BORA NGX 36 in. Clamp Edge Saw Guide

$53.09

Do all your hardest jobs easily with the help of this amazing BORA NGX Clamp Edge Saw Guide. Used for both mild and stainless steel punching.

In stock

Description

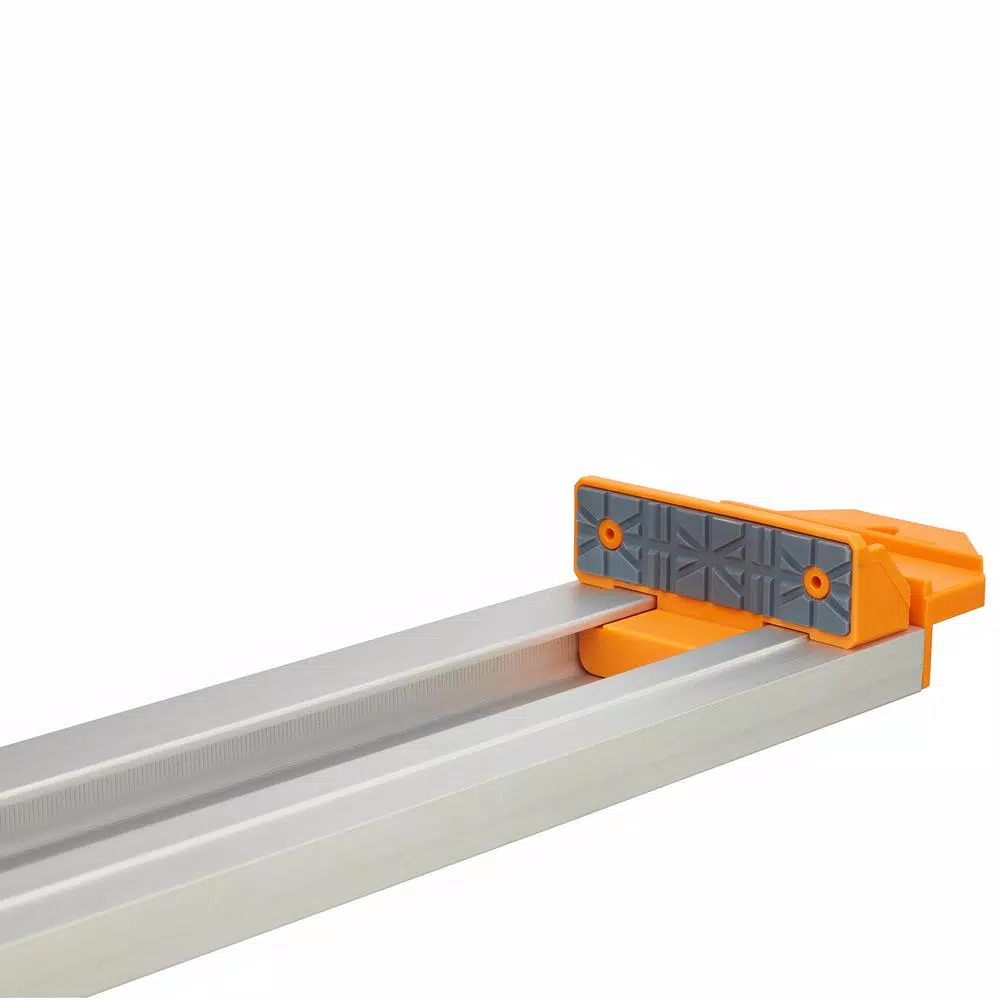

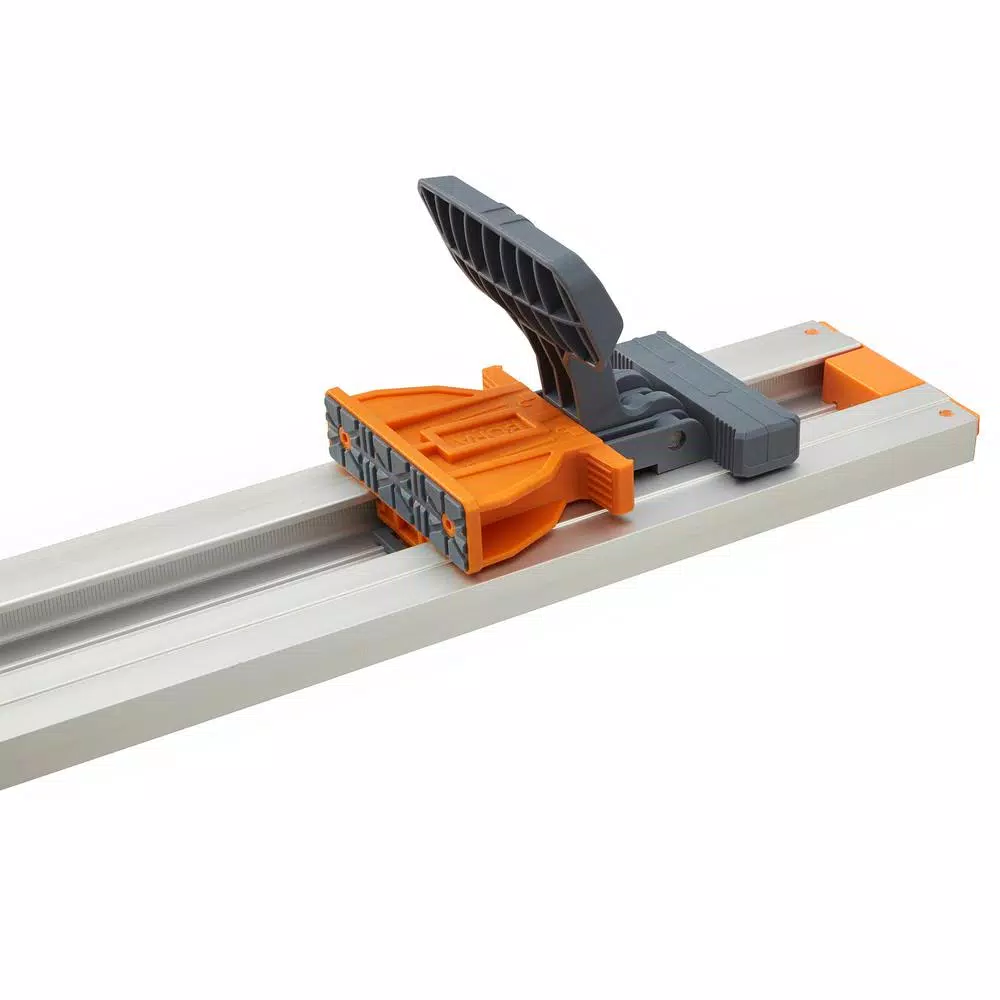

The NGX Clamp Edge System makes it faster and simpler to break down sheet material rip and crosscut boards with clean, accurate cuts every time. NGX gives you track saw-like precision without the hefty price tag. Its never been easier to rip, cut, and break down material than with the all-new NGX Clamp Edge System. No more fumbling with adjustable clamp ends on opposite sides of the straight edge the adjustable clamp is connected to the handle. Simply hook the Clamp Edge across your board, line it up with your cut, and clamp it down all without moving your feet.

- Clamping end moves with handle for easy adjustability from 1-side

- Locking handle grabs work surfaces for a secure grip that wont budge

- Easily increase length up to 86 in. with aluminum extensions

- Made of heavy-gauge, rigid aluminum for extreme durability

- Use with circular saws, routers, jig saws, and other portable power tools

- Part of the NGX Clamp Edge System to cut and rip sheets and boards

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 1.8 lbs |

|---|---|

| Dimensions | 44.00 × 3.00 × 2.00 in |

| Color Family | Silver |

| Ideally Used With | Circular Saws |

| Material | Aluminum |

| Model | 544036 |

| Power Tool Accessory Type | Other Accessory |

| Product Length (in.) | 36 |

| Tools Product Type | Other |

Reviews (86)

86 reviews for BORA NGX 36 in. Clamp Edge Saw Guide

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Tracks

Olson Saw 12 mm x 3/4 in. Guide Block for 14 in., 16 in. and 18 in. Imported Band Saws (4-Pack)

Model# CB50055BLSaw Tracks

Model# KMS8000Saw Tracks

Model# 71128Saw Tracks

Model# KMA2685Saw Tracks

Olson Saw 3/16 in. x 3/4 in. Band Saw Guide Blocks for Most 56-1/8 in. Band Saws (4-Pack)

Model# CB50080BLSaw Tracks

General Tools 20 in. Heavy-Duty T-Track Professional Face Frame System

Model# 856TSaw Tracks

Model# SM844Saw Tracks

Model# 196664-7

Terrell Leannon (verified owner) –

Excellent guide and easy to use. When the two parts are assembled, they formed a straight edge that was verified with a level. Highly recommended.

Alvah Hammes (verified owner) –

This clamp edge was very easy to use.

Percival Langworth (verified owner) –

Outstanding way to make smooth straight cuts across sheeting, like plywood, particle board and paneling. The saw plate is well designed to accommodate many different manufacturers circular saws. I was easily able to attach the 2 saws that I have. The saw plate slides along the saw tracks to provide for easily sawing sheeting. The first section of track is long enough to fit across up to 50″. The second section of track fits on the end of the first to extend the length of cut to 100″. 4 screws are used to attach the 2 sections together. The tracks are made from rigid aluminum and the saw plate is made of plastic. even though it was made of plastic it was durable, rigid and held my 2 saws tightly in place. The only negative I found was somewhat vague installation instructions. Their website didn’t provide a lot more detail. Their customer service did provide a link to video and I ran across a really good one on the internet. Try searching Bora NGX.

Veda Wilderman (verified owner) –

Bought this specifically to cut up plywood safely. The Bora NGX clamp definitely does this. For the price, this is a great little unit. It cuts spot on every time. Like any tool, you have to understand how it works and be aware of a few things to ensure it performs properly. On the NGX clamp, here are some things to keep in mind. Note, these are not in any way flaws. 1.) It does take about 15 minutes to connect your circular saw and dial the settings in to ensure adequate space between the cutting blade and the material. I have a DeWalt DWE575 and dialed it so the clamp is exactly 9/16 from my cut line. 15 minutes is not a lot of time, its easy. Do a few practice cuts. I recommend getting it dialed in to an exact measurement and there are markings on the slide piece to help you do this. Also recommend, clamp the top first, then do the 2 side clamps.2.) In the times I tried to use the right angle guide, it has not performed well. I bought the Premier set mainly because it was the only item available as the other parts (bought separately) were out of stock. In other words, I wouldn’t buy the Premier for this one part.3.) When cutting, be sure to put pressure on the right side of the guide. This ensures there is less blade deflection as you cut. 4.) Some folks complain the clamp down slide gets stuck. The trick is this… The gray handle and the orange edge has to come together in order to slide it. Simple. If it’s not sliding… just push them toward each other, you’ll feel a little click and it slides great.5.) Using the extension piece takes practice to ensure it’s spot on straight once the 4 screws are screwed in tightly. I find that screwing them in a little then pushing both slide components together and then screwing in the screws fully works best. Always check to make sure this is straight, common sense.6.) Some folks have mentioned the plastic construction of the base plate and clamp down. I’m not too worried about this. It’s pretty decent grade plastic. You’ll definitely get a few years out of this tool before anything breaks. If it does, just replace the part. Every tool wears.7.) The instructions… ha, this is one area that could use improvement. However, if you know how to use a circular saw and have actually changed out blades, the setup is pretty self-explainatory. Plus there’s plenty of videos out there.To close, even when I do get a table saw, I will still use the Bora NGX to cut full size plywood down to a more managable size. It is the safest way to do this and watching videos of people doing this on a table saw is pretty funny when you look at their eyes cause they know are uncomfortable.

Jany Roberts (verified owner) –

I am reviewing the saw plate, and the 100″ NGX two piece saw guide. Pros1) Easy to set upCons1) The saw plate is plastic. The buckles that hold it to your saw are aluminum, but they are secured to a plastic base.2) The saw guide clamping mechanism is plastic. There’s no way that clamp is going to stand up to years of use 3) It takes quite a bit of force to securely clamp the guide to your work piece, which tends to move the guide a tiny bit from your proposed cut line. You can back off the clamp pressure if you want, but then you risk the guide moving during your cut.4) When mounted on the saw guide, the saw plate rocks a bit from side to side. You can see this on YouTube videos. Since it doesn’t make contact with the wood, it is unstable and will not produce an accurate 90 degree edge5) The saw plate comes with a 55″ cutting strip, but the 100″ guide doesn’t include any strip. So basically, if you want to make clean cuts, you need to spend another $20 for an addition Non-Chip Strip. Not cool Bora!6) The two 50″ cutting guides are made of a thin gauge aluminum. It’s not a problem where cutting is concerned, but just shows how quality took a back seat to profits.Here’s the bottom line;If it came with a 100″ cutting strip, had metal clamps on the guides, and was priced under $100, I’d give it an additional star because the design is kind of cool. As it stands now, it’s an overpriced, over-hyped, novelty item. I returned mine after one use, and decided to make my own with 80/20 aluminum.

Donald Walter (verified owner) –

BORA 5-Piece Clamp Edge Saw Guide. Well built and nice features. When the extension is added, it can handle an eight foot piece of plywood. I dropped this product down a point because the instructions could use a lot more detail. Especially on installing the non-chip strips. Took me a while and a phone call to figure it out. First, straighten the strips out as much as possible. Second, the blue covering needs to be removed from the double sided tape. If your not careful, you’ll remove the tape along with the blue covering. One strip on each guide. Make sure the strip is on the same side of each guide. The side of the strip that has the tape goes on one side of the bottom of the guides (lower step on bottom). When the strip is installed, the tape side of the strip should be level with the upper step of the guide. The other edge of the strip should overhang the edge of the guide. The saw should be used on the side of the guide with the strip attached (overhang). Mounting the saw to the saw plate was easier and is adjustable in all directions. I stored my saw with the plate attached. The adjustible clamp holds the board tightly and gives you a ridgit, straight guide to cut on. Can be used with or without the sawplate. Using the saw plate is easier.

Kellie Okuneva (verified owner) –

It is a nice product but the clamp pressure is not that strong, it can slip and will if there is any pressure from the saw. Also the height or thickness is a little to much who’s had only allows the skill saw to be used in one direction. Slipping while clamp is set is main concern.

Cecilia Kemmer (verified owner) –

Excellent saw guide, an important tool if you dont own a table saw or cant lug a large sheet of plywood across a table saw. It is very easy to use and the clamp is strong. The clamp has a temporary setting before you lock it into place. It locks very tight and may bow up so you should leave the clamp a little loose before cinching it down. It holds onto the piece nicely. For sawing, all you need to do is know the distance from the edge of you saw plate to the cut (mine is 4″) and set the clamp that distance away. The clamp can fit easily across 4 foot sheet and is durable as well. It can also be used for scoring drywall. This is a great tool to have in the workshop and hangs easily on a nail for storage. In the past I have used my most straight piece of wood and clamps. This saw guide saves me time and hassle.

Jessyca O’Hara (verified owner) –

This clamp edge guide is a fantastic addition to any shop! It is surprisingly light weight, made from extruded aluminum, but very durable. The clamps are a strong plastic material, and the clamp surfaces that touch the material to be cut have a rubber, non-abrasive grip surface.The clamp is ~50″, easily able to be used to rip a full sheet of plywood. One of the clamp ends slides on an internal track making it easily adjustable. That means the clamp can be used to cut any width of wood from ~48″ to 3″ wide. Overall a very useful tool for making long, straight cuts!

Christ Casper (verified owner) –

Saw plate gets hung up on track guide joint screw heads.

Kris Weissnat (verified owner) –

This is a strong, easy to operate clamp with a versatile saw guide attachment (Model 544050, Made in China). The clamp is 50” in length, long enough to use on a 4′ x 8′ piece of plywood to cross-cut it. The clamp adjusts by sliding the clamp end, but the mechanism must be FULLY disengaged or it will not slide. As with most clamps, the edge will not automatically be square to the clamping surface so use a square to align the clamp. The clamping force is STRONG, and takes a bit of muscle to lock/unlock the clamp. It’s enough to actually bend 1/4” plywood (see photo) so it will hold tightly during use. The clamp has two parallel slots on it that are perfect for holding 1/4” bolts, including toilet bolts, meaning the clamp can be used with homemade jigs. There is a nice hanging hole at the top of the clamp. This clamp is much better than either of the other two 50” clamps I own and will get a lot of use.I normally cut plywood by just sliding my circular saw against the edge of the clamp, and usually don’t drift from the clamp. The Edge Saw Guide virtually eliminates the chance of drift by riding BOTH sides of the clamp. The base adjusts for most saws (right or left-handed) and locks onto the saw with three clamps. Adjustment is a one-time task, requiring a 3mm hex (allen) wrench, which was not supplied. Unfortunately for me, there was no way to adjust the clamping bolts to engage on a flat spot on my saw base, which has a grid pattern, so the grip was tenuous at best. The guide comes with a strip of plastic to be installed as a “non-chip” edge, preventing the wood from splintering along the cut (similar to a zero-clearance throat plate on a table saw). I chose not to install mine, as it limits the clamps use as an edge guide for other saws and/or router. The clamp and guide work perfectly without it, but the cut itself might not be as clean on the upper surface.For my money I would buy the clamp and skip the Edge Saw Guide, especially since it doesn’t fit my particular circular saw as well as it might fit others. It’s a good quality accessory, but doesn’t add enough value for me.

Kaycee Runte (verified owner) –

Works great especially with worx exactrack circular saw. Cuts through 4 x 8 plywood straight every time!

Berneice Boehm (verified owner) –

This clamp/guide is invaluable for table saw free environments. I couldn’t recommend it enough!

Julius King (verified owner) –

I have used this quite often. The only problem that I had was with the base when I attached my saw I was trying to cut the edge of my countertop which was 1 1/2″. My 7 1/2″ blade wouldn’t cut deep enough to get the whole edge.

Ima Stokes (verified owner) –

They may feel kind of cheap, but they function really well. A+

Melyssa Denesik (verified owner) –

Super handy for trimming doors to fit after a whole home flooring project.

Dylan Stroman (verified owner) –

This Bora clamp deluxe just make my jobs so much easier I do carpentry, cabinets, and other wood work, now I can make my cuts much more straight, or in any angle, the with extension you can cut a plywood 8 feet long or you can take the extension off and do smaller cuts, the saw plate is included and so easy to attach a circular saw, you can move it to different measurements positions to make your cuts, definitely I will recommend this Bora clamp deluxe for smaller or big jobs

Crawford Simonis (verified owner) –

This is one of those tools I never knew I needed until I tried it. I’ve always used a couple of clamps and something with a “straight” edge to try to get a straight line. That involved finding something straight and of course running from side to side of the sheet to adjust the clamp. This tool takes all that extra effort away. Set it where you need it and quickly clamp it at one end, then cut. Done. It’s very light, very easy to maneuver, and the adjustable clamp slides easily in the track.Pair the clamp with Bora Saw Plate accessory (https://www.homedepot.com/p/BORA-NGX-55-in-Saw-Plate-with-Non-Chip-Strip-544001/311799074), and move your saw effortlessly along the track. These clamps and accessories basically turn your circular saw into a unisaw!

Tracey Grady (verified owner) –

This guide is easy to use for making long crosscuts of plywood. Very light, but held up well as I cut up seven sheets of plywood to build four cabinets

Delmer Hamill (verified owner) –

I set this up today to test it out, First I removed my Craftsman circular saw from another brand track saw base. Then I installed it on the Bora base using the instructions that came with the set. First problem was the instructions are not the best but still able to figure things out. I set the tack across my table saw and placed the base on the track then the saw on the base. This let me adjust it to the track so the saw is not skewed on the base. After installing the saw on the base I installed the tear out strips. They were very easy to install and fit perfect to the track. Then I placed the base with saw on the track again and checked that the blade would ride along the edge of the tear out strip all the way down both pieces of track.. Its now ready to use. I took a piece of 3/4″ red oak plywood that was 76″ long and 24 1/2″ wide and cut 1/2″ off the whole langht so I had 76″ X 24″. I don’t have alot of room to work so I would rip my sheets of ply out side using my truck and a saw horse. but this time I just layed it across my table saw and clamped it down and cut it. The two piece of track connected together and the bora track layed down and clamped with the slide clamp only it was solid as a rock it was not moving. I placed the base and saw on the track and made a perfect cut and my work piece was nice and clean no tear out at all. Now with it 24″ wide I needed 2 pieces 28″ long so I took off the extension track and just use the 1 piece to cut across the width to cut off 28″. Now the left over piece I took and cut off another 28″ langth with my table saw then I compared the 2 pieces and they both were perfect and match up they both were square to each other. I find the base rides on the track very smooth and it does not skew any when you stop and start again. There is no slop in the base when riding along the track. I did not use the 2 track clamps at this time but thay are great I checked them out and thay adjust great they fit the track with no problems and I know I will use them alot in the future. Now with all that said the only thing I can see a problem with is the nuts on the bottom of the base. when I went to adjust the lock down track on the base the nuts turned in the grove. This should be a long nut made with flat stock so it can’t turn in the grove not a hex nut that will ware the plastic if its tighten and loosen to maney times. For me its ok I am leaving the saw set up. Even with the one flaw above this is easer and better than the other brand I have been using that I had to go buy clamps to hold it down to keep it from walking on cuts. Its also harder to set up for long cuts so The Bora clamp edge deluxe set is a Plus plus for me. Now all I need is a Bora Centipede so I dont have to use my truck as a table.