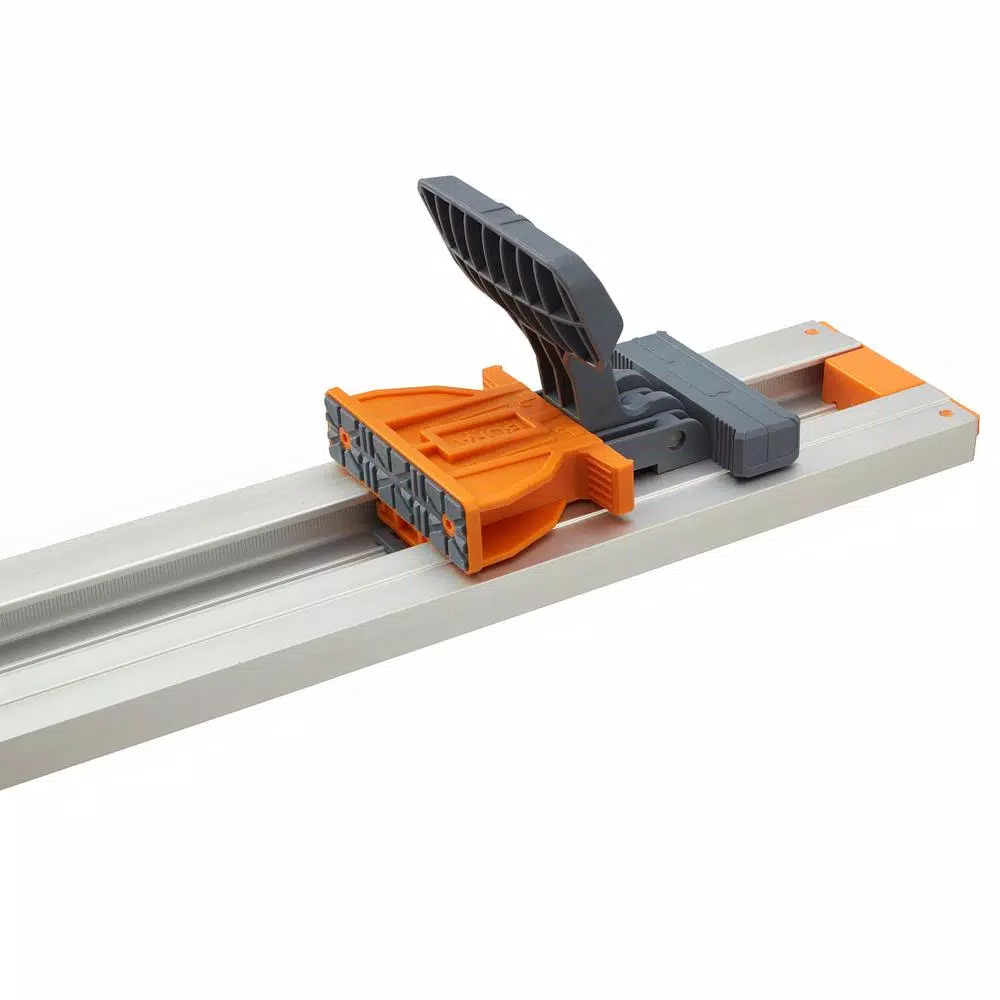

BORA NGX 50 in. Clamp Edge Saw Guide

$49.97

Easily achieve straight and precise cuts on any tough surface by using this amazingly powerful BORA NGX Clamp Edge Saw Guide. Ensures lasting durability.

In stock

Description

The BORA NGX Clamp Edge saw guide makes it easy to achieve straight and precise cuts with your circular saw. Cutting large sheets of plywood or MDF materials has never been easier. Just adjust the clamp to the desired cut dimension and lock it in place. During the cut, your circular saw rides along the edge of the BORA NGX saw guide resulting in a professional, accurate cut. And, best of all with the BORA NGX Clamp Edge, you position, adjust and lock the clamp all from the same end. This convenience feature eliminates the need to walk around to the opposite side of the material to adjust or lock the clamping mechanism.

- Constructed with heavy-gauge aluminum for extreme duty

- T shaped locking handle slides up and down the guide to fit material being cut

- Locking handle linear motion rotates and locks in line with the aluminum extrusion for accuracy

- Grabs and locks to the work surface for a secure edge that won’t budge

- Easiest way to make precise, track saw like cuts

- Full 50 in. of clamping capacity

- 3 in. W extrusion is equipped with 2 slots which accept the head of a 1/4 in.-20 bolt, great for attaching shop built jigs or fixtures

- Use with circular saws, jig saws and routers or anytime a straight edge guide is needed

Additional information

| Weight | 2.3 lbs |

|---|---|

| Dimensions | 1.90 × 3.20 × 57.90 in |

| Color Family | Assorted Colors |

| Ideally Used With | Circular Saws |

| Material | Aluminum |

| Model | 544050 |

| Power Tool Accessory Type | Other Accessory |

| Product Length (in.) | 4 in |

| Tools Product Type | Power Tool |

Reviews (86)

86 reviews for BORA NGX 50 in. Clamp Edge Saw Guide

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Tracks

Model# 198673-2Saw Tracks

Model# 196953-0Saw Tracks

WEN 27.5 in. Track Saw Track Guide Rail with Adapters (2-Pack)

Model# 36027-2PSaw Tracks

Triton 2 in. x 27.5 in. Track Pack with Connectors for Track Saw

Model# TTSTPSaw Tracks

Model# SM844Saw Tracks

Model# DWS5022Saw Tracks

Model# 196664-7Saw Tracks

Olson Saw 3/16 in. x 3/4 in. Band Saw Guide Blocks for Most 56-1/8 in. Band Saws (4-Pack)

Model# CB50080BL

Pamela Toy (verified owner) –

This Bora 50-inch Clamp Edge Saw Guide is a welcome addition to my woodworking tools. I bought a similar small clamp edge type guide many years ago at a woodworking show in Phoenix, but this Bora clamp edge is far superior to that one. First of all, the Bora NGX is 50 inches long, so it can clamp all the way across a 4 x 8 sheet of plywood. (My old clamp edge guide is only 26 inches long, so it has limited use as a saw guide.) The Bora clamp edge aluminum rail is slightly more than 1/2 inch thick, so it is very sturdy.The main rail of the Bora NGX clamp edge is made of extruded aluminum and the clamping mechanism and end stop are made of some kind of sturdy molded thermo-plastic. When released the clamping end slides easily in the double track slots of the aluminum rail. When you get it in position against the edge of your plywood, a simple flick of the T-handle locks the clamp edge in place ready to guide your saw. Bora sells a separate NGX saw plate that can ride on top of the clamp edge rail or you can just allow for your saw’s blade offset and let the saw’s edge be guided by the clamp edge rail.My only complaint (which is a pet peave of mine) is that Bora slapped a UPC sticker on the clamp edge rail where it meets the cardboard packaging (see photo) that was very hard to remove. It took me 15 minutes of soaking the UPC label remnants with WD40 and scrubbing with paper towels to remove the label adhesive without damaging the aluminum rail’s finish. Sterlite, who makes plastic storage boxes, manages to make labels that stick to the product but are very easy to remove without leaving adhesive residue, so why can’t other manufacturer’s follow their lead?

Kiara Becker (verified owner) –

BORA 5-Piece Clamp Edge Saw Guide. Well built and nice features. When the extension is added, it can handle an eight foot piece of plywood. I dropped this product down a point because the instructions could use a lot more detail. Especially on installing the non-chip strips. Took me a while and a phone call to figure it out. First, straighten the strips out as much as possible. Second, the blue covering needs to be removed from the double sided tape. If your not careful, you’ll remove the tape along with the blue covering. One strip on each guide. Make sure the strip is on the same side of each guide. The side of the strip that has the tape goes on one side of the bottom of the guides (lower step on bottom). When the strip is installed, the tape side of the strip should be level with the upper step of the guide. The other edge of the strip should overhang the edge of the guide. The saw should be used on the side of the guide with the strip attached (overhang). Mounting the saw to the saw plate was easier and is adjustable in all directions. I stored my saw with the plate attached. The adjustible clamp holds the board tightly and gives you a ridgit, straight guide to cut on. Can be used with or without the sawplate. Using the saw plate is easier.

Torrance Kutch (verified owner) –

Saw plate gets hung up on track guide joint screw heads.

Beverly Simonis (verified owner) –

Precise quick sheet cutting guide. Light, strong, well made and easy to use. Clamping NGX guide and bonus exact fitting saw plate allow time saving cuts. Especially for equal multiple sheet cutting. Clear consise instructions. Initial saw plate set up took a few minutes but once done allowed quick easy detach and reattaching of saw with quick release clamps. Guide clamps to hold securely for use with saw or saw plate. First task was squaring up plywood work surface, guide performed well, easily met expectations. Easy to set perpindicular using square then clamping in place for an accurate cut. The only issue was with the saw plate cut line indicator detaching after use. Likely knocked out. Inserting opposite way, more to my liking in use, care needs to be given when handling saw plate to prevent loss of cut line indicators. Selected the NGX guide for beadboard sheet cutting. Highly satisfied with guides ability to hold panel securely for precise clean cuts. Backing clamp slightly off panel allowed grip without bending for precise clean cuts. Guide quickly proved valuable for accurate quick sheet cutting but also as a straight edge and extension for level adding more value to the economical saw guide. A great DIY tool that performs very well. Highly recommend.

Ellen Doyle (verified owner) –

It’s straight and it locks. Feels pretty solid but doesn’t slide that smoothly. It can give one a false sense of security in thinking you are making straight cuts but you will need to double or triple check before you cut. When paired with the bora saw base plate it is even more the case to triple check your lines, measurements and fasteners as things can get out of adjustment after each pass. Overall can produce straight and accurate cuts but it will take a long time and adjustment(s).

Josiane Gerhold (verified owner) –

So glad I have one of these. While I admittedly haven’t used it much, it has been great the handful of times I have put it to use. Cuts now come out perfectly straight, which was always a struggle when simply following a line or using a makeshift guide out of a straight edge and clamps. I also own the saw plate for this guide but wasn’t sure that the blade and edge were parallel nor convinced that the saw would stay firmly in place, so I never actually used it to cut anything. One of these days I’ll give it another shot.Back to the guide:. There’s 50″ between the jaws, so cutting a 4×8 piece of plywood across the shorter side isn’t a problem. Once tightened down, they grip the edges really well – no issues with them coming loose. Now, I’m not sure if this is a design issue or a feature, but once you loosen the clamp, you kind of have to fiddle with it in order to move the jaw. Kind of annoying but not a deal breaker. Another thing that bothers me is the fact that the critical parts (jaws, clamp) are made out of plastic. Should be fine for regular homeowner use, but longevity is a concern. One thing to note is that the clamp sticks out close to 3″ when it is tightened – just something to consider as this may be a problem if you have to set this up on the floor.

Mireille Brakus (verified owner) –

This clamp edge was very easy to use.

Ronny Lemke (verified owner) –

Tried to use it over the weekend on a few sheets of plywood. It seems as if not completly square. There does not seem to be any adjustments to square it off perfectly.

Columbus Schulist (verified owner) –

So my Dad had a guide for his circular saw which was two pieces. It was a pain to setup & get straight. I ordered this guide because it was one piece & can be setup with one hand as I demonstrate in the video below. When cutting thick plywood, using one of these guides is way easier & more accurate than trying to rip the material on a table saw or using a circular saw freehand. Mine came with a sled, which can be used in conjunction with the guide to make the cutting easier & more accurate.

Dolores Hagenes (verified owner) –

Outstanding way to make smooth straight cuts across sheeting, like plywood, particle board and paneling. The saw plate is well designed to accommodate many different manufacturers circular saws. I was easily able to attach the 2 saws that I have. The saw plate slides along the saw tracks to provide for easily sawing sheeting. The first section of track is long enough to fit across up to 50″. The second section of track fits on the end of the first to extend the length of cut to 100″. 4 screws are used to attach the 2 sections together. The tracks are made from rigid aluminum and the saw plate is made of plastic. even though it was made of plastic it was durable, rigid and held my 2 saws tightly in place. The only negative I found was somewhat vague installation instructions. Their website didn’t provide a lot more detail. Their customer service did provide a link to video and I ran across a really good one on the internet. Try searching Bora NGX.

Shania Stoltenberg (verified owner) –

This clamp/guide is invaluable for table saw free environments. I couldn’t recommend it enough!

Darby Wehner (verified owner) –

I have used this quite often. The only problem that I had was with the base when I attached my saw I was trying to cut the edge of my countertop which was 1 1/2″. My 7 1/2″ blade wouldn’t cut deep enough to get the whole edge.

Deon McGlynn (verified owner) –

Cuts straight lines and is a great tool. Guide does stick while cutting and adhesive tape starts to peel off when not in use.

Brianne Schmeler (verified owner) –

Worked really well

Autumn Cassin (verified owner) –

Nice product at a decent price.

Freeda Johns (verified owner) –

Worked as described.

Golda O’Kon (verified owner) –

Bought this specifically to cut up plywood safely. The Bora NGX clamp definitely does this. For the price, this is a great little unit. It cuts spot on every time. Like any tool, you have to understand how it works and be aware of a few things to ensure it performs properly. On the NGX clamp, here are some things to keep in mind. Note, these are not in any way flaws. 1.) It does take about 15 minutes to connect your circular saw and dial the settings in to ensure adequate space between the cutting blade and the material. I have a DeWalt DWE575 and dialed it so the clamp is exactly 9/16 from my cut line. 15 minutes is not a lot of time, its easy. Do a few practice cuts. I recommend getting it dialed in to an exact measurement and there are markings on the slide piece to help you do this. Also recommend, clamp the top first, then do the 2 side clamps.2.) In the times I tried to use the right angle guide, it has not performed well. I bought the Premier set mainly because it was the only item available as the other parts (bought separately) were out of stock. In other words, I wouldn’t buy the Premier for this one part.3.) When cutting, be sure to put pressure on the right side of the guide. This ensures there is less blade deflection as you cut. 4.) Some folks complain the clamp down slide gets stuck. The trick is this… The gray handle and the orange edge has to come together in order to slide it. Simple. If it’s not sliding… just push them toward each other, you’ll feel a little click and it slides great.5.) Using the extension piece takes practice to ensure it’s spot on straight once the 4 screws are screwed in tightly. I find that screwing them in a little then pushing both slide components together and then screwing in the screws fully works best. Always check to make sure this is straight, common sense.6.) Some folks have mentioned the plastic construction of the base plate and clamp down. I’m not too worried about this. It’s pretty decent grade plastic. You’ll definitely get a few years out of this tool before anything breaks. If it does, just replace the part. Every tool wears.7.) The instructions… ha, this is one area that could use improvement. However, if you know how to use a circular saw and have actually changed out blades, the setup is pretty self-explainatory. Plus there’s plenty of videos out there.To close, even when I do get a table saw, I will still use the Bora NGX to cut full size plywood down to a more managable size. It is the safest way to do this and watching videos of people doing this on a table saw is pretty funny when you look at their eyes cause they know are uncomfortable.

Shayna Grady (verified owner) –

I have this and the extension for a 104″ reach to rip sheet goods. But buying the two thinking you are going to reconfigure each time you “rip” and “crosscut” a 4×8 sheet is not going to work–too long and too much wear on the parts. It holds well, but takes time to set up straight. A little pricey!

Eleonore Hintz (verified owner) –

This appears to be well-made but I never had to use it after I bought it.

Mose Ryan (verified owner) –

Awesome. I can now cut straight with my circular saw.