Delta 15 Amp 13 in. Portable Thickness Planer

$396.64

Get hands on a fantastic and strong addition to accomplish various tasks easily with the selection of this exclusive Delta Portable Thickness Planer.

In stock

Description

The Delta 22-555 Portable Thickness Planer is great for professional results in the woodworker’s shop. It features two polyurethane feed rollers for a no-slip grip on the work piece; positioned close to the cutter head to improve work piece finish. The machine also has precision machined steel cutter head for endurance and accuracy with a stainless steel bed that reduces friction and improves motor efficiency.

- Powerful 15 Amp motor capable of handling the demands of a small shop

- 4 column designs provides excellent stability for smooth, accurate planning over many years of use

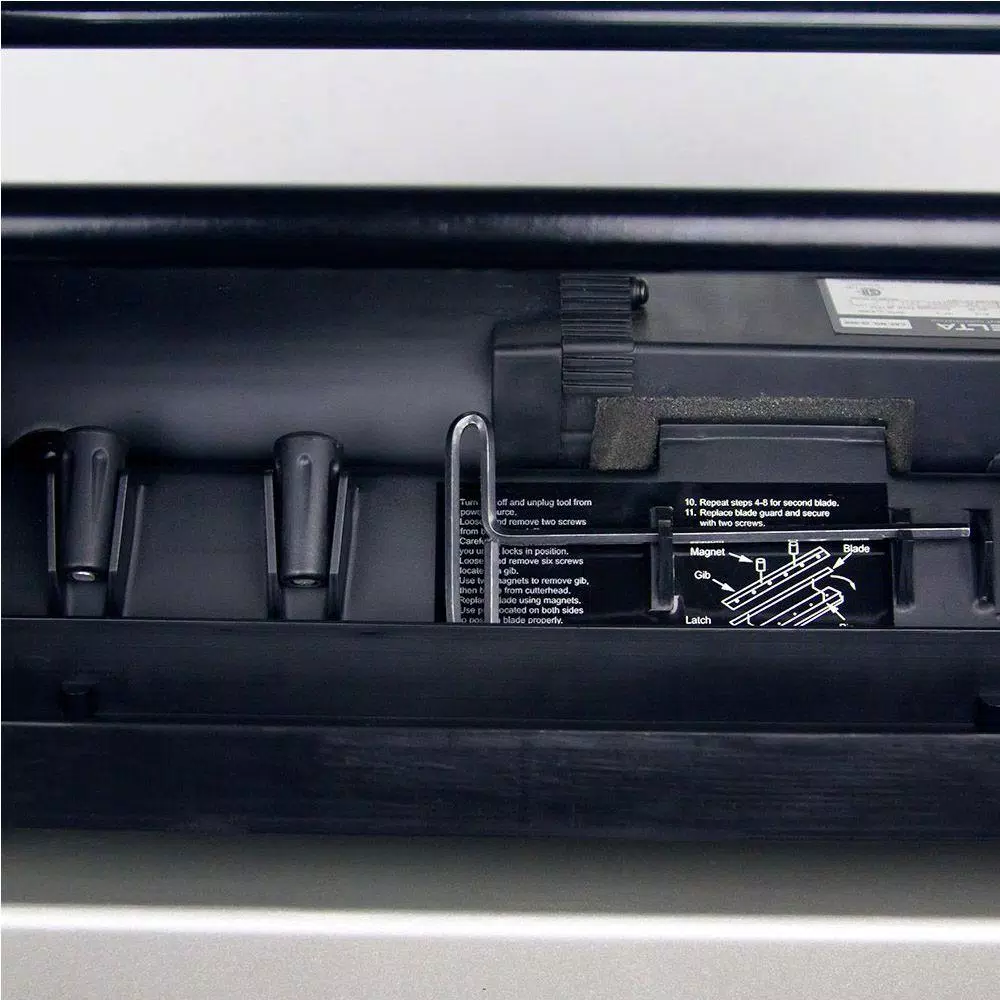

- Quick change knife system with dual edge disposable knives lets you change knives without difficult-to-use alignment jigs

- Adjustable in feed and out feed tables to better support long pieces and reduce snipe

- Reversible dust port allows you to collect chips from the right or left side of the planer

- 2 polyurethane feed rollers for a no-slip grip on the workpiece; positioned close to the cutterhead to improve workpiece finish

- Precision machined steel cutterhead for endurance and accuracy

Additional information

| Weight | 63 lbs |

|---|---|

| Dimensions | 21.70 × 14.00 × 12.10 in |

| Amperage (amps) | 15 |

| Bench & Stationary Tool Type | Planer |

| Blade(s) Included | Yes |

| Color Family | Gray |

| Color/Finish | Gray |

| Condition | New |

| Maximum Board Thickness | .125 |

| Maximum Speed (rpm) | 10000 |

| Maximum cut depth (in.) | 0.09 |

| Minimum cut depth (in.) | 0 |

| Model | 22-555 |

| Number of Cutting Blades | 2 |

| Portability | Bench |

| Tools Product Type | Power Tool |

Reviews (84)

84 reviews for Delta 15 Amp 13 in. Portable Thickness Planer

Only logged in customers who have purchased this product may leave a review.

Related products

Woodworking Tools

Model# DW682KWoodworking Tools

Porter-Cable 11 Amp Corded 1-3/4 Horsepower Fixed Base Router Kit

Model# 9690LRWoodworking Tools

Model# 892Woodworking Tools

Model# DW734Woodworking Tools

Bosch 12 Amp 2-1/4 in. Corded Peak Variable Speed Plunge and Fixed Base Router Kit with Hard Case

Model# 1617EVSPKWoodworking Tools

Model# DW735Woodworking Tools

Model# 5615-21Woodworking Tools

Model# 708620B

Bernard Jacobson (verified owner) –

Just fine for the money. I wanted the Dewalt 3 blade 13 inch but couldn’t afford it now.

Zora Schaefer (verified owner) –

Whether to buy this machine depends on what you are trying to do from a woodworking standpoint. In the past, I have gone to the big box store and tried to find the flattest, truest boards in the rack. That’s fine as far as it goes. I go into the details of how to get the best out of this machine below, but before I do that, I want to make sure that this point doesn’t get lost: When I planed my boards with this machine, they were, pardon the exaggeration, glassy. No ridges, no tear-out, no nothing. Perfectly smooth. I’m not even sure that they would need to be sanded to take paint, though the blades are brand new.That was true regardless of the direction I ran the boards. Maybe I was lucky, but the direction of the grain often determines if there will be tear-out, pieces of wood torn from the surface. None of my boards showed that, and I didn’t do anything to prevent it, like checking the grain on the boards. The wood was poplar, which is a medium hardwood. Maple or oak might have been more problematic. I expect it wouldn’t be anything too hard to deal with even with the hardest woods. However, doing real woodworking involves much more in terms of getting the boards that you’ll use to be exactly right. Even small bows or twists can lead to a bad result, or at best a mediocre one. To get the best result, you need to get 4/4 lumber and mill it to the dimension that you need.Doing that requires several machines, one of which is a jointer, which allows you to create a single flat surface on the board. Once you have that flat surface, you can then plane the board, using this machine, to the thickness that you need. Better still, if your project requires boards of the same width, such as for stiles and rails for doors or for face frames, you can achieve that with this planer. One regular complaint about planers is “snipe,” the tendency of the planer to cut deeper at the start and end of the cut, leaving a trough, if you will, at each end. There are several cures for that problem, which have to do more with how the stock is fed and less to do with the capabilities of the machine itself.Suffice to say, I planed three dozen short boards today with this machine, short being anywhere between 18 and 32 inches. None of them was sniped. Part of that was making an adjustment of the infeed and outfeed tables to make them truly level with the bed table of the planer. If the board goes in and comes out exactly level, it won’t snipe. That is easier to do with short boards than with long ones, but in all cases, if the board remains truly horizontal as it runs through the planer, snipe won’t occur. To think about that another way, if you are putting a long board into the planer, and if you allow the back/trailing end of that board to dip, even just a little, it will raise the front end of that board, and the planer blades will snipe it. If you put the board through on a plane that is horizontal to the bed of the planer, you minimize snipe or avoid it altogether. Most hobbyists won’t be able to use this tool to its best potential, but if you have a jointer and want to mill your 4/4 stock to be true on all four sides, this plane, or some other, will be necessary. What I can tell you is that fthis one works as well as you will ever need, and the cost is far below that of competitors.

Osvaldo Kuphal (verified owner) –

was everything I expected. Great product

Everett Carroll (verified owner) –

Best value for the price