BORA Steel 31 in. Parallel Clamp (Set of 2)

$96.03

Grab an extraordinary addition to modernize your workshop without any hesitation with the assistance of this BORA Parallel Clamp.

In stock

Description

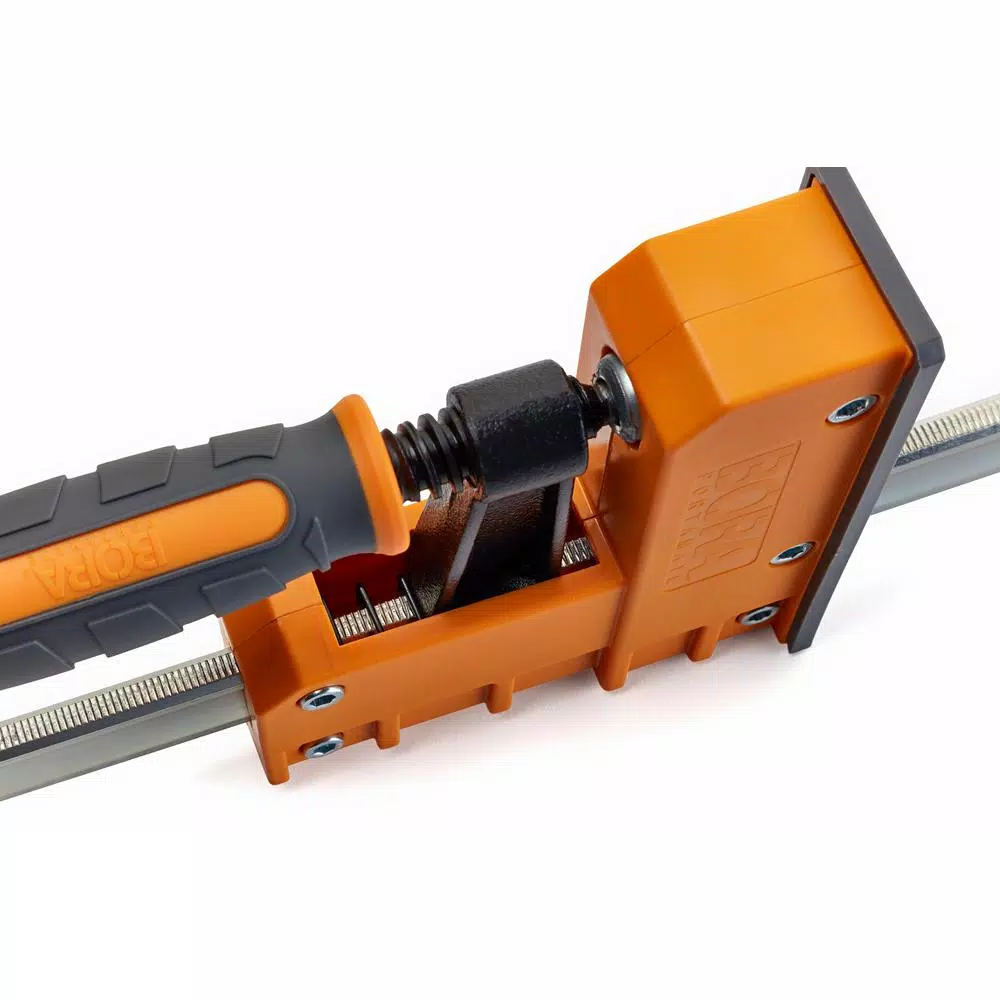

BORA knows exactly how important it is to rigidly clamp down your case goods and other woodworking projects. Rock-solid stability means more precise work, and a superior finished product that simply radiates expert craftsmanship and pride. Our Parallel jaw clamp is the woodworking clamp that both enthusiasts and professionals reach for when working on their projects. The reasons why are simple: this is a truly superior woodworking clamp. With the perfect amount of pressure (1100 lbs./500 kg), a three 89 mm throat with padded jaw, and sizes that range from 12 to 50, it becomes an extremely versatile tool for your clamping needs. Add in the little extras that make all BORA products stand out in this case, a passive lock bottom jaw, and large, easy-grip handle. Its almost like you designed this clamp yourself (indeed, we asked woodworkers what they wanted, then built it). Get 1 (or several) for your shop today.

- Grip it right, clamp it strong, case goods and other woodworking projects require precision clamping, that’s where this 31 in. (787 mm) parallel jaw clamp earns it’s keep

- Our design keeps the jaw in place while winding the clamp

- Not too loose, not too tight – just right (1100 lbs./500 kg of clamping pressure)

- Available in several sizes this BORA parallel jaw clamp comes in several different sizes, ensuring no project goes unclamped

- Top BORA quality, BORA knows how important rock-solid clamping is to woodworkers, this parallel clamp is an exceptional woodworking clamp from the woodshop experts

- 3-1/2 in. throat

- Item net weight: 7 lbs.

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 14 lbs |

|---|---|

| Dimensions | 38.50 × 5.50 × 2.50 in |

| Clamp Type | Parallel |

| Color Family | Orange |

| Hand Tool Type | Clamp |

| Individual/Set | Set |

| Model | 571131T |

| Number of Pieces | 2 |

| Tool Set Type | Clamp/ Vise Sets |

| Tools Product Type | Hand Tool |

Reviews (6)

6 reviews for BORA Steel 31 in. Parallel Clamp (Set of 2)

Only logged in customers who have purchased this product may leave a review.

Related products

Hand Tool Sets

Klein Tools 7-Piece Assorted Screwdriver Set with Cushion Grip Handles

Model# 85076Hand Tool Sets

Model# 63518Hand Tool Sets

Model# 90402Hand Tool Sets

Model# 437-0Hand Tool Sets

Model# 35202Hand Tool Sets

Model# 34Hand Tool Sets

Model# 436-0Hand Tool Sets

Model# 89032

Emely Stark (verified owner) –

Wow, I absolutely love these clamps by Bora. The passive lock design is a nice feature that allows you to square up the clamp…then just twist the screw portion to tighten everything up. The face of the clampis wide and non-marring with a nice rubber grip pad. I recently used these clamps to make a picture frame and keep everything square as the glue dried. The clamps are easy to disengage as well. I absolutely love these and I highly recommend for the professional or DIY enthusiast

Lessie Mante (verified owner) –

These clamps are very heavy, duty. They are relatively easy to operate, once you know how to. To open the clamps, pull the twist handle away from the steel shaft and then it slides easily either direction. Instructions would be helpful.The clamping pads look off when slid together, but the pads come together evenly when the screw handle is tightened to apply even pressure along the clamp surface.One clamp arrived with the steel shaft discolored. Not sure why, but it can be seen in the photos below. It could just be a slight defect, or something else.

Carley Dibbert (verified owner) –

Picked up a pair of 31 in Parallel Clamps, Bora Portamate, for a furniture repair project. I have numerous similar appearing clamps, but I needed more grip spread over a larger area. These parallel clamps fill the bill. These clamps bring a new meaning to the phrase “heavy duty”! They are large, heavy, and clamp very well. At first glance the clamping areas were not parallel and I was worried about too much pressure in a very small area. But the clamp flexes to become parallel without flexing any further. Lift up on the pressure screw handle and slide the clamp jaws either closer or farther apart. There is a plastic stop bar at the end of the clamping bar that is adjustable for making repetitive clamp uses at the same width very easy. 1100 lb clamping pressure, 3.5 in throat depth, and best of all Lifetime Warranty! What a great find!

Hobart Lehner (verified owner) –

These clamps are made to work well. There is absolutely no wiggle when they are clamped down so they are excellent for furniture and cabinet building. There is a non-marring coating to protect your project and at 31″ these will be very useful in most applications. They are a bit hard to open when first used but I think that will improve with time. Overall a very good clamp.

Connie Kovacek (verified owner) –

This is the first set of parallel clamps I’ve owned. I like the square bases that allow the clamps to stand on their own,and the replaceable jaw faces that allow for non marring clamp pressure. The headstock is easy to rotate to use as a spreader clamp. Since there were absolutely no instructions with the clamps, it took a bit to figure out how to slide the head back and forth on the bar. It is the first clamp I’ve had that the screw handle pushes down toward the bar to release from the teeth on the bar. Either a printed or web based instructional would be very helpful.

Addison Ernser (verified owner) –

These clamps will be a go-to item for the woodworking crowd (unfortunately, the plastic parts will preclude their use in welding fit up), with the acme-threaded lead-screw providing true parallel jaw movement to facilitate glue-up. The integral bar maintains the alignment of the fixed and moveable jaws, while the plastic end retainer serves to keep the clamp “on the level” when resting on the work surface. The retainer incorporates a cam-type locking mechanism to secure it to the desired location on the bar. Care should be taken when securing the end retainer to avoid over torquing the securing knob (hopefully replacement parts are available, though nothing was found on the manufacturer’s website). The jaws have removable faces which are resistant to glue. Again, nothing was noted regarding replacement parts, but these faces will, no doubt, at some point have to be replaced. The clamps can be used utilizing the full 3 ½ inch x 1 ¾ inch face or, if orientation requires, the ¾ inch “side” face (with the bar abutting the work piece). After using, for years, clamps using a section of pipe as the backbone element, the major improvement of this style of clamp, not having to concern oneself with the rotation of the jaws, is apparent. An additional plus is the one-handed operation (lifting up on the handle allows one to slide the jaw) to adjust the movable jaw and then snug it down, using the acme-threaded leadscrew (one will probably want to use some dry lubricant on the threads). The 31 inch bar will handle most general clamping needs in the home shop (as well as the commercial ones). The manufacturer’s specification indicate the clamp is capable of applying 1100 pounds…(which, for the 6.125 square inch jaws results in about 180 pounds per square inch) sufficient for most glue ups. The moveable jaw can be reversed, if it is necessary to apply spreading pressure. The handle has a softer durometer insert material to provide comfort while applying pressure to the work piece. There is no provision for auxiliary torque input (square shaft or hex insert), however, it was possible to apply the necessary amount of clamping pressure unaided. The manufacturer offers a lifetime warranty should any defects manifest themselves. Their ruggedness was proven by virtue of suffering no damage to the clamps, even though the shipping damage to the carton was significant (see photo).If a ready source of replacement jaw inserts as well as intermediate stand-offs (to keep the workpiece off of the bar) was available, a fifth star would be deserved.