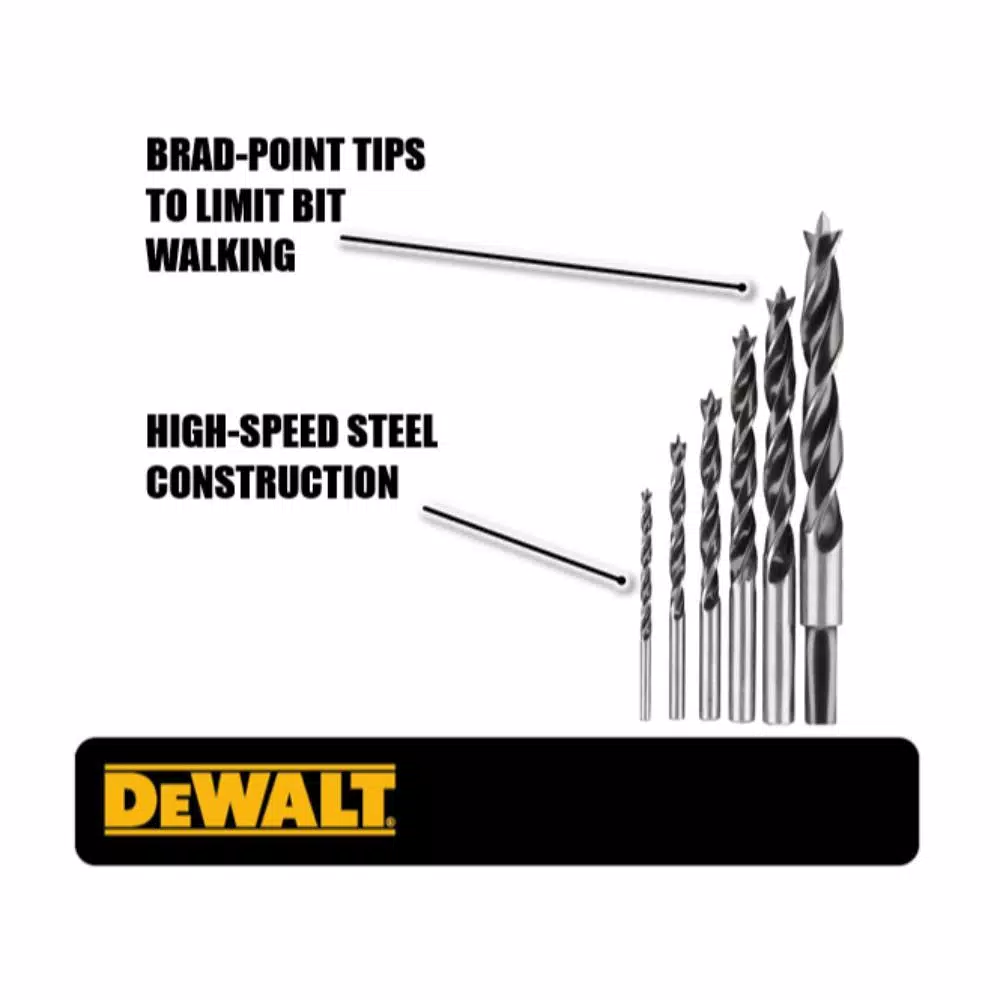

DEWALT High Speed Steel Brad-Point Drill Bit Set (6-Piece)

$14.97

The 6 bits that comprise the DEWALT 6-Piece Steel Brad-Point Drill Bit Set feature precise cutting edges that help limit splintering. Each steel bit uses brad-point tips and engineered flutes to help prevent drill walking and remove chips. Set includes 1/8 in., 3/16 in., 1/4 in., 5/16 in., 3/8 in. and 1/2 in. bits.

Only 10 left in stock

Elmo Mayert (verified owner) –

For the PRICE.. this is a ‘good’ set. [3.5 STARS]I bought them to dowel Baltic Birch (did a good job) and have used them on red & white oak, pine, poplar & particle board. These work fine on soft woods but struggle on hardwoods… they are not as sharp as they should be. The smaller bits will bend if pressed too much, which you might be tempted to do as they drill rather slowly thru hardwoods (should be sharper). I like the fluted design and, obviously, the brad points. I’m more than a bit (no pun intended) worried about using them on my purple heart.but for the price and general, average use.. I would recommend.

Carlotta Deckow (verified owner) –

Very nice set of bits. Start drilling immediately without having to create the divot first that a normal bit does. Only issue is that the set is missing he 3/16 diameter bit. I use that a lot. Maybe I just work with strange dimensions.

Bernita Willms (verified owner) –

Nice set of bits. They work well.

Josue Halvorson (verified owner) –

I am a big DEWALT fan … my Cordless and Corded drills are DEWALT. This set was purchased for one specific reason, one specific project … making a Dremel Tool and Accessory Box to neatly and efficiently accommodate the various bits and attachments I use. The main Brad Bit I needed was the 1/8″, which is the size of the Dremel Accessory Shanks. I was using a Drill Block in order to drill straight holes therefore there was no side-to-side pressure on the Bit. The 1/8″ DEWALT Brad Bit broke after three (3) … and I was drilling into soft wood. That Bit should have been able to drill hundreds of 1/8″ X 1 1/2″ holes without a problem. I ended up using a regular 1/8″ Bit but in truth the Brad would have been more precise. Disappointed.

Baron Keeling (verified owner) –

Worked as expected.

Ward Lemke (verified owner) –

Worked as it should

Camden Hermann (verified owner) –

Great drill bit set makes super clean holes.

Hassan White (verified owner) –

Bits are straight however extra sharpening may be required if you are especially drilling into harder wood. I recently purchased this set to do dowel joinery.

Nella Davis (verified owner) –

They’re as good as one could expect for the price. Doing fine woodworking, I had to sharpen the bits to get them up to where I needed. Other DeWalt bits have lasted me years of general heavy use, these are sturdy, but obviously not even comparable to a real set of brad point bits.

Oran Spencer (verified owner) –

These Brad-Point Drill Bits did the job and more. Its speed, power and efficiency was outstanding. I’m a happy camper because of this product. Another excellent work from DeWalt!..

Samir Powlowski (verified owner) –

Dewalt always does it better.

Laurel Wisozk (verified owner) –

I haven’t used them as of yet, however, the drill bits appear to be of high quality as far as their manufacturing and conformity to their advertised appearance.

Osvaldo Klein (verified owner) –

Very good

Aron Russel (verified owner) –

I drilled over 2000 holes in a block set I made for my Grandchildren, stayed sharp and true.

Clement Mueller (verified owner) –

First, let me state that I am not a wood working person with a vast experience and array of tools. My radio-controlled model airplane building and crash repair needs require drilling holes every now and then. Also, I don’t get paid for this review, but I am an avid photography enthusiast. Some of us describe ourselves as a jack of all trades and master of none.Drill bits have always been in my tool assortment. For hobby birch plywood, a cleanly drilled hole will do away with or minimize the sanding efforts that are difficult when splits occur. Strength for this area keeps my airplanes together longer. You know what I am talking about.For decades I have been buying what I will call the “common” drill bits. They work well. I am not knocking them as they get a lot of use from me. So, why get brad point drill bits? Frankly, the photos show why. The result is a clean hole with the absence of splits. For both holes there was no backing material under the small piece of plywood. Both hole tests involved a slow feed pressure. One hole requires a lot of sanding and repositioning of the split fibers to get it to look like the brad point hole.Brad point drill bits have a long center point that works out well if you have a pilot hole in your work. The “spurs” on the outer edge are probably the reason for the clean-cut holes. I am not an expert, but I know which drill bits I will be reaching for.