BORA 17 in. x 48 in. Universal Mobile Base

$58.86

The PORTAMATE Portamate Universal Mobile Base 14 in. to 43 in. features side rails and corner pieces with holes spaced. It is ideal to move band saws, table saws, sanders, drill presses, jointers and planers. It holds machines up to 400 pounds.

In stock

Description

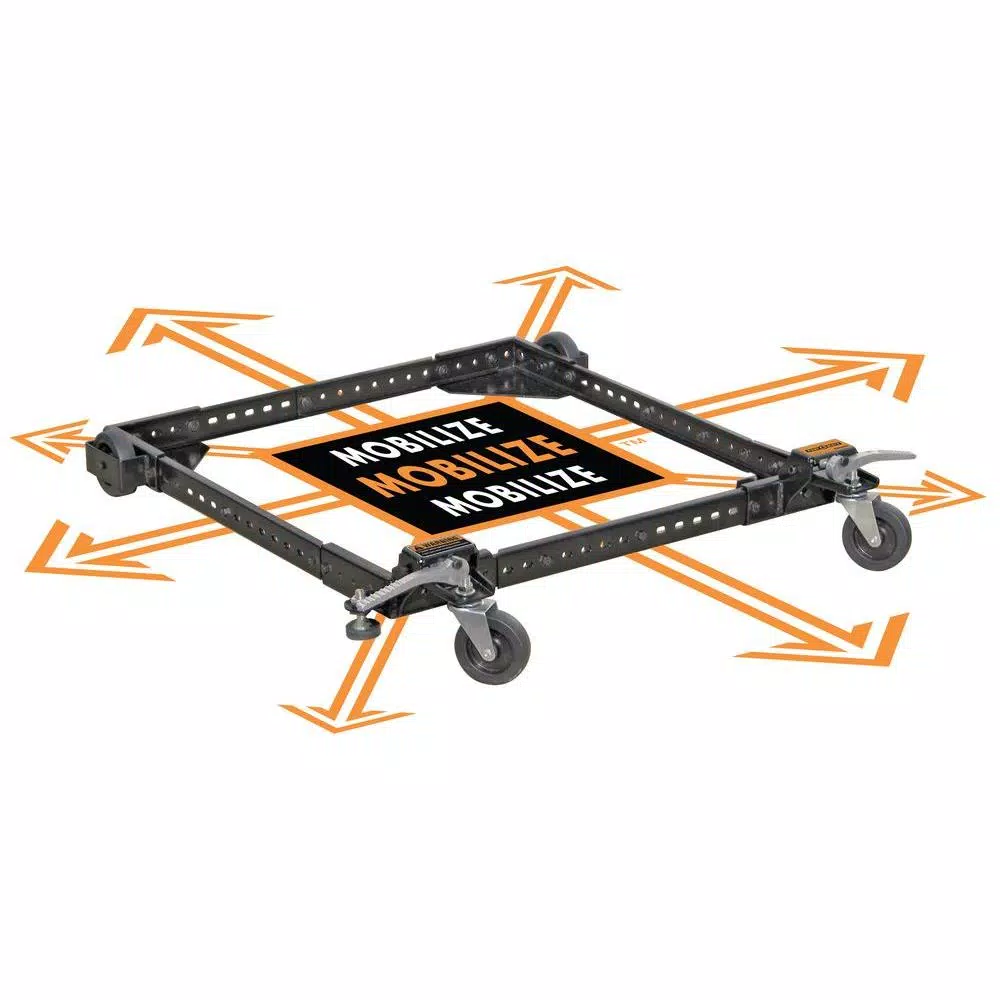

With the PORTAMATE PM-1000 adjustable mobile base, size is no longer an issue. Fully adjustable mobile base features side rails and corner pieces with holes spaced every 1 in. to ensure the perfect fit for your machine. Move band saws, table saws, sanders, drill presses, jointers, planers and much more. Holds machines up to 400 lbs.

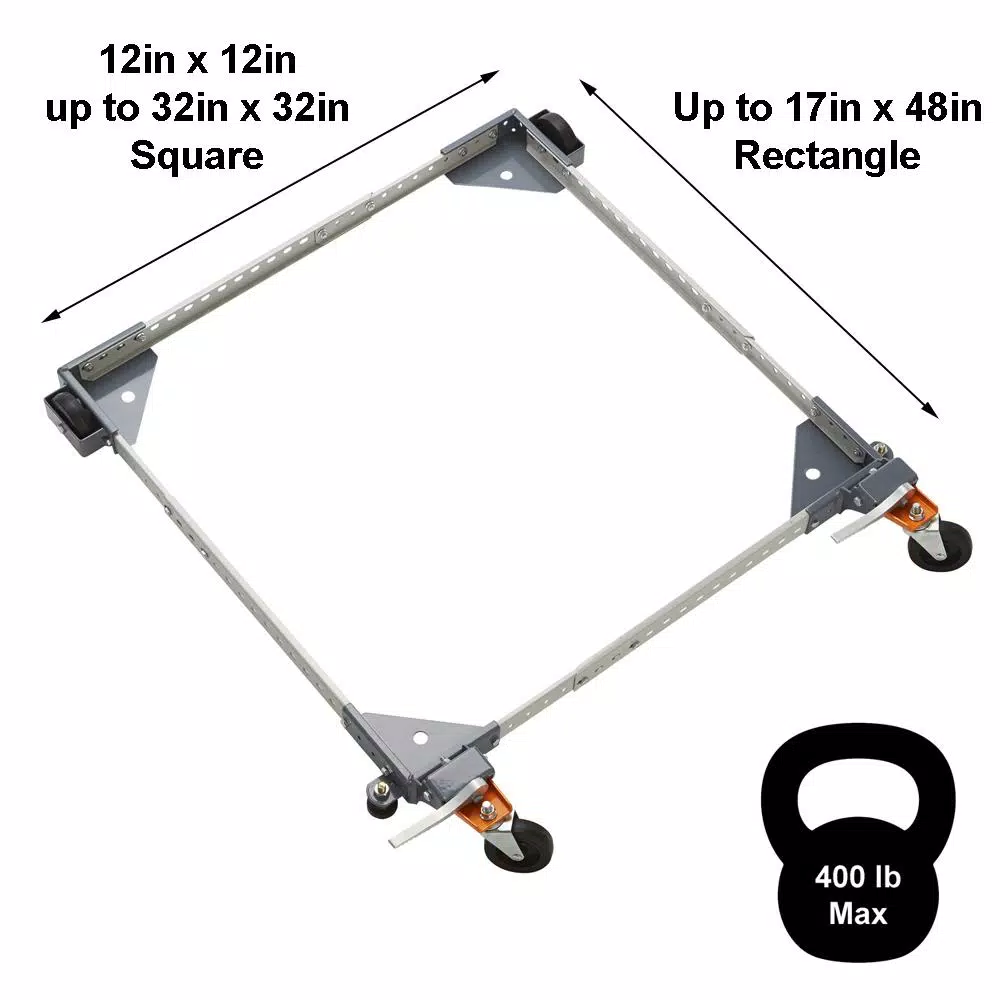

- Each side expands from 17 in. to 48 in.

- Maximum square 32 in. by 32 in. maximum and a minimum size 12 in. x 12 in.

- Adjusts in 1 in. increments – all parts included

- (4) 3 in. Dia wheels with floor locks

- Move your tools anywhere with ease

- 2-point rubber leveling feet

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 11 lbs |

|---|---|

| Dimensions | 4.00 × 19.00 × 7.00 in |

| Color Family | Orange |

| Model | PM-1000 |

| Power Tool Accessory Type | Other Accessory |

| Table Height (in.) | 1.57 |

| Table Length (in.) | 48 |

| Table Width (in.) | 17 |

| Tool Stand Features | Universal, With Wheels |

| Tool Stand Type | Table Saw Stand |

| Tools Product Type | Power Tool |

Reviews (38)

38 reviews for BORA 17 in. x 48 in. Universal Mobile Base

Only logged in customers who have purchased this product may leave a review.

Related products

Tool Stands

Model# 194093-8Tool Stands

DEWALT 29.8 lbs. Compact Miter Saw Stand with 500 lbs. Capacity

Model# DWX724Tool Stands

DEWALT 32-1/2 in. x 60 in. Rolling Miter Saw Stand with 300 lbs. Capacity

Model# DWX726Tool Stands

Bosch Portable 10 in. Table Saw Folding Stand Compatible with GTS1031

Model# GTA500Tool Stands

Model# DW7440RSTool Stands

DEWALT 29 lbs. Heavy Duty Miter Saw Stand with 500 lbs. Capacity

Model# DWX723Tool Stands

Model# RK9002Tool Stands

DEWALT 15.4 lbs. Heavy Duty Work Stand with Miter Saw Mounting Brackets

Model# DWX725B

Chloe Oberbrunner (verified owner) –

Easy to assemble. Table saw moves with ease (even with one hand after shoulder surgery).

Adriel Sipes (verified owner) –

I purchased 5 of these bases and they were not hard to assemble. They work as they should. I will buy more if I need them. Two of my purchase were the heavy duty bases, they are good also.

Marjorie Dietrich (verified owner) –

This is very solid and the wheels kick up so easily. Very happy with my purchase.

Tara Mann (verified owner) –

I needed mt table saw to be portable to be useful. This helped meet that…

Eliseo O’Reilly (verified owner) –

I fortunately had one of these my brother gave me from a sale he had gone to. I like it better than those offered from Grizzly made by Shop Fox, and its a little cheaper. The way it operates is better and easier to use. I now have three of these and would recommend them for equipment you would like to move occasionally I have one on a shaper, one on a table saw, and another on a router table.

Leila Schinner (verified owner) –

It fit my Rigid 6 “ Jointer very well. Rolled the heavy Jointer with ease. I am very pleased with the Portamate quality.

Darius Rosenbaum (verified owner) –

had purchased one a few years ago and have been very pleased with it, bought 2 more for other machines, love the mobility they give.

Johnpaul Rutherford (verified owner) –

not heavy duty.It did not hold up to well.

Aubrey Rolfson (verified owner) –

A solid base that I am using for my table saw. Overall a very good product. My only complaint is the poorly-written instructions, which also includes a very bad (and tiny) assembly diagram….pretty much useless. I ended up assembling the base with just some common sense, and it worked fine.

Julianne Krajcik (verified owner) –

Very good and sturdy. However, certain rectangle sizes will no be accommodated by whats in the box. The size I needed was 18″ X 36″, and I needed to buy the extension kit. Still not sorry I bot this product. very functional.

Derek Cruickshank (verified owner) –

The mobile base seems to hold my bandsaw well, but the lifting mechanism is very poor. I have to lift/tilt the machine in order to get the mobile base to lift so that the machine can be moved. If I had to do it all over again, I would purchase the dedicated base made by the bandsaw manufacturer.

Karl Mraz (verified owner) –

These are great for in the shop. I now have 4 of them and they allow me to move equipment in and out of position when I need to use it. They are easy to assemble and can be customized for the stand you are using and easy to move when needed and stable when using the equipment. I recommend them for the shop.

Salma Satterfield (verified owner) –

I own a least of 1 of 5 different brands of mobile bases and this one is my favorite. Easily assembled with good size versatility and quality materials. I bought this one for a 6″ Jet joiner (250 lbs) and it works very well. The wheel activation levers are strong aluminum, not plastic. The wheels are close in to the frame so that you are not tripping over them when working closely. I would buy this again if needed.

Matilda Schoen (verified owner) –

I was in the market for mobile bases for my table saw and my floor drill press. After reading the reviews I decided to order the PortAMate PM1000 with a 400-pound capacity. Several days later, I had an opportunity to order a WEN MB-500 with a 500-pound capacity base and decided to compare the two side-by-side. They are priced the same and arrived the same day. They both can accommodate the same tool foot-print. I suspected that the WEN model was going to be a heavier duty model based on the weight of the package alone. The design of the two models is basically the same except for the WEN’s larger and heavier gauge steel corners and their respective lifting mechanisms.The side rails are the same sizes and look like they could be interchanged. The PortAMate has black-plated hardware which blends in with the color of the base; the WEN has bright-plated hardware. Both use serrated washer head nuts which allows the fastener to be tightened with a wrench or socket from one side. The fasteners are all metric sizes. And both units took 45 minutes to assemble. After assembling the PortAMate and loading my table saw on it by myself using blocks and prybars, it was clear that I would not be able to remove it by myself. In order to swap bases, I placed the base corners on 2X’s and removed the bolts from the opposite side rails, so I could slide the corners out from under the tool’s legs. This approach worked fine. In fact, the WEN instructions recommend assembling the base with the tool sitting on 2X’s to avoid having to lift the entire tool at the same time onto the base. Good idea. So, I used the WEN approach to get the WEN base under the table saw. Although both bases have holes on 1-inch centers, the holes in one of the mating side bars are slotted which provides additional adjustability to provide for a tighter fit. With the bolts hand tightened, I used a bar clamp to pull the sides of the base together so the side rails could be pulled in for a snug fit to the tool legs. Then I tightened the bolts.With the bases in the lifted position, the maneuverability of both was equal. Both have the same diameter rear wheels—3-inches. PortAMate has 2.875-inch caster wheels while WEN’s are 2.375-inches. The PortAMate caster wheel has a riveted in place axel while the WEN has a larger bolted axle making it replacable.The cam lifting design is the second main difference between the two models. • On the PortAMate, the “actuator cam” is an aluminum extrusion section. It can be installed with the lever facing inboard or out. The cam bears down on the caster “swivel plate” to lift the base off the floor. The swivel plates come with a small amount of pre-applied grease applied at the point of cam contact. There is no mention of the lubricant in the instructions so look for it when you unpackage the swivel plates. The design relies on the aluminum cam rolling over a painted surface. The cam lever moves sideways to the base; the cam action does create a positive down-lock that can be released with your toe. When the cam lever is up, it is free to flop back and forth. The cam appears to be a weak link in that the pivot hole is not “captured” at the top. Not sure why they would do this from a structural standpoint.• On the WEN base, the cam action is more like the step-on lever action found on more expensive bases. The “foot lever” includes the cam that pushes down on the “swivel plate.” The contact surfaces are both painted which I believe initially led to one of the foot levers releasing while the machine was being moved. After cycling the foot lever a few times—and removing some of the slippery paint(?)—it seems to stay locked down. The toe release force is much less than the PortAMate model.The third difference is the warranty—one year for the PortAMate, two years for the WEN. The fourth difference is in the owner’s manuals—WEN’s is much better, with larger diagrams and photos. The PortAMate manual has one diagram that is very small and difficult to read. Both could use improvement but once you have assembled one base, it is very easy to do a second one even without a manual.The WEN base is staying on the table saw. I prefer the step-on lever and easy toe release, the longer warranty and the larger weight capacity, all for the same price. The PortAMate is going on the drill press which I do not need to move as often. The PortAMate manual did have a good recommendation for using their base (or any base) on narrow base tools such as band saws and drill presses (with high CG’s): Install the swivel wheels on the side of the base to increase the effective width of the base by about 7-inches overall. The WEN base could be configured in the same manner but would increase the overall width by 13-inches if space is an issue. Both are very economical products, and both leave me with a couple of lingering questions. So…which base will I order for my bandsaw?

Sabina Shanahan (verified owner) –

Because I have limited space in my home wood shop, I have put five of my stationary power tools on mobile bases. In the process I have tried several different brands and styles. This is the one that has worked best for me. The floor in my shop is flat but not perfectly even and some of the mobile bases do not lift high enough to clear the very small irregularities or occasional wood chip, so they hang up when I’m trying to move the tool. The Portamate has enough clearance to roll easily around the shop as needed but still remain stable. The foot operated lift levers (cam levers) are in pairs – a left and a right and they can be installed either way. Installed one way, the lever will be sticking out where you can catch your foot on it every time you walk by. Installed the other way it will only stick out when you have lifted the tool to move it, and will be out of the way once you have set the tool down to use it. One factor that might be a consideration for some users is the size of tool stand that will fit on the Portamate mobile base. The base of my oscillating drum sander fits, but barely. If my tool stand was even one inch wider it would not have fit. However there is an extension kit available (extra cost) that would allow it to fit much larger tool stands.

Eloisa Beier (verified owner) –

I got one for my table saw and it worked so good I just ordered one for my radial arm saw. I plan on getting one for all my tools on flood stands. I wanted to see how stable the saw was when it was not in the rolling mode. My table saw was like it was sitting on the flood with out portamate, very stable!!! If you have a small shop and have to move you tools every time you want to use them this is the accessory that is a must.

Felicia Ziemann (verified owner) –

I have my band saw on this base. This base only raises the saw about an inch off the ground which is crucial for a heavy tool with a high center of gravity which is inherently unstable. Assembly was straight forward. Best value in mobile base.

Stephania Herman (verified owner) –

Lift lever cams are a little aggressive otherwise it’s great.

Luther Dare (verified owner) –

Just like the picture. Works well on my table saw, stable and allows me to move it out of the way when not in use. Only complaint was the instructions are poorly written. That should not be a problem for the customer that would buy this type of product. Made in china.

Hannah Legros (verified owner) –

Easy to assemble, works great, solid construction, instructions easy to follow