General Tools X1 Professional Face Frame System

$87.60

Acquire a modish and excellent addition to complete your tough tasks comfortably in the jobsite by choosing this General Tools X Face Frame System.

In stock

Description

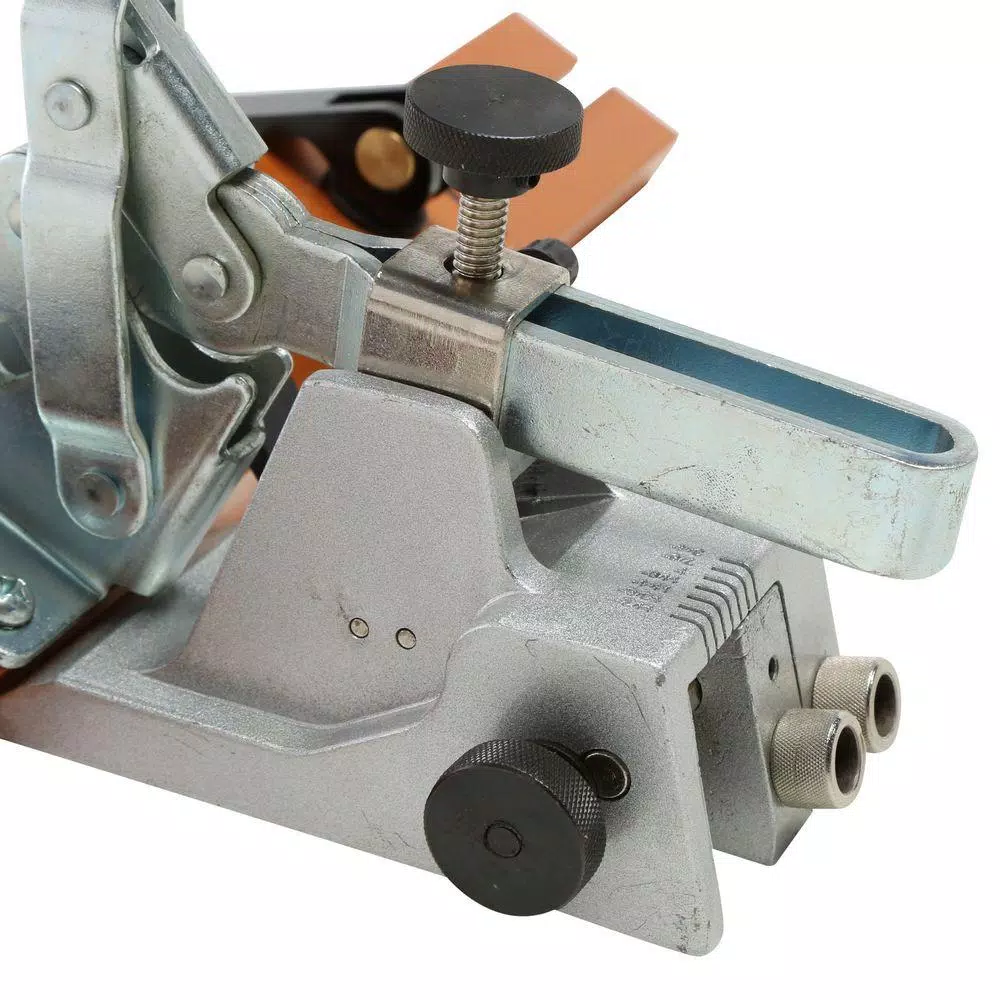

For nearly 85 years General Tools has grown to become the recognized industry leader for specialty hand tools and instruments. The all-new Professional Face Frame Jig System from General Tools and Instruments allows you to create a professional production setup in just minutes for fast, precise fabrication and assembly of cabinet face frames and doors. With this system, wood frame and door components can be aligned, securely clamped, bored for pocket holes and screwed together in 1 operation. X1 Kit includes: one Face Frame Jigs one 20 in. L Face Frame Jig HD T-Track; 2 Face Frame Jig Stops; one Face Frame Jig Step-Drill with stop collar; 1 Face Frame Jig Screwdriver Bit; and 100 fines thread Face Frame Jig screws.

- Assemble professional quality face frame and cabinet doors using the new face frame joining system

- Align and clamp frame components, screw pocket holes and assemble all in 1 setup

- Accommodates stock from 1-1/4 in. to 2-1/2 in. W and thickness adjustment from 3/4 in. to 1 in.

- Pocket hole spacing adjustment from 3/4 in. to 1-1/2 in. for maximum joint strength

- Includes 3/8 in. step-drill with stop collar, #2SQ driver bit and face frame fasteners

- X1 kit includes: 1 face frame jigs 1 20 in. L face frame jig heavy duty T-track; 2 face frame jig stops; 1 face frame jig step-drill with stop collar; 1 face frame jig screwdriver bit; and 100 fine thread face frame jig screws

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 0.3 lbs |

|---|---|

| Dimensions | 6.00 × 8.00 × 21.00 in |

| Individual/Set | Set |

| Jig type | Drill |

| Material | Aluminum |

| Maximum stock size (in.) | 2.5 |

| Minimum stock size (in.) | 1.25 |

| Model | 8561 |

| Number of Pieces | 106 |

| Power Tool Accessory Type | Jig |

| Product Length (in.) | 20 |

| Tools Product Type | Power Tool |

Reviews (5)

5 reviews for General Tools X1 Professional Face Frame System

Only logged in customers who have purchased this product may leave a review.

Related products

Cutting Tools

Model# M5RLCutting Tools

Model# E5Cutting Tools

Wiss 9-3/4 in. Compound Action Straight and Right Cut Aviation Snips

Model# M2RSCutting Tools

Model# M6RSCutting Tools

Model# 20-220Cutting Tools

Model# 63324Cutting Tools

Model# 8501HCutting Tools

Stanley 27.75 in. Adjustable Angle Clamping Miter Box with 22 in. Saw

Model# 20-800

Rafael Batz (verified owner) –

The jig works well as expected from General Tool. I have three of these jigs and use them regularly with very little problems. We had one issue with one clamp and it was promptly taken care of by General Tool.

Grant Raynor (verified owner) –

The General pocket hole jig is the best purchase a cabinet maker could make! It not only makes joints a snap, it enables production line type work. Speeding up production of face frames, doors, and any other application where invisible fasteners are desired. With or without glue! Fifteen minute set-up time and you’re off to making joints that hold up and look nice!

Cielo Towne (verified owner) –

This face frame jig is meant to make life easier for a production style face framing setup, but I have some big reservations about quality and longevity.The main rail mounts to a workbench with both horizontal and vertical screws, which holds it in place very firmly. However, the included screws for attaching it are drywall screws, which have a much lower shear strength than regular wood screws.Also included is the stepped drill bit, a stop collar, a square drive extended bit, 100 self-tapping screws, and two allen wrenches for set screw adjustment. I wasn’t too impressed with the quality of the square drive bit. Its runout was surprisingly extreme, which I verified both by placing it on the work bench and rolling it, and by chucking it up in my cordless drill and watching it wobble as it spun. I was also a little annoyed that the kit uses two different sized set screws. There’s no reason they couldn’t have been made the same size, so I’d only have to keep track of one allen wrench.The main clamp and drill guide is attached to the rail with a T-track system so it can slide back and forth into the proper place and then clamp down. There are also two stop blocks for the jig, which limit its travel on the rail. However, I found it easier to just leave the jig in place and slide my workpieces back and forth to line them up. Maybe a full-scale production setup could make a better use of that feature. The rail clamps are a little finicky, and I found that the adjustment screws were coarse enough that they only clamped down fully in a 10-15° arc. This can cause problems when that arc leaves the clamp lever in the way of the hold down or the work piece though.The drill guide itself is made of either cast aluminum or magnesium. Either way, I would have liked to see some steel inserts for the bores of the guides. You can see in my video that I ended up with about half sawdust and half metal shavings after drilling two holes. Maybe it will get better after a “break-in” period, but that just means there’s even more slop that’s developed between the bore and the drill bit.The stock thickness this can handle is only from 3/4″ to 1″. I was hoping it could handle up to 1-1/2″ stock, but unfortunately it wouldn’t fit when I tried. There’s also no provision for dust collection with this kit. Seems like something meant for a production setup should have allowed for that.On the plus side, the clamping feature seems to work pretty well, and it’s nice to be able to clamp, drill, and fasten all without rearranging the work piece. Overall I wanted to like this kit, but there are just too many shortcomings in its design and quality for me to recommend it – there are much better options for about the same price.

Kiley Cruickshank (verified owner) –

Don’t let the price fool you, this is an awesome face frame jig for the price.The jig slide is made of extruded aluminum with a gold/orange coating.Out of the box, you have everything you need to get up and running, including a face frame jig screwdriver bit, jig step-drill (with stop collar), and even 100 fines thread face frame jig screws. Even the allen wrenches are provided.The 20 inch rail screws to you workbench (screws supplied)A simple thumb screw adjusts the pocket guides from 3/4 in to 1-1/2 in (with , and another thumb screw allows you to adjust for 1-1/4 in. to 2-1/2 stock.Two guide jig stops are included, which increase speed when creating like pieces.I found no slack or movement when the jig was clamped down.The kit does not include directions, but for those new to creating cabinet face frames and doors a simple search online shows instructional videos.

Wallace D’Amore (verified owner) –

A little bit loosey goose on the clamp. Would like it to be more solid. Not bad for a handyman though