BORA NGX 36 in. Clamp Edge Saw Guide

$53.09

Do all your hardest jobs easily with the help of this amazing BORA NGX Clamp Edge Saw Guide. Used for both mild and stainless steel punching.

In stock

Description

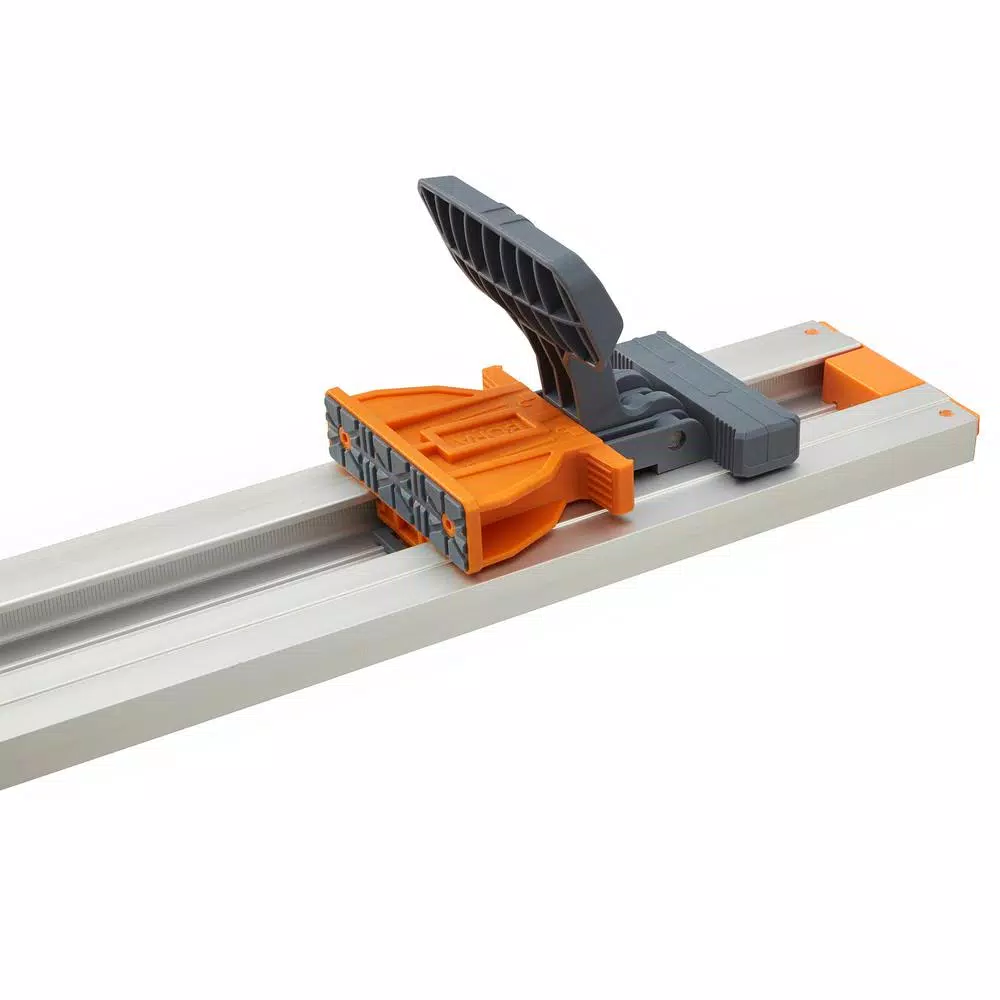

The NGX Clamp Edge System makes it faster and simpler to break down sheet material rip and crosscut boards with clean, accurate cuts every time. NGX gives you track saw-like precision without the hefty price tag. Its never been easier to rip, cut, and break down material than with the all-new NGX Clamp Edge System. No more fumbling with adjustable clamp ends on opposite sides of the straight edge the adjustable clamp is connected to the handle. Simply hook the Clamp Edge across your board, line it up with your cut, and clamp it down all without moving your feet.

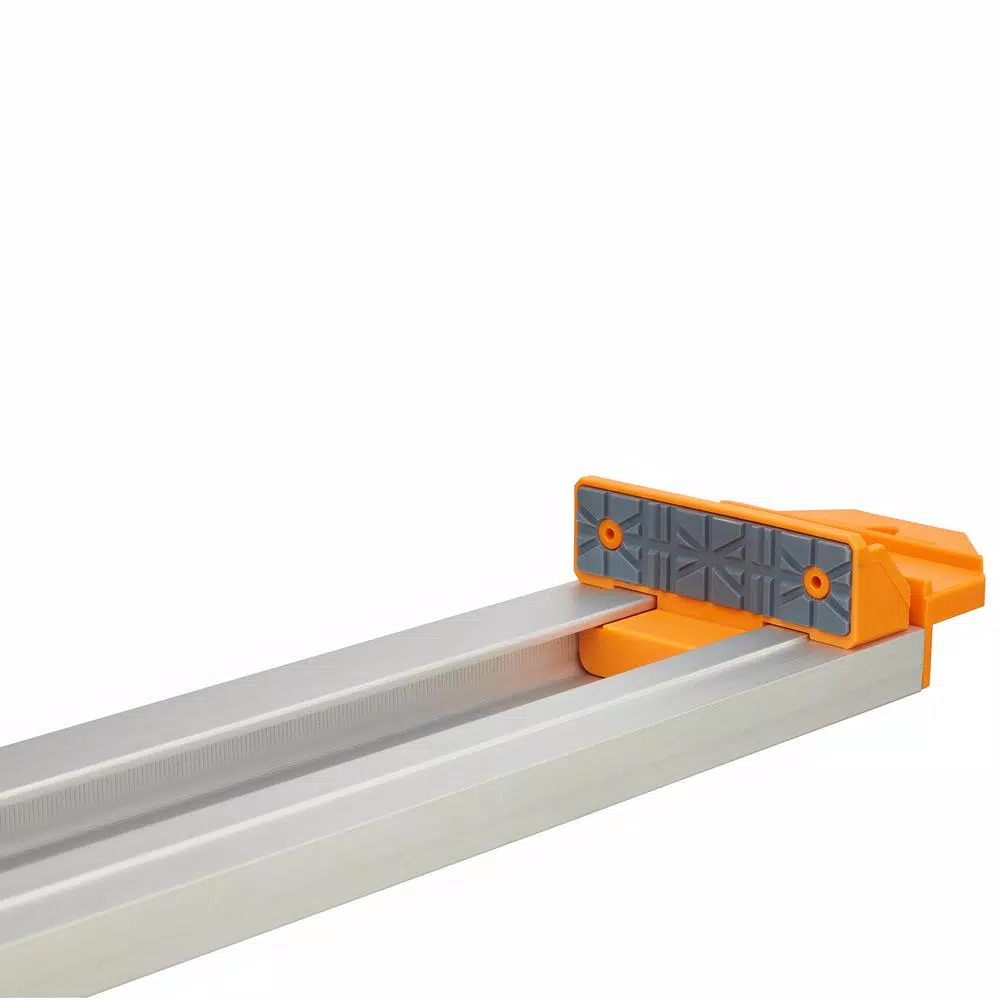

- Clamping end moves with handle for easy adjustability from 1-side

- Locking handle grabs work surfaces for a secure grip that wont budge

- Easily increase length up to 86 in. with aluminum extensions

- Made of heavy-gauge, rigid aluminum for extreme durability

- Use with circular saws, routers, jig saws, and other portable power tools

- Part of the NGX Clamp Edge System to cut and rip sheets and boards

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 1.8 lbs |

|---|---|

| Dimensions | 44.00 × 3.00 × 2.00 in |

| Color Family | Silver |

| Ideally Used With | Circular Saws |

| Material | Aluminum |

| Model | 544036 |

| Power Tool Accessory Type | Other Accessory |

| Product Length (in.) | 36 |

| Tools Product Type | Other |

Reviews (86)

86 reviews for BORA NGX 36 in. Clamp Edge Saw Guide

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Tracks

General Tools 20 in. Heavy-Duty T-Track Professional Face Frame System

Model# 856TSaw Tracks

Model# TTSAGSaw Tracks

Model# DWS5022Saw Tracks

Model# 196953-0Saw Tracks

WEN 27.5 in. Track Saw Track Guide Rail with Adapters (2-Pack)

Model# 36027-2PSaw Tracks

Olson Saw 12 mm x 3/4 in. Guide Block for 14 in., 16 in. and 18 in. Imported Band Saws (4-Pack)

Model# CB50055BLSaw Tracks

Model# SM840Saw Tracks

Model# 198673-2

Lila Gleason (verified owner) –

Exactly what I needed for rip cuts without the need of a track saw

Trenton Jones (verified owner) –

I have this and the extension for a 104″ reach to rip sheet goods. But buying the two thinking you are going to reconfigure each time you “rip” and “crosscut” a 4×8 sheet is not going to work–too long and too much wear on the parts. It holds well, but takes time to set up straight. A little pricey!

Sabryna Dietrich (verified owner) –

Worked really well

Vanessa Wilderman (verified owner) –

My son wanted this for a project he had, I thought he didn’t need it. I was surprised how handy it was and easy to use. I wouldn’t think of cutting a board without it now.

Corrine Schulist (verified owner) –

BORA NGX Clamp Edge Saw Guide is a quality guide for circular saws, routers and even jig saws. It is made of heavy duty aluminum with an excellent clamping method that secures the guide rail above on top of the sheet goods with an edge clamp. The handle to tighten the guide is easy to use by one person and doesn’t budge at all when used with the saw. A secure fit is critical in preventing the saw from wandering off the cut. It doesn’t happen often, but it can ruin the cut and I’ve done it. I had a shorter Rockwell guide and it wasn’t nearly as well done as this one. There is an optional second section that can be joined to this 50-inch rail extending it to handle rip cut for sheet length goods, too.An advantage of this system is the excellent options that can be had, sold separately, to make it even better to use. I used my rail with their universal circular saw plate that mounts the circular saw using hold down clamps. The plate can then be slipped into the slots on the top of the aluminum rail securing it. It then works more closer to a track saw. Included with the plate is a length of 3M non-chip strip to attach to the bottom of the plate along the saw blade, reduces any top edge tear-out for a cleaner cut. This is useful for bonded veneers. Bora has similar plates for routers and a jig saws that slip into the slots on the top of the rail. Finally, I was at initially concerned about the plate being plastic. It is thick plastic and feels substantial for DIY work, all well done. I tried the rail and saw plate out with my Milwaukee cordless circular saw and it fit nicely after about five minutes of making set-up adjustments. You have to slide over the hold down rail that has two clamps and make it exactly parallel to the saw blade and lined up on the plate’s blade guide. It is all easily done with allen screws and a flat slotted screwdriver. Really not a big deal, but the saw has to be accurately lined up to get a straight cut. I didn’t use their non-chip tape and didn’t need it for the MDF used. Overall, this is an excellent tool for crosscutting sheet goods. The rail alone is first rate and with the circular saw plate it goes quicker and is more accurate. I also own a small work-site table saw and when working alone prefer this method to cut sheet goods on two saw horses. It just is safer with my experience level and equipment setup. I feel the Bora system however you’ve configured it is a good value for DIY-ers to other methods.

Vern Schimmel (verified owner) –

This appears to be well-made but I never had to use it after I bought it.

Randal Deckow (verified owner) –

This is a very useful tool overall, but the adhesive on the chip strip is weak and didn’t last for two days. Since the strip is not a necessary item, I can’t complain too loudly since I really like the rail and bracket.

Anthony Smith (verified owner) –

This guide makes cutting sheets of plywood, oriented strand board and composite siding much easier. In my opinion, this is a must have for the DIY handyman. Matched with the saw sled, you can cut straight edges up to fifty inches. My biggest concern is that the saw sled is made of plastic and I don’t know how much rough use it can handle. I have always had a problem free cutting sheet material squarely and this set up will help accomplish precise, straight edges.

Libbie Kuphal (verified owner) –

Great for cutting sheet goods. The only downside is that it’s not easy to connect & disconnect to the extension.

Rene Kuhlman (verified owner) –

It’s a bit difficult to set up. A lot of folks recommend using it with a dedicated saw and keeping that saw attached to the plate, which I think would help. But it makes excellent straight cuts, and sets up much faster than my old straight edge.

Gayle Thiel (verified owner) –

I deserve a hard kick in the pants – for not getting one of these tools years ago. Like many DIYer, I have struggled with using a piece of extruded aluminum or angle iron and a pair of clamps to cut straight lines (hopefully) in large sheets of material. The setup was time consuming and the cut wasn’t always straight. This tool virtually eliminates both of those problems. Very easy to use – with excellent clamping force – and sturdy enough to always get straight cuts. They also have a saw adapter (purchased separately) that holds the saw in a tray which slides along on top of the saw guide – eliminates the possibility of the saw drifting off track. This tool is a must have for any volume of 4X8′ cutting.

Natasha Armstrong (verified owner) –

So my Dad had a guide for his circular saw which was two pieces. It was a pain to setup & get straight. I ordered this guide because it was one piece & can be setup with one hand as I demonstrate in the video below. When cutting thick plywood, using one of these guides is way easier & more accurate than trying to rip the material on a table saw or using a circular saw freehand. Mine came with a sled, which can be used in conjunction with the guide to make the cutting easier & more accurate.

Christopher Walter (verified owner) –

Perfect for cutting ACM panel on my drafting table

Garrison Keebler (verified owner) –

Easy to use guide clamp that makes accurate cuts quickly. Saw base is easy to mount to your saw and easy to dial in. Great setup for ripping and cutting down plywood.

Kendra Hoeger (verified owner) –

I love the clamp and rails.I was impressed with this edge clamp set. I have wanted one for a while now and was happy to get this one. The 50″ rails (2) have a good weight to them and when connected to make a 100″ single rail is very sturdy.I gave this set 4 stars because I didn’t like the setup of the saw attachment. I watched a couple of You Tube videos about connecting the saw to the plate and then to the rails. The directions included with the set also were a little vague for the first time user. After watching the videos, I decided to just use the rails. I do plan on using the saw plate attachment in the future, but didn’t want to take the time to figure out all the measurements. I will update my rating to 5 if I find the saw plate makes a great improvement. I did like the two extra clamps that are included in this set. I’m planning on building a shed in the near future and already see that some of the cuts will be improved with the versatility of these two clams to secure the rails. I am happy with this set and will be using it many times in my future. It’s a great buy and I want to learn how to use the saw plate. I think it will be a welcome piece once I figure out how to use it.

Abdullah Harvey (verified owner) –

Sticks to the guide rail but overall Good saw plate

Deanna Jaskolski (verified owner) –

I really could have used this when I was building 4 barn doors for my basement. But I have two more to go and this will make the job much easier. It’s a pretty simple setup – the bars clamp easily to the work piece. And if it’s just straight cuts you can get away without the sled, just keep your saw pressed up against the track. The sled is a little tricky to attach straight but that’s more due to me being new to using a track saw. Couple of YouTube videos later and it was easy to figure out. And using the sled will ensure the saw doesn’t stray. All parts are very sturdy, very little flex in the bars. And the additional track clamps are a great addition – you can use bar clamps or C clamps, but to have clamps purpose built for this is much better. All in all, this is hands down better than screwing in scrap pieces of wood to serve as my guide and then having to fill holes. My only complaint, like others, is the instructions. Definitely not the easiest to follow.

Jayme Waelchi (verified owner) –

Thought I was getting Justin and guide clampdown style for for power saw ended up getting a bonus edge guide which my circular saw fits into which I thought was rather nice used it a couple times so far seems to work rather well there’s a chip strip that goes with the text chance to stop the wood from chipping back if you’re doing doors so you don’t chip the edges makes it look clean would recommend this for anybody replacing or buying a new Edgcote clampdown style

Elmira Mann (verified owner) –

It is just what I wanted. It grips firmly and doesn’t shift when cutting my plywood

Reginald Kessler (verified owner) –

I had a problem with the non-chip strip; it was pulling away from the metal and adhesive after I installed it. I contacted the manufacturer and they immediately sent a replacement.