BORA NGX 100 in. Clamp Edge

$109.00

Break down sheet material rip and crosscut boards with clean, accurate cuts every time by choosing this affordable BORA NGX Clamp Edge Offers durability.

In stock

Description

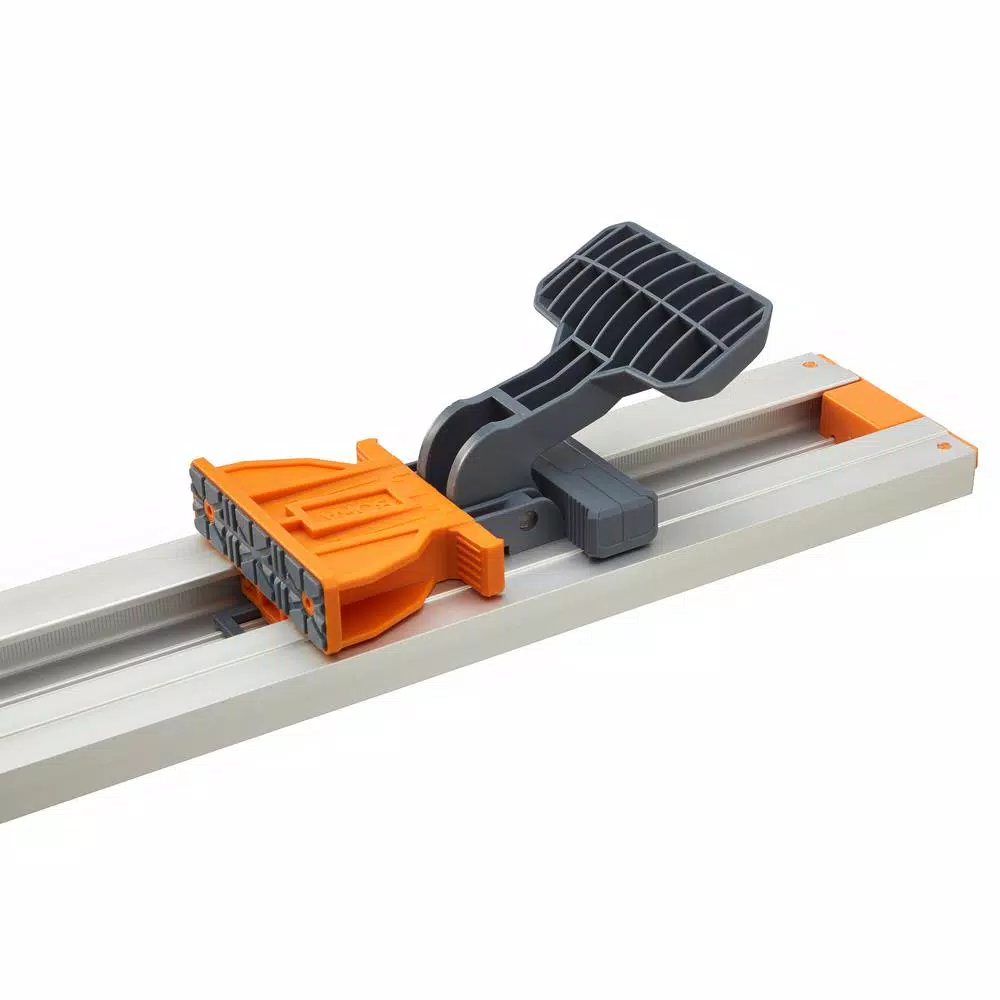

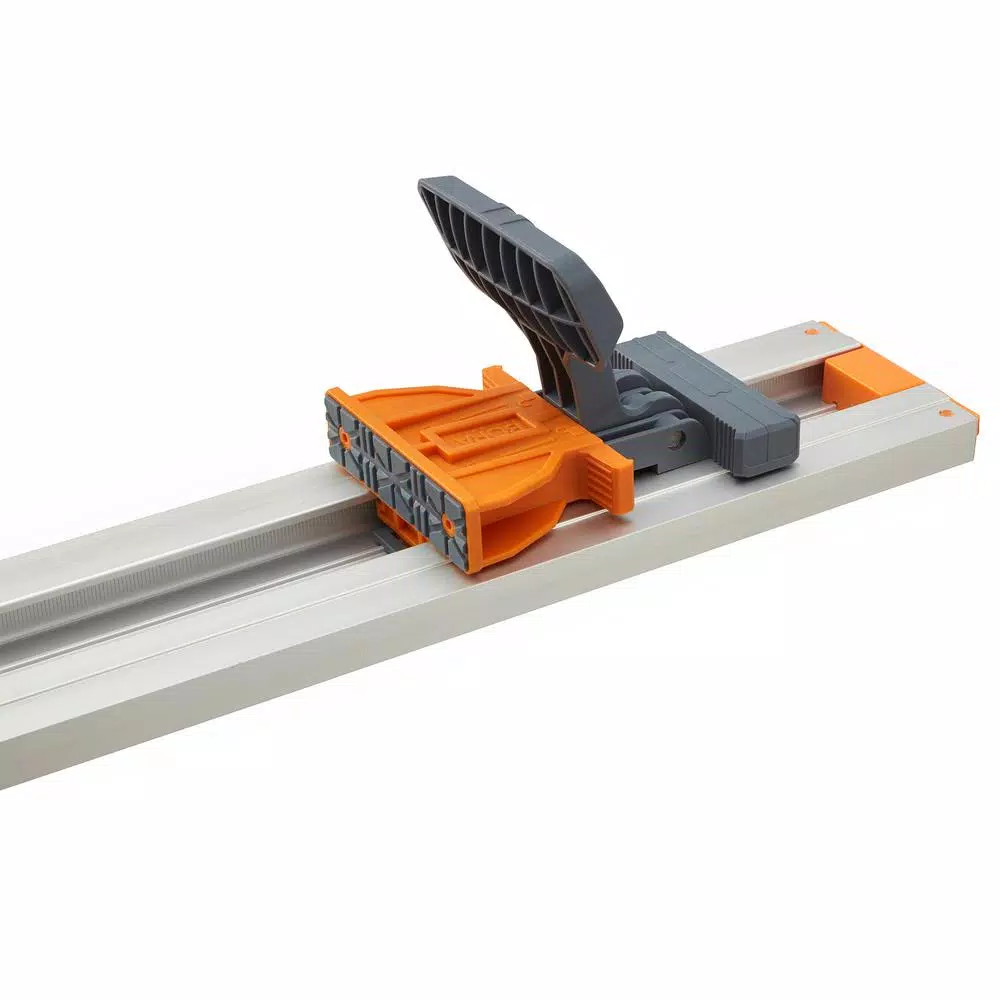

The NGX Clamp Edge System makes it faster and simpler to break down sheet material rip and crosscut boards with clean, accurate cuts every time. NGX gives you track saw-like precision without the hefty price tag. Its never been easier to rip, cut, and break down material than with the all-new NGX Clamp Edge System. No more fumbling with adjustable clamp ends on opposite sides of the straight edge the adjustable clamp is connected to the handle. Simply hook the Clamp Edge across your board, line it up with your cut, and clamp it down all without moving your feet.

- Clamping end moves with handle for easy adjustability from 1-side

- Locking handle grabs work surfaces for a secure grip that wont budge

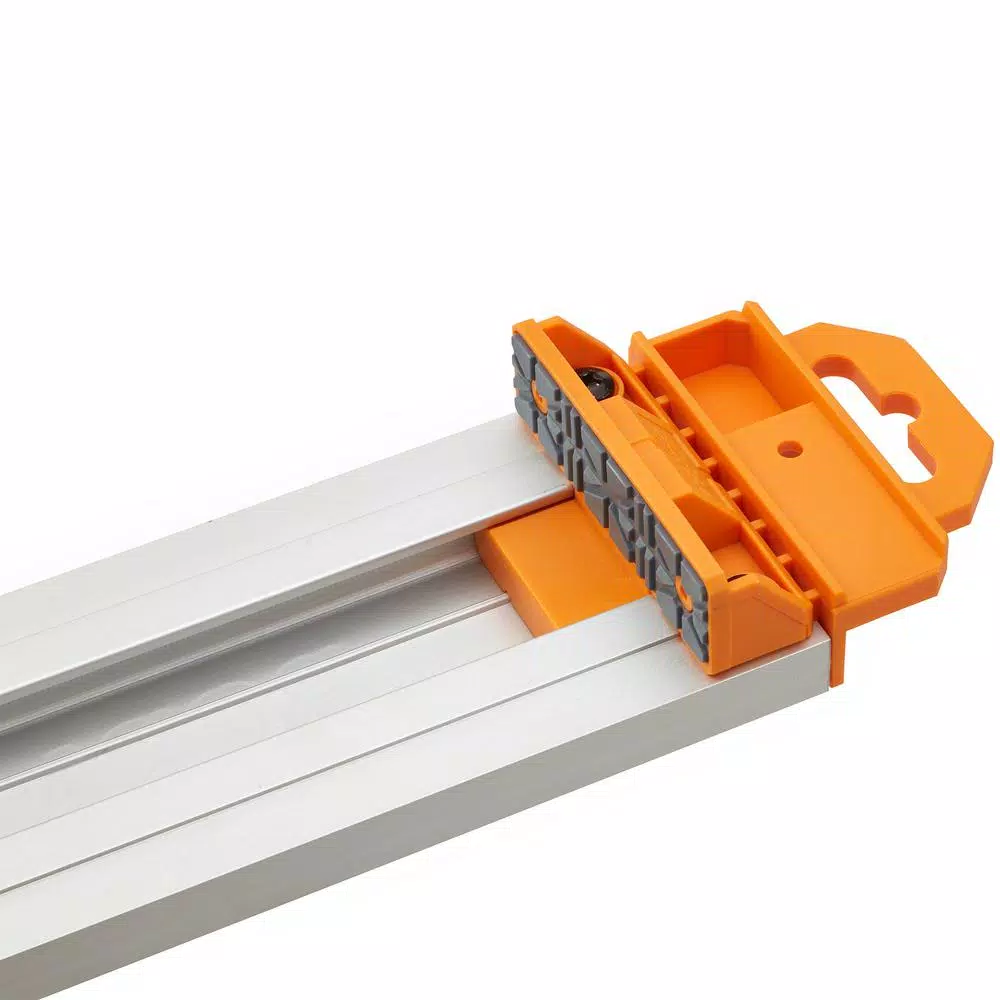

- Made of heavy-gauge, rigid aluminum for extreme durability

- Use with circular saws, routers, jig saws, and other portable power tools

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 4 lbs |

|---|---|

| Dimensions | 80.00 × 3.00 × 3.50 in |

| Color Family | Silver |

| Ideally Used With | Circular Saws |

| Material | Aluminum |

| Model | T-544100K |

| Power Tool Accessory Type | Other Accessory |

| Product Length (in.) | 108.5 |

| Tools Product Type | Other |

Reviews (86)

86 reviews for BORA NGX 100 in. Clamp Edge

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Tracks

Model# PM-7000iSaw Tracks

POWERTEC 36 in. Double Top T-Track with Predrilled Mounting Holes

Model# 71133Saw Tracks

Model# KMS8000Saw Tracks

Model# 198673-2Saw Tracks

Model# KMA2700Saw Tracks

Model# TTSAGSaw Tracks

Model# TTSWCSaw Tracks

General Tools 20 in. Heavy-Duty T-Track Professional Face Frame System

Model# 856T

Ryan Bogisich (verified owner) –

Excellent! I’ve been using home-made straight edges and boards that I’d screw down to a table, run my circular saw down it and sort of get me some straight cuts. But, it was practically laughable! Not to mention dangerous! Been wanting one of the saw guides for long time now!I got the Bora, I love it and I also wonder why I waited sooo long to buy me one. Just not tooo smart on my end!This one is an all aluminum straight edge, thick rigid plastic for the rest. Def not JUNK! When I lock it in place it don’t give, or “walk” on you, so to speak. Solid, thick plastic clamps! The aluminum is thick, I just don’t see it warping, bending or nothing like that anytime soon, at all. The saw slides right on down for a perfect straight cut every cut I’ve made so far! I can’t understand what took me sooo long finally get me one of these saw guides! Anyway, it’s simple to use, like they say, you only lock it from one side and no going to the other side of your table or whatever, no wasting time and walking around! Adjusts easy, none of that binding or anything like that while trying to adjust clamp! This is big help if you got a few cuts to make, if you just want a perfect cut each time or if you’re like me and don’t want to break out your table saw for everything a table saw is needed for! This turns my circular saws into table saws, simply and quickly! I love it. Did I mention I just can’t believe it took me sooo long to finally get me one of these??! If you’re on the fence about buying you one, I’d get this Bora, it’s sooo worth it, you’ll be glad you got you one, especially the “Bora” saw guide. They’re def high end!Should anything go bad or anything crazy happen with mine I’ll update my review, but so far, so excellent!

Madelynn Borer (verified owner) –

Bought this specifically to cut up plywood safely. The Bora NGX clamp definitely does this. For the price, this is a great little unit. It cuts spot on every time. Like any tool, you have to understand how it works and be aware of a few things to ensure it performs properly. On the NGX clamp, here are some things to keep in mind. Note, these are not in any way flaws. 1.) It does take about 15 minutes to connect your circular saw and dial the settings in to ensure adequate space between the cutting blade and the material. I have a DeWalt DWE575 and dialed it so the clamp is exactly 9/16 from my cut line. 15 minutes is not a lot of time, its easy. Do a few practice cuts. I recommend getting it dialed in to an exact measurement and there are markings on the slide piece to help you do this. Also recommend, clamp the top first, then do the 2 side clamps.2.) In the times I tried to use the right angle guide, it has not performed well. I bought the Premier set mainly because it was the only item available as the other parts (bought separately) were out of stock. In other words, I wouldn’t buy the Premier for this one part.3.) When cutting, be sure to put pressure on the right side of the guide. This ensures there is less blade deflection as you cut. 4.) Some folks complain the clamp down slide gets stuck. The trick is this… The gray handle and the orange edge has to come together in order to slide it. Simple. If it’s not sliding… just push them toward each other, you’ll feel a little click and it slides great.5.) Using the extension piece takes practice to ensure it’s spot on straight once the 4 screws are screwed in tightly. I find that screwing them in a little then pushing both slide components together and then screwing in the screws fully works best. Always check to make sure this is straight, common sense.6.) Some folks have mentioned the plastic construction of the base plate and clamp down. I’m not too worried about this. It’s pretty decent grade plastic. You’ll definitely get a few years out of this tool before anything breaks. If it does, just replace the part. Every tool wears.7.) The instructions… ha, this is one area that could use improvement. However, if you know how to use a circular saw and have actually changed out blades, the setup is pretty self-explainatory. Plus there’s plenty of videos out there.To close, even when I do get a table saw, I will still use the Bora NGX to cut full size plywood down to a more managable size. It is the safest way to do this and watching videos of people doing this on a table saw is pretty funny when you look at their eyes cause they know are uncomfortable.

Deontae Jaskolski (verified owner) –

Excellent alternative to buying a track saw system. I already had an old circular saw that was collecting dust, so it was nice to be able to put it to use. It does require some setup, so make the extra effort so your cuts are straight and true.

Lucius Kozey (verified owner) –

I really could have used this when I was building 4 barn doors for my basement. But I have two more to go and this will make the job much easier. It’s a pretty simple setup – the bars clamp easily to the work piece. And if it’s just straight cuts you can get away without the sled, just keep your saw pressed up against the track. The sled is a little tricky to attach straight but that’s more due to me being new to using a track saw. Couple of YouTube videos later and it was easy to figure out. And using the sled will ensure the saw doesn’t stray. All parts are very sturdy, very little flex in the bars. And the additional track clamps are a great addition – you can use bar clamps or C clamps, but to have clamps purpose built for this is much better. All in all, this is hands down better than screwing in scrap pieces of wood to serve as my guide and then having to fill holes. My only complaint, like others, is the instructions. Definitely not the easiest to follow.

Patsy Watsica (verified owner) –

I found this guide to be very solid as I did not see any measurable deflection when using it and it worked great as a guide. However, not a great track saw substitute. Using either the Saw Plate or just the guide, I found the cuts to be true. I also found that it helped when using the Saw Plate to use a dry lubricant (I used PTFE) on the guide as this allows the saw move much easier on the guide. The guide itself is easy to set up and when locked down it doesn’t move. Using the Saw Plate ensures that your cuts will be true. (I have been known to drift away from a guide.) I think the clamps that allow the guide to be used at an angle across a piece of plywood were very clever and worked great.However, I found the lack of instructions for setting it us to use like a track saw to be lacking to say the least. The instructions were just pictures without any written explanations of any of the steps. Consequently, it took me quite a while to get the saw(s) set up to see how they worked. In addition, it requires a metric allen wrench to set up a saw on the Saw Plate and this wasn’t included so I had to file down another allen wrench to fit. I set put the ‘non chip strip’ on the guide and tried the saw with 24-tooth blade and had minimal tear-out. However, when I switch to the saw with the 60-tooth blade I did have tear-out. Not sure why. I joined the two sections of the guide together to see how that worked and found the joint was not exact, and I had to file the bottom of the lead edge of the Saw Plate so it would not hang up on the joint.I recommend this product an the basis that you will get straight true cuts using the guide particularly when using the Saw Plate. I would have rated it higher if it in fact eliminated tear-out and the instructions were easier to follow. I also found that the nuts that are held in position when tightening the guides on the Saw Plate can rotate as they are not a snug fit in the slots they sit in.

Litzy Greenfelder (verified owner) –

Perfect for cutting ACM panel on my drafting table

Colton Goodwin (verified owner) –

This is a very convenient tool for cutting across large sheets, like plywood. Being 50″ wide means being able to handle 4′ sheets of plywood. Having a self locking feature is another nice feature. Simply line up on your marks, lock it into place and cut.

Avery King (verified owner) –

So glad I have one of these. While I admittedly haven’t used it much, it has been great the handful of times I have put it to use. Cuts now come out perfectly straight, which was always a struggle when simply following a line or using a makeshift guide out of a straight edge and clamps. I also own the saw plate for this guide but wasn’t sure that the blade and edge were parallel nor convinced that the saw would stay firmly in place, so I never actually used it to cut anything. One of these days I’ll give it another shot.Back to the guide:. There’s 50″ between the jaws, so cutting a 4×8 piece of plywood across the shorter side isn’t a problem. Once tightened down, they grip the edges really well – no issues with them coming loose. Now, I’m not sure if this is a design issue or a feature, but once you loosen the clamp, you kind of have to fiddle with it in order to move the jaw. Kind of annoying but not a deal breaker. Another thing that bothers me is the fact that the critical parts (jaws, clamp) are made out of plastic. Should be fine for regular homeowner use, but longevity is a concern. One thing to note is that the clamp sticks out close to 3″ when it is tightened – just something to consider as this may be a problem if you have to set this up on the floor.

Shanel Harris (verified owner) –

This is one of those tools I never knew I needed until I tried it. I’ve always used a couple of clamps and something with a “straight” edge to try to get a straight line. That involved finding something straight and of course running from side to side of the sheet to adjust the clamp. This tool takes all that extra effort away. Set it where you need it and quickly clamp it at one end, then cut. Done. It’s very light, very easy to maneuver, and the adjustable clamp slides easily in the track.Pair the clamp with Bora Saw Plate accessory (https://www.homedepot.com/p/BORA-NGX-55-in-Saw-Plate-with-Non-Chip-Strip-544001/311799074), and move your saw effortlessly along the track. These clamps and accessories basically turn your circular saw into a unisaw!

Bryce Runolfsdottir (verified owner) –

I deserve a hard kick in the pants – for not getting one of these tools years ago. Like many DIYer, I have struggled with using a piece of extruded aluminum or angle iron and a pair of clamps to cut straight lines (hopefully) in large sheets of material. The setup was time consuming and the cut wasn’t always straight. This tool virtually eliminates both of those problems. Very easy to use – with excellent clamping force – and sturdy enough to always get straight cuts. They also have a saw adapter (purchased separately) that holds the saw in a tray which slides along on top of the saw guide – eliminates the possibility of the saw drifting off track. This tool is a must have for any volume of 4X8′ cutting.

Brandt Hermann (verified owner) –

I have this and the extension for a 104″ reach to rip sheet goods. But buying the two thinking you are going to reconfigure each time you “rip” and “crosscut” a 4×8 sheet is not going to work–too long and too much wear on the parts. It holds well, but takes time to set up straight. A little pricey!

Linnea O’Hara (verified owner) –

Super handy for trimming doors to fit after a whole home flooring project.

Aiden Runolfsson (verified owner) –

Easy to use guide clamp that makes accurate cuts quickly. Saw base is easy to mount to your saw and easy to dial in. Great setup for ripping and cutting down plywood.

Hilton Bode (verified owner) –

It is a nice product but the clamp pressure is not that strong, it can slip and will if there is any pressure from the saw. Also the height or thickness is a little to much who’s had only allows the skill saw to be used in one direction. Slipping while clamp is set is main concern.

Shawna Vandervort (verified owner) –

This is a very useful tool overall, but the adhesive on the chip strip is weak and didn’t last for two days. Since the strip is not a necessary item, I can’t complain too loudly since I really like the rail and bracket.

Rigoberto Crooks (verified owner) –

I like that the t-tracks accept 1/4 x 20 bolts. I hope to get lots of use from it. It seems pretty solid.

Terrance Bashirian (verified owner) –

Works great especially with worx exactrack circular saw. Cuts through 4 x 8 plywood straight every time!

Eloise Conn (verified owner) –

It makes cutting perfect straight lines with a circular saw easy. This will cut across the 48” side of plywood or any sheet good. You can also add another 50” section and rip the full length of a sheet of plywood. Cheaper than a track saw.

Aron Wiegand (verified owner) –

This is a great tool. I’ve been fiddling for years with just clamping a long piece of straight wood to plywood when I need to make cuts with any precision. So, three clamps and a bulky piece of wood. It works, but it’s a pain. This tool allows you to clamp on sheet goods up to 4 feet wide and get cutting right away. It seems to clamp on consistently at a right angle, but I’m a bit compulsive, so I do check each time. You will have to do some calculation to know how far to set the clamp from where you need to cut–you have to calculate some offset from your saw’s guide. Unless–you can get the Bora Saw Plate that fits with this. If you have the saw plate, you fit your circular saw to the plate, attach an additional guide to the clamp edge, and after setup, you can set the guide to where you want your cuts. This speeds up the process like crazy, and basically gives you the capabilities of a track saw from your circular saw. Great stuff.

Orlo Bosco (verified owner) –

Excellent saw guide, an important tool if you dont own a table saw or cant lug a large sheet of plywood across a table saw. It is very easy to use and the clamp is strong. The clamp has a temporary setting before you lock it into place. It locks very tight and may bow up so you should leave the clamp a little loose before cinching it down. It holds onto the piece nicely. For sawing, all you need to do is know the distance from the edge of you saw plate to the cut (mine is 4″) and set the clamp that distance away. The clamp can fit easily across 4 foot sheet and is durable as well. It can also be used for scoring drywall. This is a great tool to have in the workshop and hangs easily on a nail for storage. In the past I have used my most straight piece of wood and clamps. This saw guide saves me time and hassle.