BORA Steel 100 in. NGX Clamp Edge Deluxe Set (5-Piece)

$169.96

Deliver a remarkable richness to the outer wall space of your home with the selection of this extra ordinary BORA NGX 5-Piece Clamp Edge Deluxe Set.

In stock

Description

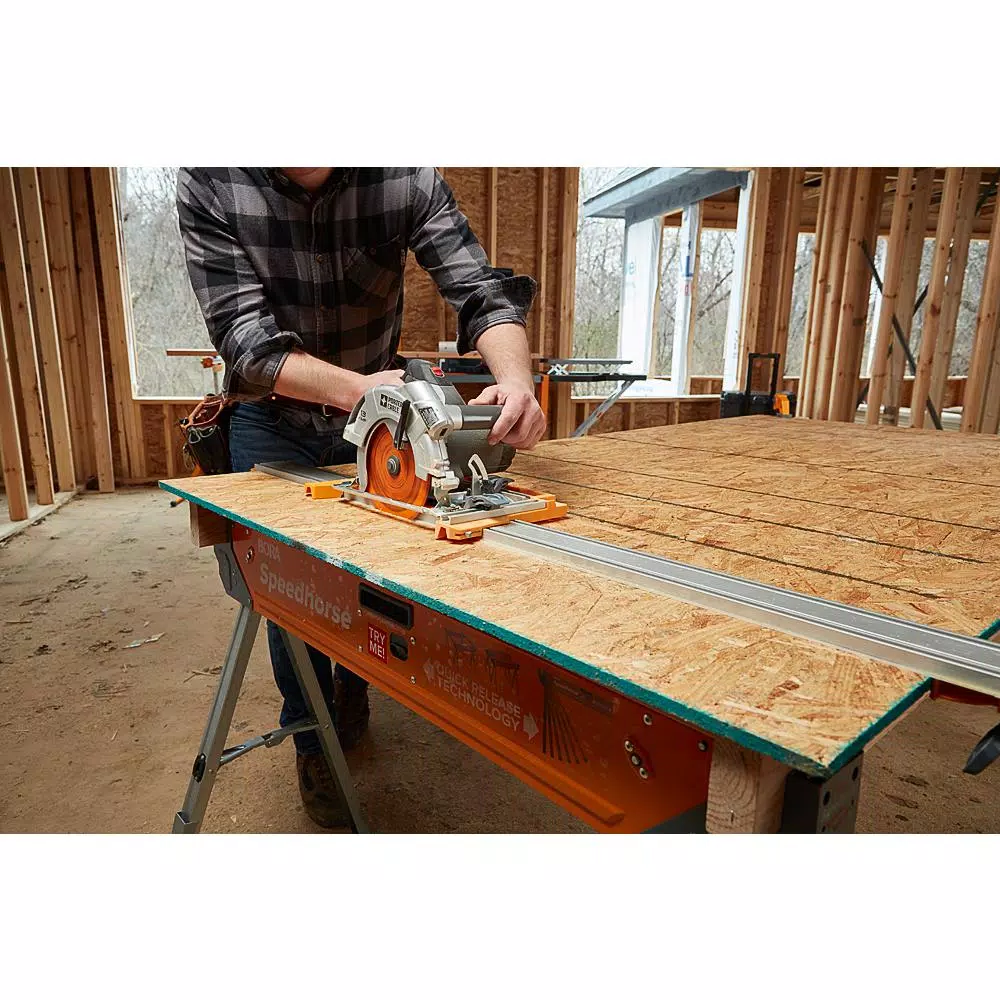

The BORA 5-piece NGX Deluxe Set makes it faster and simpler to break down sheet material and rip boards with clean, accurate cuts every time. This set contains all the pieces and accessories you need to successfully complete any project. Rip material of any size using the Clamp Edge by itself, or with the extension attached. Cut any angle using the Track Clamps. Use the Saw Plate to reduce blade offset and get to work faster, and apply the Non-Chip Strip to your Clamp Edgeto eliminate ugly tear-out. Make every cut easier with this versatile kit.

- Includes: 50 in. NGX clamp edge, 50 in. NGX extension with connectors, pro saw plate, 2 rolls of 55 in. non-chip strip, 2 track clamps

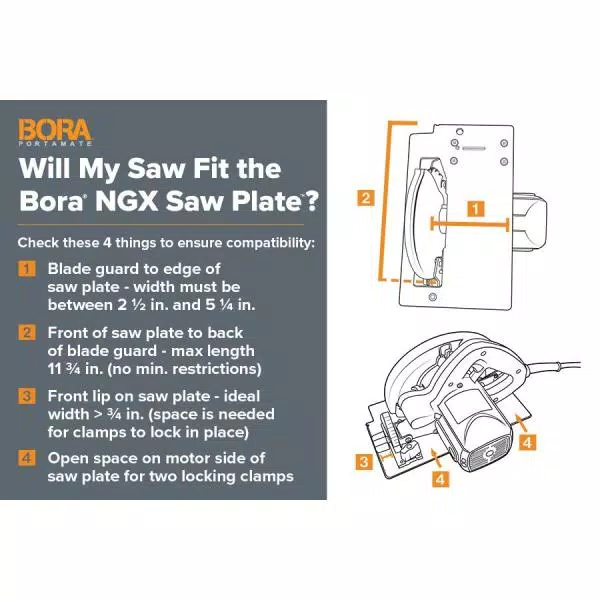

- Saw plate features fixed center molded channel helps reduce blade offset and guesswork

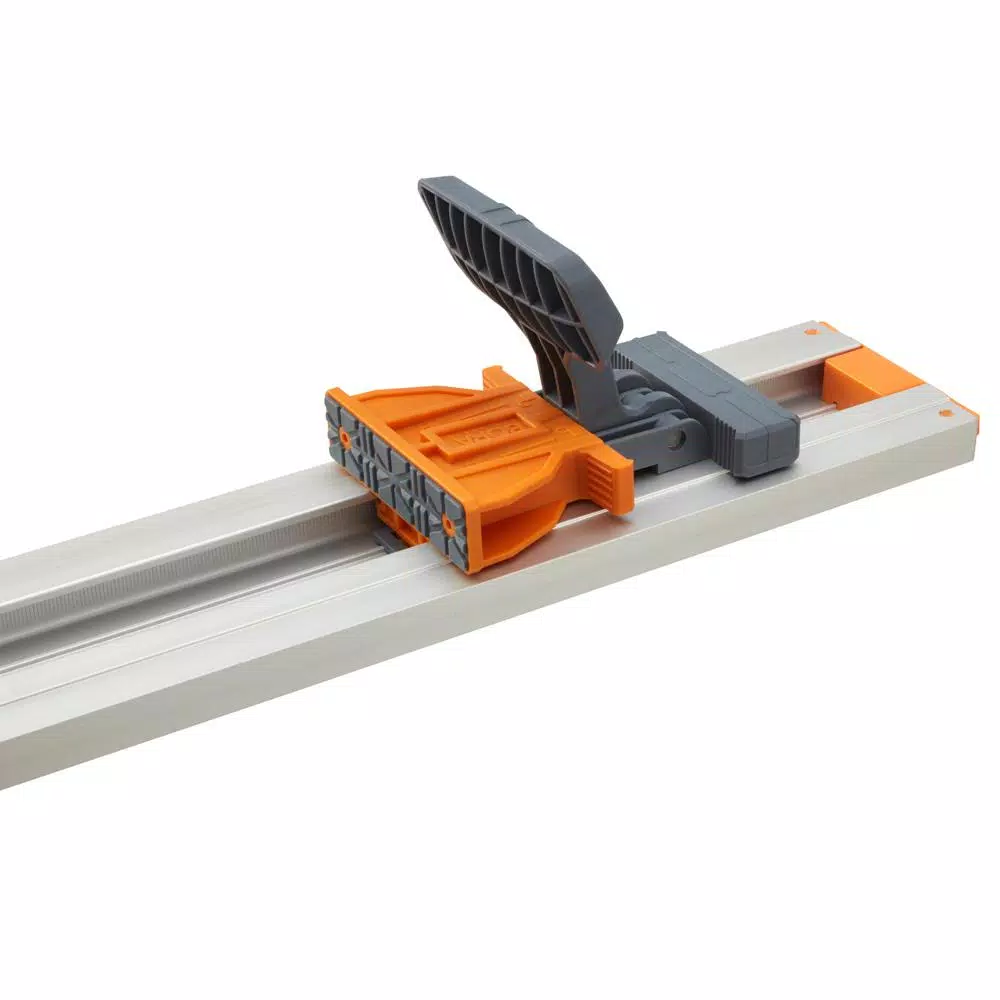

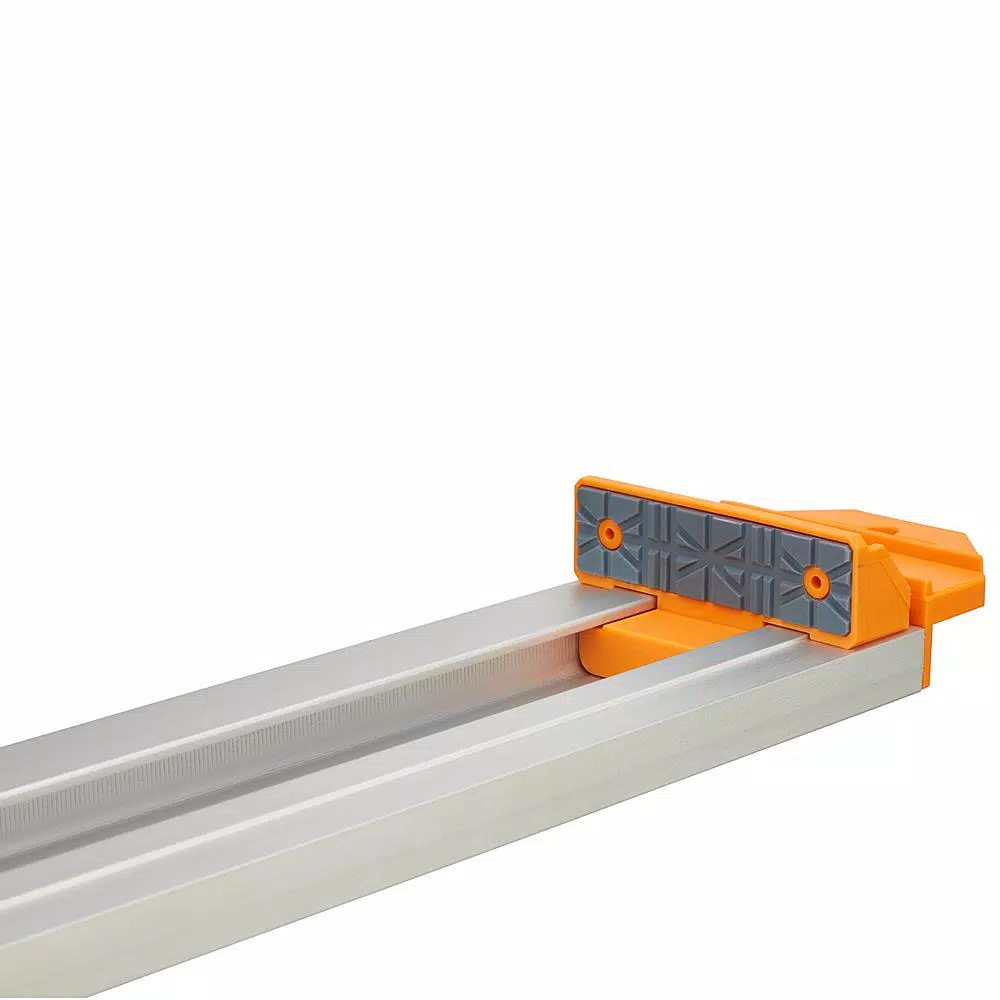

- Track clamps easily attach to clamp edge so you can easily cut any angle

- Clamping end on clamp edge moves with handle for easy adjustability from one side

- Locking handle grabs work surfaces for secure grip that won’t budge

- Pro saw plate and non-chip strips increase accuracy and reduce tear out

- For use with circular saws, routers, jig saws, and other portable power tools

Additional information

| Weight | 25 lbs |

|---|---|

| Dimensions | 10.00 × 3.00 × 63.00 in |

| Clamp Type | Edge |

| Color Family | Silver |

| Hand Tool Type | Clamp |

| Individual/Set | Set |

| Model | 544500 |

| Number of Pieces | 5 |

| Tool Set Type | Clamp/ Vise Sets |

| Tools Product Type | Hand Tool |

Reviews (86)

86 reviews for BORA Steel 100 in. NGX Clamp Edge Deluxe Set (5-Piece)

Only logged in customers who have purchased this product may leave a review.

Related products

Hand Tool Sets

Model# G437Hand Tool Sets

Model# 33Hand Tool Sets

Model# 35202Hand Tool Sets

Klein Tools 7-Piece Assorted Screwdriver Set with Cushion Grip Handles

Model# 85076Hand Tool Sets

Model# 34Hand Tool Sets

Model# 68221Hand Tool Sets

Model# 60-020Hand Tool Sets

Model# 89062

Josh Frami (verified owner) –

Cannot overstate the convenience of the locking mechanizm

Augustus Skiles (verified owner) –

Have you ever had to rip a piece of material and tried to do it with just a steady hand? It’s really hard to get a straight accurate cut. The Bora five piece clamp set with straight edge gives you the ability to get a straight clean cut. You can do four or eight foot material and if the clamp set is difficult to figure out there is a web site available with instructions on the proper use of this handy tool

Andres Daniel (verified owner) –

Precise quick sheet cutting guide. Light, strong, well made and easy to use. Clamping NGX guide and bonus exact fitting saw plate allow time saving cuts. Especially for equal multiple sheet cutting. Clear consise instructions. Initial saw plate set up took a few minutes but once done allowed quick easy detach and reattaching of saw with quick release clamps. Guide clamps to hold securely for use with saw or saw plate. First task was squaring up plywood work surface, guide performed well, easily met expectations. Easy to set perpindicular using square then clamping in place for an accurate cut. The only issue was with the saw plate cut line indicator detaching after use. Likely knocked out. Inserting opposite way, more to my liking in use, care needs to be given when handling saw plate to prevent loss of cut line indicators. Selected the NGX guide for beadboard sheet cutting. Highly satisfied with guides ability to hold panel securely for precise clean cuts. Backing clamp slightly off panel allowed grip without bending for precise clean cuts. Guide quickly proved valuable for accurate quick sheet cutting but also as a straight edge and extension for level adding more value to the economical saw guide. A great DIY tool that performs very well. Highly recommend.

Alda Carroll (verified owner) –

I am reviewing the saw plate, and the 100″ NGX two piece saw guide. Pros1) Easy to set upCons1) The saw plate is plastic. The buckles that hold it to your saw are aluminum, but they are secured to a plastic base.2) The saw guide clamping mechanism is plastic. There’s no way that clamp is going to stand up to years of use 3) It takes quite a bit of force to securely clamp the guide to your work piece, which tends to move the guide a tiny bit from your proposed cut line. You can back off the clamp pressure if you want, but then you risk the guide moving during your cut.4) When mounted on the saw guide, the saw plate rocks a bit from side to side. You can see this on YouTube videos. Since it doesn’t make contact with the wood, it is unstable and will not produce an accurate 90 degree edge5) The saw plate comes with a 55″ cutting strip, but the 100″ guide doesn’t include any strip. So basically, if you want to make clean cuts, you need to spend another $20 for an addition Non-Chip Strip. Not cool Bora!6) The two 50″ cutting guides are made of a thin gauge aluminum. It’s not a problem where cutting is concerned, but just shows how quality took a back seat to profits.Here’s the bottom line;If it came with a 100″ cutting strip, had metal clamps on the guides, and was priced under $100, I’d give it an additional star because the design is kind of cool. As it stands now, it’s an overpriced, over-hyped, novelty item. I returned mine after one use, and decided to make my own with 80/20 aluminum.

John Sanford (verified owner) –

This guide is easy to use for making long crosscuts of plywood. Very light, but held up well as I cut up seven sheets of plywood to build four cabinets

Claude Schulist (verified owner) –

I like the Bora NGX clamp edge but was disappointed that it did not come with a tape to attach to the edge for the saw guide zero clearance cuts. Was very surprised to find that the plastic tape costs over $20.00. I bought this so that I wouldn’t have to separate my existing 50 inch clamp and extension. I only paid $150 for the 50inch clamp, 50inch extension, saw guide, 2-55″ tapes, and 2 clamps. Since I paid $59.94 for the 50″ clamp and will have to pay $20 for the tape guess I should have just bought 2 $149 packages and had a spare tape and saw guide.

Guiseppe Maggio (verified owner) –

Sometimes the cut you want to make is difficult if not impossible on a table saw, especially if you are working alone. With this I can rip a full sheet into workable sections safely and comfortably on sawhorses. Plus if you are like me and can’t cut a straight line to save your life with a circular saw this will do that over and over with minimal effort. The quick clamp system is fast and easy to use on 90 degree cuts and you and attach the tracks with clamps at any angle if you need. Once you set the sled to know the offset of the blade the marks on the sled let you know if you are on your line and ready to cut. It breaks down into a small package and takes little room to store. I would say it is a good alternative to a table saw especially if storage space is at a premium.

Madonna Willms (verified owner) –

Great for cutting sheet goods. The only downside is that it’s not easy to connect & disconnect to the extension.

Shanna Gaylord (verified owner) –

Worked really well

Bella Block (verified owner) –

So glad I have one of these. While I admittedly haven’t used it much, it has been great the handful of times I have put it to use. Cuts now come out perfectly straight, which was always a struggle when simply following a line or using a makeshift guide out of a straight edge and clamps. I also own the saw plate for this guide but wasn’t sure that the blade and edge were parallel nor convinced that the saw would stay firmly in place, so I never actually used it to cut anything. One of these days I’ll give it another shot.Back to the guide:. There’s 50″ between the jaws, so cutting a 4×8 piece of plywood across the shorter side isn’t a problem. Once tightened down, they grip the edges really well – no issues with them coming loose. Now, I’m not sure if this is a design issue or a feature, but once you loosen the clamp, you kind of have to fiddle with it in order to move the jaw. Kind of annoying but not a deal breaker. Another thing that bothers me is the fact that the critical parts (jaws, clamp) are made out of plastic. Should be fine for regular homeowner use, but longevity is a concern. One thing to note is that the clamp sticks out close to 3″ when it is tightened – just something to consider as this may be a problem if you have to set this up on the floor.

Cedrick Schaden (verified owner) –

THis is a much better system than my fist clamp on guide. The clamp on to the board section is mostly aluminum. The saw sled is mostly plastic. My only problem was locating the proper tool to get the sled to fit my circular saw. Once that was sorted out it was smooth sailing. This is much more precise than the early model I had. The light weight will also make this tool very portable. That only leaves me looking at the new battery operated saws.

Rosa Bartoletti (verified owner) –

Excellent guide and easy to use. When the two parts are assembled, they formed a straight edge that was verified with a level. Highly recommended.

Carole McClure (verified owner) –

Perfect for cutting ACM panel on my drafting table

Laila Wyman (verified owner) –

Outstanding way to make smooth straight cuts across sheeting, like plywood, particle board and paneling. The saw plate is well designed to accommodate many different manufacturers circular saws. I was easily able to attach the 2 saws that I have. The saw plate slides along the saw tracks to provide for easily sawing sheeting. The first section of track is long enough to fit across up to 50″. The second section of track fits on the end of the first to extend the length of cut to 100″. 4 screws are used to attach the 2 sections together. The tracks are made from rigid aluminum and the saw plate is made of plastic. even though it was made of plastic it was durable, rigid and held my 2 saws tightly in place. The only negative I found was somewhat vague installation instructions. Their website didn’t provide a lot more detail. Their customer service did provide a link to video and I ran across a really good one on the internet. Try searching Bora NGX.

Nikko Gerhold (verified owner) –

This NGX Saw Plate can be great but it does not fit my Milwaukee M18 circular saw and the directions are complicated. The plate will hold the vast majority of circular saws though and glides across the BORA NGX Saw Edge systems. The problem with my M18 circular saw is that its bottom plate is not a rectangle, the back inside end does not have a corner for the clamp to attach nor can I ensure that my saw is perfectly square on the ruler marks of the NGX plate (see pictures). The directions are complicated. First, I put the no-chip strip in the wrong spot. The directions say to put it on the edge of the NGX Edge saw guide but didn’t specify underneath the Edge. I tried to remove the strip but the adhesive came off too and it was a mess. Second, its fairly easy in theory to mount a saw on the plate but the directions make it difficult. I found myself wondering what the heck an “excrusion” is. The illustrations could be much better. This plate is well-engineered and sturdy. Using this plate, it is much easier to get an accurate cut because the no chip strip tells you where the blade will cut as opposed to not using the saw plate and measuring the distance from your circular saw’s blade to the edge of the edge clamp. I still use my NGX Edge saw guide as its a great substitute for lugging big boards across a table saw. The saw must be mounted perfectly on this plate for smooth and clean cuts. Made in China.

Nona Hansen (verified owner) –

Bought this specifically to cut up plywood safely. The Bora NGX clamp definitely does this. For the price, this is a great little unit. It cuts spot on every time. Like any tool, you have to understand how it works and be aware of a few things to ensure it performs properly. On the NGX clamp, here are some things to keep in mind. Note, these are not in any way flaws. 1.) It does take about 15 minutes to connect your circular saw and dial the settings in to ensure adequate space between the cutting blade and the material. I have a DeWalt DWE575 and dialed it so the clamp is exactly 9/16 from my cut line. 15 minutes is not a lot of time, its easy. Do a few practice cuts. I recommend getting it dialed in to an exact measurement and there are markings on the slide piece to help you do this. Also recommend, clamp the top first, then do the 2 side clamps.2.) In the times I tried to use the right angle guide, it has not performed well. I bought the Premier set mainly because it was the only item available as the other parts (bought separately) were out of stock. In other words, I wouldn’t buy the Premier for this one part.3.) When cutting, be sure to put pressure on the right side of the guide. This ensures there is less blade deflection as you cut. 4.) Some folks complain the clamp down slide gets stuck. The trick is this… The gray handle and the orange edge has to come together in order to slide it. Simple. If it’s not sliding… just push them toward each other, you’ll feel a little click and it slides great.5.) Using the extension piece takes practice to ensure it’s spot on straight once the 4 screws are screwed in tightly. I find that screwing them in a little then pushing both slide components together and then screwing in the screws fully works best. Always check to make sure this is straight, common sense.6.) Some folks have mentioned the plastic construction of the base plate and clamp down. I’m not too worried about this. It’s pretty decent grade plastic. You’ll definitely get a few years out of this tool before anything breaks. If it does, just replace the part. Every tool wears.7.) The instructions… ha, this is one area that could use improvement. However, if you know how to use a circular saw and have actually changed out blades, the setup is pretty self-explainatory. Plus there’s plenty of videos out there.To close, even when I do get a table saw, I will still use the Bora NGX to cut full size plywood down to a more managable size. It is the safest way to do this and watching videos of people doing this on a table saw is pretty funny when you look at their eyes cause they know are uncomfortable.

Glen Crist (verified owner) –

BORA NGX Clamp Edge Saw Guide is a quality guide for circular saws, routers and even jig saws. It is made of heavy duty aluminum with an excellent clamping method that secures the guide rail above on top of the sheet goods with an edge clamp. The handle to tighten the guide is easy to use by one person and doesn’t budge at all when used with the saw. A secure fit is critical in preventing the saw from wandering off the cut. It doesn’t happen often, but it can ruin the cut and I’ve done it. I had a shorter Rockwell guide and it wasn’t nearly as well done as this one. There is an optional second section that can be joined to this 50-inch rail extending it to handle rip cut for sheet length goods, too.An advantage of this system is the excellent options that can be had, sold separately, to make it even better to use. I used my rail with their universal circular saw plate that mounts the circular saw using hold down clamps. The plate can then be slipped into the slots on the top of the aluminum rail securing it. It then works more closer to a track saw. Included with the plate is a length of 3M non-chip strip to attach to the bottom of the plate along the saw blade, reduces any top edge tear-out for a cleaner cut. This is useful for bonded veneers. Bora has similar plates for routers and a jig saws that slip into the slots on the top of the rail. Finally, I was at initially concerned about the plate being plastic. It is thick plastic and feels substantial for DIY work, all well done. I tried the rail and saw plate out with my Milwaukee cordless circular saw and it fit nicely after about five minutes of making set-up adjustments. You have to slide over the hold down rail that has two clamps and make it exactly parallel to the saw blade and lined up on the plate’s blade guide. It is all easily done with allen screws and a flat slotted screwdriver. Really not a big deal, but the saw has to be accurately lined up to get a straight cut. I didn’t use their non-chip tape and didn’t need it for the MDF used. Overall, this is an excellent tool for crosscutting sheet goods. The rail alone is first rate and with the circular saw plate it goes quicker and is more accurate. I also own a small work-site table saw and when working alone prefer this method to cut sheet goods on two saw horses. It just is safer with my experience level and equipment setup. I feel the Bora system however you’ve configured it is a good value for DIY-ers to other methods.

Benedict Bashirian (verified owner) –

This is a very convenient tool for cutting across large sheets, like plywood. Being 50″ wide means being able to handle 4′ sheets of plywood. Having a self locking feature is another nice feature. Simply line up on your marks, lock it into place and cut.

Eldred Senger (verified owner) –

It works but very time consuming checking and double checking that the saw is aligned correctly as well as the saw offset is correct for the cutting once aligned with the guide. The buckles aren’t as robust as i’d hope they’d be and are too flexible to be able to hold the saw in place without movement. one of my buckles wasn’t completely assembled as it was missing a pin for the closure. luckily i was able to get a nail to fit for the purpose. I’m happy with the product and i feel it provided me with straight cuts. it just takes a long time for set up.

Zella Hammes (verified owner) –

Making precise cuts on sheet goods has always been a problem. As a hobbyist who makes a lot of furniture and cabinetry, I usually do precision cuts on the table saw. But making precision cuts on sheet goods has always been a problem. In the past I would calculate the offset and clamp a board to the plywood and hope that the board was straight and square. My norm was to cut oversize and then do the precision on the table saw, but that was not always possible. A track saw would do a much better job, but I could not justify the expense. When I got the BORA 50” NGX Clamp Edge I found I no longer had to rely on the accuracy of whatever board I happened to find. This clamp adjusts quickly and is automatically square with the surface. It holds tightly and cures most of the difficulty I had. By adding the NGX Pro Saw Plate, it allows me to use my circular saw like a track saw. Now I can rip through sheet goods precisely without calculating the offset and with the non-chip strip attached to the clamp, tear out is greatly reduced. The circular saw attaches quickly and securely to the Saw Plate with 3 locking hold downs. Once I found the proper Allen wrench, setup was easy and I was ready to saw. (Hint – it is 3mm.) Very happy with this combination and it will definitely save me a lot of time and material.