chip strips. Took me a while and a phone call to figure it out. First, straighten the strips out as much as possible. Second, the blue covering needs to be removed from the double sided tape. If your not careful, you’ll remove the tape along with the blue covering. One strip on each guide. Make sure the strip is on the same side of each guide. The side of the strip that has the tape goes on one side of the bottom of the guides (lower step on bottom). When the strip is installed, the tape side of the strip should be level with the upper step of the guide. The other edge of the strip should overhang the edge of the guide. The saw should be used on the side of the guide with the strip attached (overhang). Mounting the saw to the saw plate was easier and is adjustable in all directions. I stored my saw with the plate attached. The adjustible clamp holds the board tightly and gives you a ridgit, straight guide to cut on. Can be used with or without the sawplate. Using the saw plate is easier.

Aiyana Schimmel (verified owner) –

I have a few different clamps like this. This one is by far the best.

Enrique Nolan (verified owner) –

This clamp/guide is invaluable for table saw free environments. I couldn’t recommend it enough!

Darius Herman (verified owner) –

Excellent alternative to buying a track saw system. I already had an old circular saw that was collecting dust, so it was nice to be able to put it to use. It does require some setup, so make the extra effort so your cuts are straight and true.

Cade Smitham (verified owner) –

Boro NGX 5-Piece Clamp Edge Deluxe Set is an excellent way to cut sheet-goods and other tasks. The set consists of two guide rail pieces to handle 4 x 8 panels. One aluminum guide is used to cross-cut the four foot side with a 50-inches long track. For the rip cut, add the second 50-inch guide extension to the first guide for a 100-inch length, a little over 8-feet long. The two set of tracks are held together securely with metal bars and four screws. The track is then laid on top of the supported panel and two edge clamps on each side, under the guide, are easily tightened to give a rock solid grip onto the panel edges. Two included track clamps are also included if you want an angle cut, any angle can be cut up to 90-degrees is possible. You can cut full 4 x 8 panels or smaller sizes easily with this setup. The circular saw making the cut can run along the edge of the aluminum track guide or attached with the provided saw sled that slips into the aluminum guide securely in a groove. Once the saw is mounted to it runs along a groove in the guide preventing the saw from wandering, assuring a straight cut.. It works similar to a track saw. Included in the set used with the sled plate are two lengths of 3M non-chip strips that attach to the bottom for riding on the panel. It minimizes any top edge tear-out for a cleaner cut. This is useful for bonded veneers; although not needed for other panels like MDF or construction grade plywood. The sled is made of sturdy plastic with honeycomb reinforcement that is rigid, doesn’t flex. The saw is held-down with hold-down screws and clips, can be positioned and removed easily. Bora also offers, optionally, other tool sled plates to hold routers and a jig saws that work with the track guide, too.I own a portable table-saw and continue to prefer Bora’s system for breaking down sheet-goods resting on two saw horses. It is safer than handling large sheets alone on the table saw. It gives me more control making the cut safe and clean.