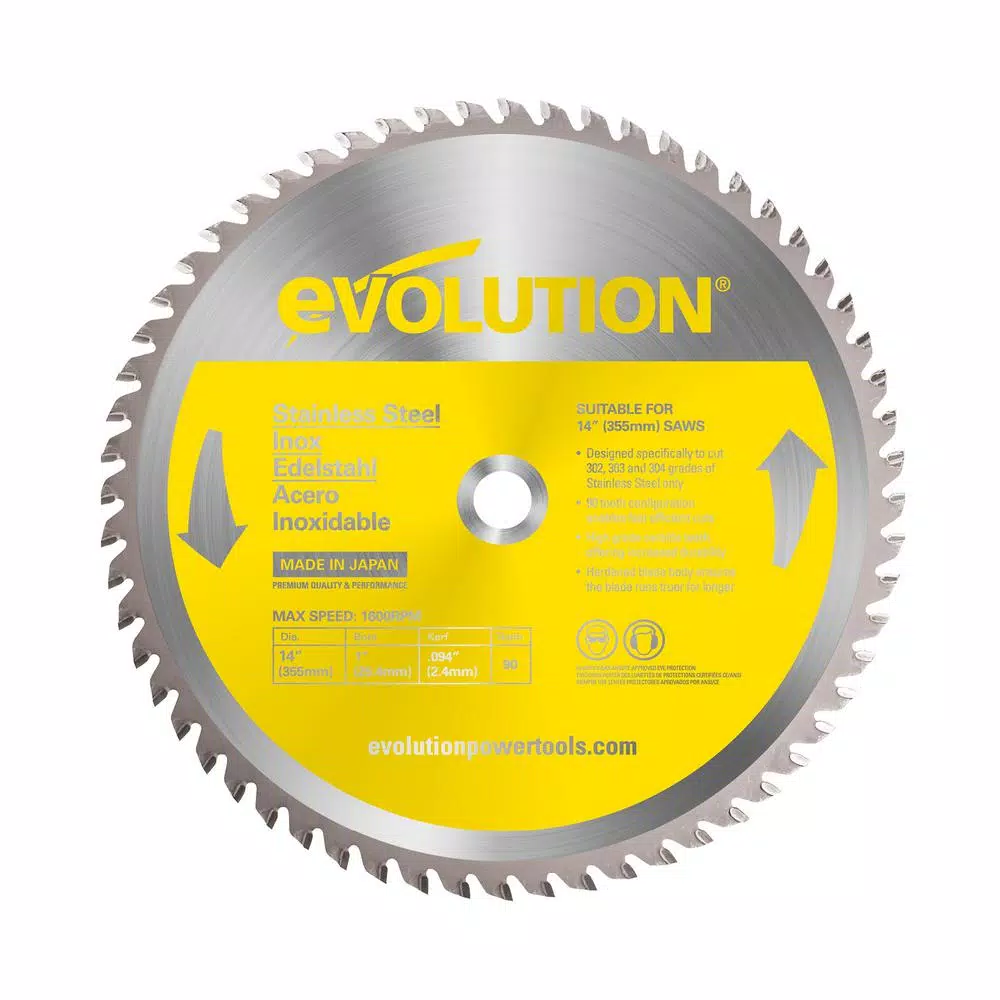

Evolution Power Tools 14 in. 90-Teeth Stainless-Steel Cutting Saw Blade

$131.83

Designed for cutting stainless Steel. Evolution metal cutting blades use dry cut technology. Cutting with very little heat and few burrs.

In stock

Description

Designed for cutting stainless Steel. Evolution metal cutting blades use dry cut technology. Cutting with very little heat and few burrs.

- Material applications include: square tube, angle iron, stainless steel plate, diamond plate, pipe and tube.

- 90 carbide teeth

- 1 in. arbor size

- 0.094 in. kerf

- 1600 RPM

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 4 lbs |

|---|---|

| Dimensions | 16.00 × 18.00 × 1.00 in |

| Arbor Size | 1 in |

| Color Family | Yellow |

| Material Cut | Metal |

| Model | 14BLADESS |

| Number in Package | 1 |

| Number of Teeth | 90 |

| Power Tool Accessory Type | Circular Saw Blade |

| Saw Blade Diameter (in) | 14 |

| Saw Blade Material | Carbide |

| Tools Product Type | Power Tool |

Reviews (10)

10 reviews for Evolution Power Tools 14 in. 90-Teeth Stainless-Steel Cutting Saw Blade

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

DEWALT 12 in. Miter Saw Blade 32-Teeth and 80-Teeth (2-Pack)

Model# DW3128P5Saw Blades

Milwaukee 6 in. 24 Teeth per in. Thin Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5186Saw Blades

Model# D0740RSaw Blades

Model# 48-00-8788Saw Blades

Model# D1060XSaw Blades

DIABLO 7-1/4 in. x 24-Teeth Tracking Point Framing Saw Blade

Model# D0724RSaw Blades

Milwaukee 44-7/8 in. 18 TPI Bi-Metal Deep Cut Portable Band Saw Blade

Model# 48-39-0520Saw Blades

DEWALT Bi-Metal Reciprocating Saw Blade Set (15-Piece) with Tough Case

Model# DW4890

Nayeli Franecki (verified owner) –

Based on the reviews I was expecting more than the blade delivered. Stainless steel is tough on cutting tools but the right tool does a good job and this blade doesn’t do the job. In one review, I read that a customer had made fifty cuts in 1″ sch. 40 pipe. Not this blade. I’m cutting 1″ X 1″ X .062″ tubing and I get about 10 cuts before the blade starts leaving burrs that need to be sanded before welding fitup. There are no vibration dampening laser cuts in the blade and it’s noisy starting with the first cut. I think a lot of the noise is is about tooth geometry. I have tried three different brands and this one is the worst. My #1 choice out of three brands delivers quality cuts (approx.30) without significant burrs. All of the blades I have tried are comparably priced and I paid $11 more for this blade than my first choice. The cost per cut is significant when you only get about 30-40 cuts. The accuracy of the cut is also lost with this blade as it begins to get get dull. I also built a fixture so the tube is clamped in the saw so the blade is cutting through a diamond shape not through a square with a flat surface where heat can build up quickly. Heat is a detriment to the life of any cutting tool.When purchasing this blade or a blade designed for stainless (any carbide tooth blade) I suggest that a user not push the blade past the limits of quality cuts. A good blade sharpening service will charge about one third the cost of the blade if the teeth are not chipped or missing. Of course they will replace chipped or missing teeth for an extra charge.I mention the sharpening because after I had the blades ( I purchased two) sharpened there was no change in performance.

Candace Jones (verified owner) –

This blade works great. My regular blade I got with the saw lasted a very long time … until I started cutting stainless steel with it. When the performance was starting to really lack, I purchased a new one and also ordered this blade as well. It cuts through stainless like butter.

Candelario King (verified owner) –

Worked well but only have cut about 20 pcs

Helena Littel (verified owner) –

Great blade

Anita Wintheiser (verified owner) –

We use this blade on our Evolution Chop saw in our machine shop. This blade is very versatile and has cut everything from hardened steel to aluminum and even plastic without gumming up. Definitely recommend getting this one.

Erik Watsica (verified owner) –

Nice saw. Works well for my needs.

Jaron Murphy (verified owner) –

This blade has cut through multiple pieces of stainless bar stock, mild steel tubing and structural steel. It works great for cutting. Two things to note: Don’t use it on really thin wall tubing, it loses its teeth sometimes. Secondly, it is NOT an abrasive blade. Don’t push down on it if you want it to last. Let the blade do the cutting with light pressure and it will work great.

Emelie Ratke (verified owner) –

Based on the reviews I was expecting more than the blade delivered. Stainless steel is tough on cutting tools but the right tool does a good job and this blade doesn’t do the job. In one review, I read that a customer had made fifty cuts in 1″ sch. 40 pipe. Not this blade. I’m cutting 1″ X 1″ X .062″ tubing and I get about 10 cuts before the blade starts leaving burrs that need to be sanded before welding fitup. There are no vibration dampening laser cuts in the blade and it’s noisy starting with the first cut. I think a lot of the noise is is about tooth geometry. I have tried three different brands and this one is the worst. My #1 choice out of three brands delivers quality cuts (approx.30) without significant burrs. All of the blades I have tried are comparably priced and I paid $11 more for this blade than my first choice. The cost per cut is significant when you only get about 30-40 cuts. The accuracy of the cut is also lost with this blade as it begins to get get dull. I also built a fixture so the tube is clamped in the saw so the blade is cutting through a diamond shape not through a square with a flat surface where heat can build up quickly. Heat is a detriment to the life of any cutting tool.When purchasing this blade or a blade designed for stainless (any carbide tooth blade) I suggest that a user not push the blade past the limits of quality cuts. A good blade sharpening service will charge about one third the cost of the blade if the teeth are not chipped or missing. Of course they will replace chipped or missing teeth for an extra charge.I mention the sharpening because after I had the blades ( I purchased two) sharpened there was no change in performance.

Randy Mann (verified owner) –

Cuts Sch 40 SS pipe with minimum burr and the blade has cut 50 pieces of 1″ diameter pipe so far.

Enoch Langworth (verified owner) –

This was a great value and shipped to us quickly!