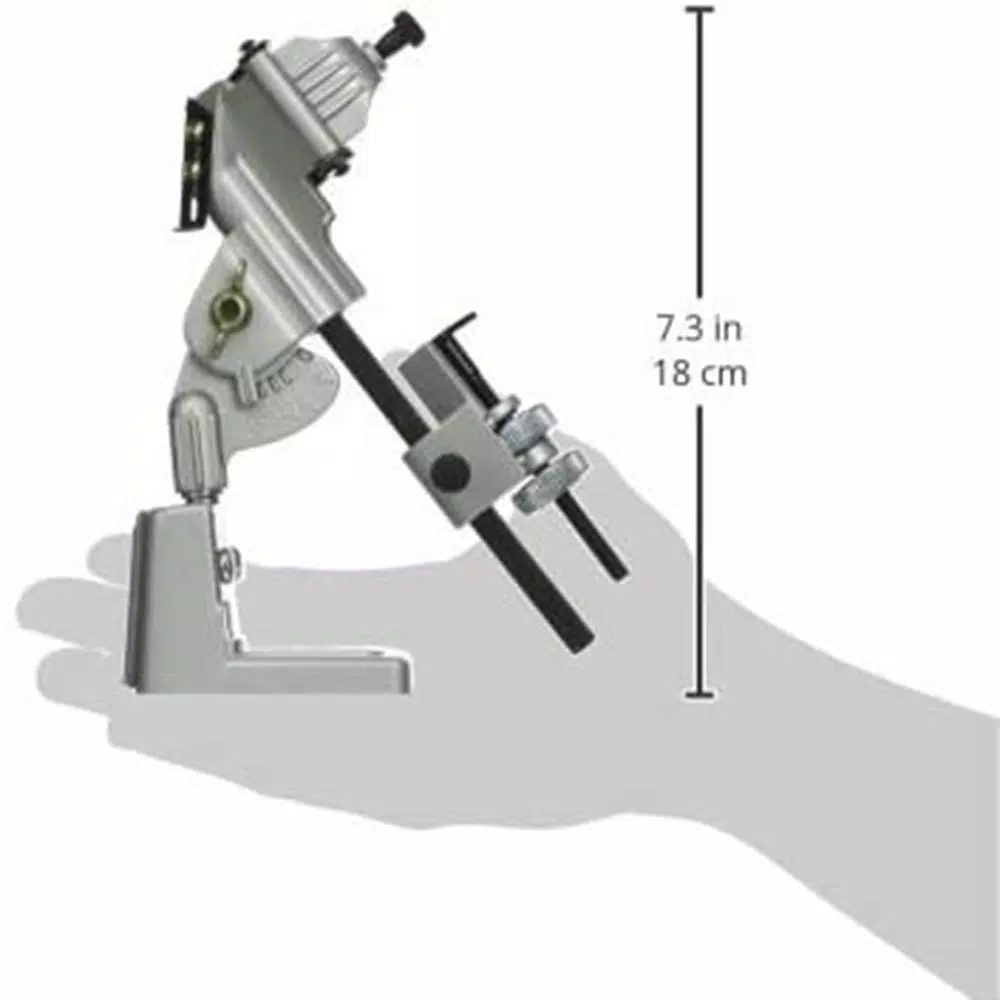

General Tools Drill Bit Sharpener & Grinding Tool Attachment

$23.72

Drill Grinding Attachment – Put new life into old drill bits, putting that brand new, out-of-the-box tip on them quickly and easily. Works great with larger, more expensive bits. Even works on countersinks.

In stock

Description

Extend the life of your drill bits with the General Original Drill Grinding Attachment. This durable tool quickly sharpens them back to factory tolerances. The angle adjustment gauge allows you to match the point angle of nearly any bit and even works on countersinks. Designed with a pivoting neck for simple grinding of both sides of the bit. For use with ANSI, OSHA and UL approved standard electric bench grinders or surface grinders.

- 3 in. alnico magnet with 50 lb. pull capacity

- Fits 1/8 to 3/4 in. bits

- Guide sleeve prevents screw wobble or disengaging from the bit, magnetic screwdriver bit tip for fastener retention

- Non-marking depth stop cap protects material surface

- Sliding, Spin-free depth stop/screw guide sleeve

- 1/4″ quick change compatible and impact hex shank

- Removable 1 in. driver bit

- Depth collar lock

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 1.8 lbs |

|---|---|

| Dimensions | 3.00 × 7.00 × 13.00 in |

| Color Family | Silver |

| Drill Attachment Product Type | Grinding Attachment |

| Material | Metal |

| Model | 825 |

| Power Tool Accessory Type | Other Accessory |

| Product Length (in.) | 7.38 |

| Tools Product Type | Power Tool |

Reviews (24)

24 reviews for General Tools Drill Bit Sharpener & Grinding Tool Attachment

Only logged in customers who have purchased this product may leave a review.

Related products

Drill Attachments

Model# RHA-50Drill Attachments

Model# 5354Drill Attachments

Model# 30602Drill Attachments

Model# 74068Drill Attachments

Model# 272701Drill Attachments

Model# 31874Drill Attachments

Model# 763415-9Drill Attachments

Model# HA3JAW

Davonte Orn (verified owner) –

no complaints…..it does what it’s advertised to do….simple twist drill bit sharpening for the home garage….not a professional device but adequate for occasional use…

Zackary Hansen (verified owner) –

Drill Grinding Attachmentby General ToolsPackaging Contents: Drill Grinding Attachment and instruction sheetDescription: It is not a drill attachment, but a drill bit holder. This device is a stand-alone mechanism to hold a drill bit at a specific angle so as to facilitate sharpening by placing the bit against a grinding wheel.There is a claim that it has a 3 in. alnico magnet with 50 lb. pull capacity. I never found such a thing.It claims to fit bits sizes 1/8 to 3/4 inch and is made in the USA.No hold down screws included.Usage: The instructions are simply a photocopied piece of paper with poor resolution. I found them to be difficult to follow because they did not have a listing of explanations for the part letters. Do not use the enclosed instructions.By calling General Tool at 800-697-8665, you may request they e-mail you the correct user guide. It is different than the one enclosed with the tool.Further, the tech support people recommend looking at the YouTube videos on the subject. Otherwise you will have conflicting visuals from various pictures.Keep in mind that the naming is incorrect. Remember that whenever it mentions “drill”, it actually means “drill bit”.One must first understand that using this device requires it to be fastened down next to a grinding wheel and perpendicular to it. I just clamped mine in place.Secondarily, the user must realize that the device holds the bit in place to sharpen one side at a time. To do the second side requires the bit to be rotated 180 degrees. That appears to be the purpose for the lip rest used as a rotational stop.There is a chart in the instructions. It gives the proper angle, depending on material to be drilled or the original angle of the bit set you have, and it gives the amount of distance the bit should extend past the lip rest point.I liked that the detents on the angle adjustment scale matched the angle adjustment indicator to lock them together. The angle will not change while using it.I didn’t at first like that the base can be twisted from the top portion, which can be viewed as changing the alignment of the bit and grinding wheel. However, there is a reason for that. It turns out that the bit surface is curved and so the necessity of swinging the bit back and forth on the grinding wheel maintains that curve.I will say at this point two important points. First, the bits can be sharpened very well. Second, the device is finicky to use.There are numerous adjustments to be maintained, and some include locking in place. Therefore, every time you wish to move the bit forward, it requires some fiddling with it. Also, if you desire to sharpen both faces the same, it is necessary to cut one face and then, without any further adjustment, turn the bit 180 degrees to do the other side. Only then can you advance the bit to cut more if necessary. If this is not done, the two sides will be cut to different lengths.Overall Thoughts:Good price, if you don’t have the money for an automatic machine.

Evangeline Harris (verified owner) –

I think it works just fine for homeowner use!

Caden Kirlin (verified owner) –

This drill fixture has good potential, but the design should be changed to leverage its true capability. 1) The overall fixture design is too tall, as this height lowers mechanical stiffness. This lack of stiffness gives a poorer ground finish on the drill bit. 2) The fixture as designed is really only good for one ground angle, such as 68 degrees per side. Changing the ground angle changes the pivot geometry enough to cause issues while attempting other ground bit angles.I used a major portion of this fixture to creat a much shorter and more robust drill bit grinding fixture, and it works pretty good, even on bits down to .125 inch. But even then care has to be taken not to grind one side much more than the other.