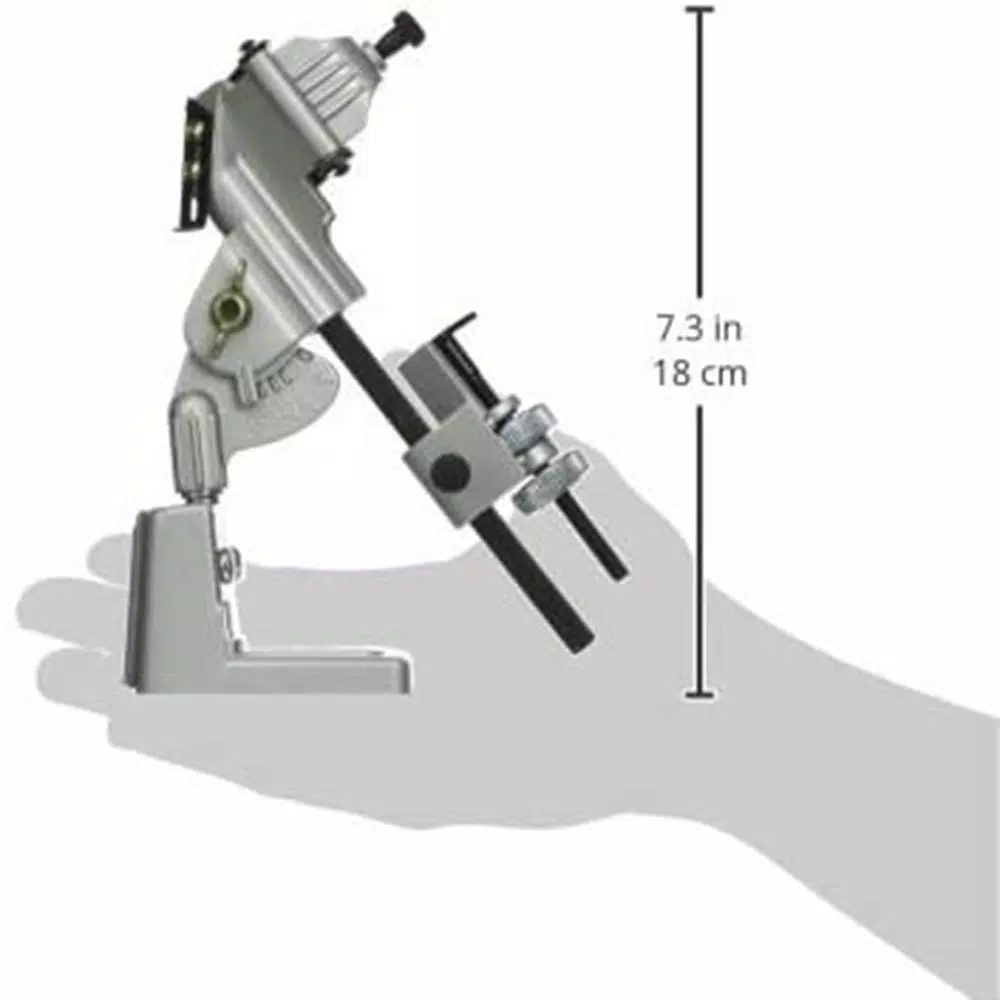

General Tools Drill Bit Sharpener & Grinding Tool Attachment

$23.72

Drill Grinding Attachment – Put new life into old drill bits, putting that brand new, out-of-the-box tip on them quickly and easily. Works great with larger, more expensive bits. Even works on countersinks.

In stock

Description

Extend the life of your drill bits with the General Original Drill Grinding Attachment. This durable tool quickly sharpens them back to factory tolerances. The angle adjustment gauge allows you to match the point angle of nearly any bit and even works on countersinks. Designed with a pivoting neck for simple grinding of both sides of the bit. For use with ANSI, OSHA and UL approved standard electric bench grinders or surface grinders.

- 3 in. alnico magnet with 50 lb. pull capacity

- Fits 1/8 to 3/4 in. bits

- Guide sleeve prevents screw wobble or disengaging from the bit, magnetic screwdriver bit tip for fastener retention

- Non-marking depth stop cap protects material surface

- Sliding, Spin-free depth stop/screw guide sleeve

- 1/4″ quick change compatible and impact hex shank

- Removable 1 in. driver bit

- Depth collar lock

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 1.8 lbs |

|---|---|

| Dimensions | 3.00 × 7.00 × 13.00 in |

| Color Family | Silver |

| Drill Attachment Product Type | Grinding Attachment |

| Material | Metal |

| Model | 825 |

| Power Tool Accessory Type | Other Accessory |

| Product Length (in.) | 7.38 |

| Tools Product Type | Power Tool |

Reviews (24)

24 reviews for General Tools Drill Bit Sharpener & Grinding Tool Attachment

Only logged in customers who have purchased this product may leave a review.

Related products

Drill Attachments

Model# 73630Drill Attachments

Model# 272701Drill Attachments

Model# 45-01801Drill Attachments

Model# 1314Drill Attachments

Model# 53715SENDrill Attachments

Model# 31874Drill Attachments

Jacobs Professional Grade 3/8 in. Keyless Drill Chuck with 3/8 in. 24-Mount

Model# 30354Drill Attachments

Model# 74068

Zula Hill (verified owner) –

I am happy with the drill sharpening fixture but the instructions could have been better!

Mathew Renner (verified owner) –

I definitely need to sharpen some of my drill bits and that what i will do tomorrow .My neighbor saw this and said can we shapen some drill bits of mine also and of course I said yes.i have a few bits that need sharpening so it is definitley going to come in very handy for me and my neighbor lol.To all my friends i think you need to check this out so if you need drillbits shrpened this will definitely work for you.

Seamus Satterfield (verified owner) –

To those complaining about the use of the word drill and not bit, professionals call drill bits “drills” and that is the proper term. That’s why they call the electric tool a “drill motor”. Hope this helps

Nat Tremblay (verified owner) –

This little drill sharpener is well worth every penny that it costs. This sharpener will work on bits that range in size from 1/8” to 3/4”. For years I have sharpened drill bits by hand and with other devices and nothing comes close to this little jig. This drill sharpener is easy to use and easy to setup on almost any grinder or belt sander. I set mine up on my 2” x 72” belt sander instead of the side of a grinding wheel. One of the hard parts to sharpening brill bits is getting the same geometry on both cutting faces on the drill bit. This sharpener does this with ease. One note: take small grinding passes for two reasons, this avoids over heating the drill bit and it keeps both cutting faces even so they both are cutting equal amounts material. Once the sharpener is set up its just a matter of getting a feel for what you need to do. As the bits get smaller the setup becomes more critical due to the small amount of bit that can overhang the end of the sharpener. Once set up, bits can be sharpened very quickly, and they look as good as new or better. As shown in the attached pictures the bit is clamped into the sharpener and moved in a sweeping motion across the grinding surface. Overall this is a tool that almost anyone can use, its going to pay for itself very quickly in reduced cost of replacing drill bits. I highly recommend this product as almost indispensable for almost any shop or DIY enthusiast.

Emmett Carter (verified owner) –

More than 4 hours on a Saturday trying to drill 3 holes in 1/8 steel, damaged 2 drill bits. I got one of these found a rusty dull drill bit sharpened it with this tool and in less than 10 minutes drilled 3 holes in 1/8 steel with a rusty old drill bit sharpened with this device. I beleave this device was available 40 years ago under another name brand until it was discontinued. Highly recomend.

Madaline Goldner (verified owner) –

This sharpener is the best $25 I have spent. I did a lot of research on the internet and on YouTube, which really helped to do the set up and use. I also found a detailed PDF on the internet (search words “general tools drill sharpener”). I found this sharpener to give excellent results on bits from 1/8” to ¾” when I used it with my 8” shop grinder. The best setup is to mount the sharpener on a secure surface with a 2-1/4” distance from the middle hole of the sharpener to the face of the grinder wheel. I also suggest the first drill bits be at least ¼” to 3/8”, as trying with 1/8” is too hard for learning the first time. The key to getting the best results is to make the sure the overhang distance is measured (1/2 the diameter of the drill bit) and then locking down the trough feed nut with the lip rest in the drill bit groove (to keep it from rotating). Then you adjust the slotted base to the point where the swing or sweep of the fixture just barely kisses the grinding wheel to the bit at the outer arc. This will allow you to minimize the amount of material removed and still get full cut for the 118 degree angle of the bit. I use a black permanent marker to coat the cutting surface prior to sharpening and after the first sweep to make sure the new cut has been made on the whole cutting edge of the bit. If your cut doesn’t completely go to the outer OD, just make a small adjustment to the feed to get the bit closer to the grinding wheel and then do another sweep cut. After the first cut has been successfully made, you rotate the drill bit 180 degrees and make the cut for the other side. You should be able to do this without any adjustment or advancement of the bit, which ensures you get an even cut on both sides. I found it helpful to oil the pivot pin to ease the fixture movement when doing the sweeping movements. I also recommend user to make sure grinding wheel is ANSI approved, as it is generally understood any grinding on the side wheel is a “no no” and risks wheel disintegration. I found that with the minimal material removal I have recommended, very little wheel side stress was encountered but I took my time with bits over ½” and backed off in small increments to minimize heat which could damage the temper of the bit. The only thing this sharpener doesn’t do which the Drill Doctor will is to sharpen split point bits but you can still sharpen the primary cutting face with good results. I was a little skeptical when I first purchased this but became a full believer after careful setup and use. Most of the problems people have had a really because of the lack of instructions and use.

Modesto Feeney (verified owner) –

Just what I wanted, works fine

Pansy Reynolds (verified owner) –

Good and precise tool

Zora Braun (verified owner) –

Overall it works but lack of instructions on how you actually use it gives it only 3 stars for me. And even with some videos on you tube , it’s still difficult to set it up.

Robert Ernser (verified owner) –

This is a well construction precision attachment. It is better suited for a more skilled machinist rather than the average Joe. The instructions were not helpful at all. After searching several sites I was able to obtain an overview on how to set up the attachment. It must be mounted or clamped to a level surface to your grinder.If you sharpen a lot of bits, then it would be a good investment for you. My grinder came with a drill bit grinding guide and it is much easier to use.

Blake Stark (verified owner) –

I think this is well made and probably does a good job if you have the patience to set it up and take your time. It takes a bit of adjustment on each bit to get it set properly and you can make a mess of a drill bit very quickly if anything is out of alignment. My grinder is on a wooden workbench that is made pretty stout and it took some creativity to attach the base which is designed to be left in place. It would have been easier to move my grinder. I think I actually prefer the stand alone type of bit sharpener for my hobby workshop.

Kendall DuBuque (verified owner) –

Well machined precision. This jig produces accurate bevels and sharpened edges normally achieved only with more expensive electric bit grinders. Should you be unsure of the angle to grind, the instruction sheet clearly outlines proper adjustment. Despite its light weight and compact size, the castings are hefty and the milled parts well formed. In my shop, as with many, bench space is always at a premium. Because of this, any tool that is not used every day, is best broken down and stored away. The adjustable slot on the base of the unit allows simple attachment to the bench and easy removal. As this item is small and flat, it is easily stowed until needed again. Truly a useful tool at a reasonable cost.

Sim Lebsack (verified owner) –

Seemed to sharpen bits well. Mounted to a wood block to get the correct height so I could use the front of the 8″ grinding wheel with minimal curvature (instructions suggest using the side). Bits had tendency to wander after sharpening. Minor hand touch up near trailing edge of bit point fixed that.

Clemmie Schulist (verified owner) –

I mounted this on the side of my grinder. My grinder has 5″ wheel so I couldn’t mount it in front. Had to mount grinder on wood platform so that the axial would be level with tip of grinding attachment. A 7″ wheel grinder would be better but you should be able to improvise. Looks nice on work bench but an electric grinder would work just as well.

Myrtie Hintz (verified owner) –

The General Tools drill grinding attachment will sharpen up to three quarter inch sized bits; as opposed to my old bd sharpener that only went up to three-eighths inch bits. My grinder is mounted on a bench that allows this to be clamped in place as needed. Using the grinder’s light or another light shining from the side makes it easy to align the angle for each bit from one-eighths up to three-quarter inch. The guide sleeve, set screw, click-stop angle guide make adjustments quick and easy. There are five preset angles for various drill bits. One nice feature is that the base can be left mounted on the work stand and the tool removed. If your grindstone has a side-grinding ability the attachment can be mounted to the side of the grinder, otherwise it goes to the front.Site to obtain instructions (easier to read).https://www.generaltools.com/productdoc/index/downloadpdf/type/manuals/pdf/825-Instructions_GT_103007.pdf

Noe Franecki (verified owner) –

Fit and finish is a little lacking on this piece and to call it an attachment is going a little to far as it doesn’t actually attach to the sharpening wheel. To call it an accessory is more accurate. That said this accessory will do the job it intended and that is sharpen the tips of drill bits. If you need something that will sharpen the whole bit you will need something like the drill-bit doctor, if it still exists.

Sid Altenwerth (verified owner) –

Did a great job. Much better than I expected

Lexus Abshire (verified owner) –

To those complaining about the use of the word drill and not bit, professionals call drill bits “drills” and that is the proper term. That’s why they call the electric tool a “drill motor”. Hope this helps

Mia Gutkowski (verified owner) –

Imported version of general tools age old design drill bit sharpener. Ok, some people may not know you can sharpen and reuse bits. This is not for them. If you have a metal worling hobby and even a trade welding its a worthwhile accessory..Pros: affordable ..good finish and materials. cons: zero instructions. takes practice. You must permanently mount near a bench grinder and /or make a plate to mount to grinder itself. There is a great youtube video showing that. If you have a decent set of larger drills you would benefit a bunch frrom this guy.

Vita Wuckert (verified owner) –

Easy to assemble, making adjustments with grinder operating is a problem. Fine adjustment wheels for indexing bit must be tight and tray holder also has too be tightened good.