Drill America 12 in. L High Speed Steel Aircraft Extension Drill Bit Set (5-Piece)

$45.89

Acquire a modern and comfortable tool to finish your drilling tasks in the jobsite with Drill America L High Speed Steel Aircraft Extension Drill Bit Set

In stock

Description

Drill America High Speed Steel Aircraft Extension Drills are good for most general purpose applications. These drill bits offer a combination of hardness and toughness for wear resistance. Black oxide treatment adds lubricity and creates small pockets on the surface of the tool that act to hold coolant near the cutting edge. Extra-long for when extra reach is required.

- Sizes included are 1/4 in., 5/16 in., 3/8 in., 7/17 in. and 1/2 in. with overall length of 12 in.

- High-speed steel tools are good for most general purpose applications, offering a combination of hardness and toughness for wear resistance

- Have a black oxide surface treatment that is abrasion resistant, reduces chip welding and improves chip flow

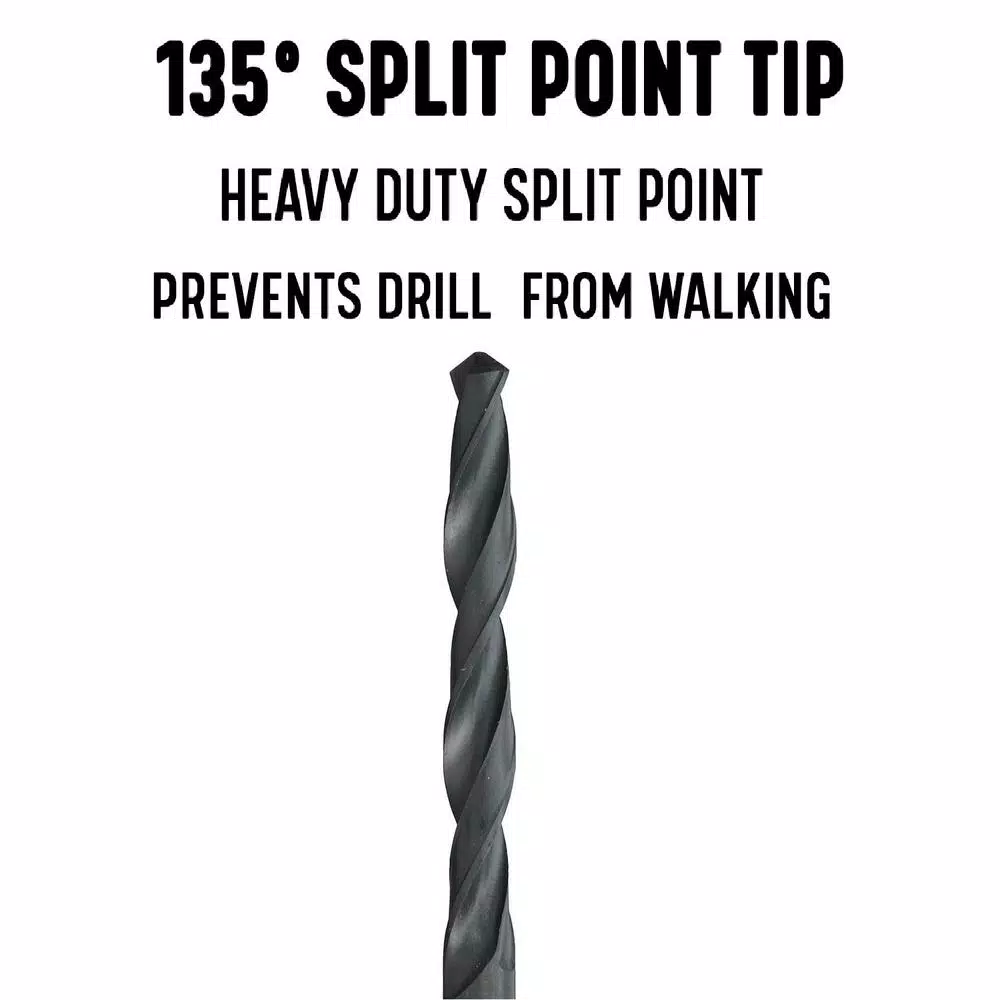

- 135° split point is self-centering and reduces thrust

- Manufactured to National Aerospace Standard 907

- Drill America aircraft extension drills are available in 6 in. and 12 in. overall lengths when extra reach is required

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 2 lbs |

|---|---|

| Dimensions | 12.00 × 5.00 × 2.00 in |

| Bit Material | High Speed Steel |

| Drill Bit Type | Twist |

| Drill Bit Type(s) Included | Twist |

| Individual/Set | Set |

| Model | POUA/CX12 |

| Number of Pieces | 5 |

| Self-Feeding | No |

| Shank Style | Straight |

| Tools Product Type | Power Tool |

Reviews (4)

4 reviews for Drill America 12 in. L High Speed Steel Aircraft Extension Drill Bit Set (5-Piece)

Only logged in customers who have purchased this product may leave a review.

Related products

Drill Bits

Milwaukee 18 in. x 7/16 in. QUIK-LOK Universal Extension Bit

Model# 48-28-1050Drill Bits

Bosch Carbide-Tipped Rotary SDS-Plus Hammer Bit Set (7-Piece)

Model# HCK001Drill Bits

Model# FB-005Drill Bits

Model# DW2535Drill Bits

Model# 282269Drill Bits

Milwaukee Selfeed High-Speed Steel Wood Boring Bit Set (7-Piece)

Model# 49-22-0130Drill Bits

Model# 48-25-2252Drill Bits

Model# FB-015

Pablo Schoen (verified owner) –

One of the bits broke as soon as it hit a hard spot in the wood.

Antonetta Beier (verified owner) –

A must have set of extension drill bits for the shop and the tool box. Over the many many years of being an electrician/ home builder / mechanic/ and just an overall jack of all trades I have probably purchased more drill bits than I can count. It used to be that a good set of drill bits was pretty expensive, but not so any more, so you can now own a good set of regular size drill bits and a set or more of these longer drill bits. This 5 piece set has the ones that I use most of the time, but it never hurts to spend a little more and get a set with 7 or more.

Dorcas Feeney (verified owner) –

These worked perfectly for drilling through 6-10” diameter tree logs on our rustic porch project. They handled both wood and steel easily and stayed sharp throughout the job and are great value for money.We’re building a rustic porch from real cedar and pine logs and wanted to hide the steel mounting brackets inside the logs. We used the ¼” bit to drill pilot holes through the tree logs so we could locate the metal brackets inside. Since we were bolting through the logs with ¾” bolts, I needed a longer drill to ensure that I could get through the entire log in one go so that the holes would line up properly from front to back.Since the drills are 12” long, I found that a rafter square was very helpful in making sure that the holes are drilled square to the wood. I just rested the rafter square on the log and then lined up the drill bit to make sure that the hole was a close to 90 degrees as possible and it worked pretty well.The flutes are quite short (2.5” on the ¼” drill increasing to 4.5” on the ½” drill) so I found that I had to back out the bit a few times to let the swarf and sawdust clear from the end of the drill. The holes were clean and tight however.In some cases, there were steel mounting brackets embedded in the end of the logs and the High Speed Steel drill tip had no problem drilling through the 3/16” thick steel so that we could make one pass through the entire width of the log. Just make sure to drill the metal on low speed on your drill to preserve the drill tip from overheating.We also used the larger ½” bit for drilling the holes for 5/8” lag bolts in pine log ‘K’ braces with similar success. We pre-drilled the pine ‘K’ brace and then held it in position and drilled into the posts and beams. As with the ¼” bit, we had to back the bit out a couple of times to clear the flutes. We then enlarged the top 2” of the hole with an 11/16” auger to accommodate the lag bolt shoulder and the bolts went in perfectly.The ¼” drill was still in good shape after drilling through 11 cedar posts which also required drilling through 22 pieces of 3/16” metal plate.When not in use, the drills come with a plastic pouch which rolls up for compact storage in the tool box and also helps keep all the drills to hand when you’re using them on-site.

Euna Harris (verified owner) –

Well heat treated HSS. HSS is High Speed Steel that is used in machine shop for cutting tools used on steel and other materials. This set of drills is well heat treated, meaning they are hardened and properly tempered for drilling steel. Exactly like the drills I have used in machine shop for decades. I have purchased tools stamped HSS that were not heat treated and about worthless for cutting steel. Be alert to proper speeds for these drills. You CANNOT use these in a drill press designed for wood because you cannot run the RPM’s slow enough and you WILL burn up the drill. AND the larger the drill diameter the slower it needs to run. There are speed charts available on the Internet for drilling steel and aluminum. The SPLIT POINTS are very well done. A split point can often be used to drill from solid instead of needing to step drill, meaning you do not need to drill smaller holes before the full size. And the lips are perfectly on center producing 2 chips that are equal thereby drilling an on size hole, not oversize.They come in a roll up plastic carry pouch with separate pouch for each drill.