Makita 15 Amp 14 in. Corded SJS Electric Angle Cutter with AC/DC Switch

$629.00

Provide a powerful concrete cutting solution by using this Makita SJS Electric Angle Cutter. Ideal for edge-to-edge cut.

In stock

Description

Ideal for cutting concrete and edge-to-edge cuts, the Electric Angle Cutter offers durability and power for precision performance. This angle cutter features a 14-inch diamond blade and comes powered by a 15-Amp motor with 3,500 RPM to meet the most demanding jobs. An adjustable, removable base adds versatility to projects for closer cutting action and allows for cuts up to 5-in. deep, while guide wheels on the tool guard ensure smoother cuts. The angle cutter is easy to use with a built-in vacuum attachment port and rubber shield to reduce dust and debris from accumulating while you work. A rubberized wrap-around handle increases user comfort.

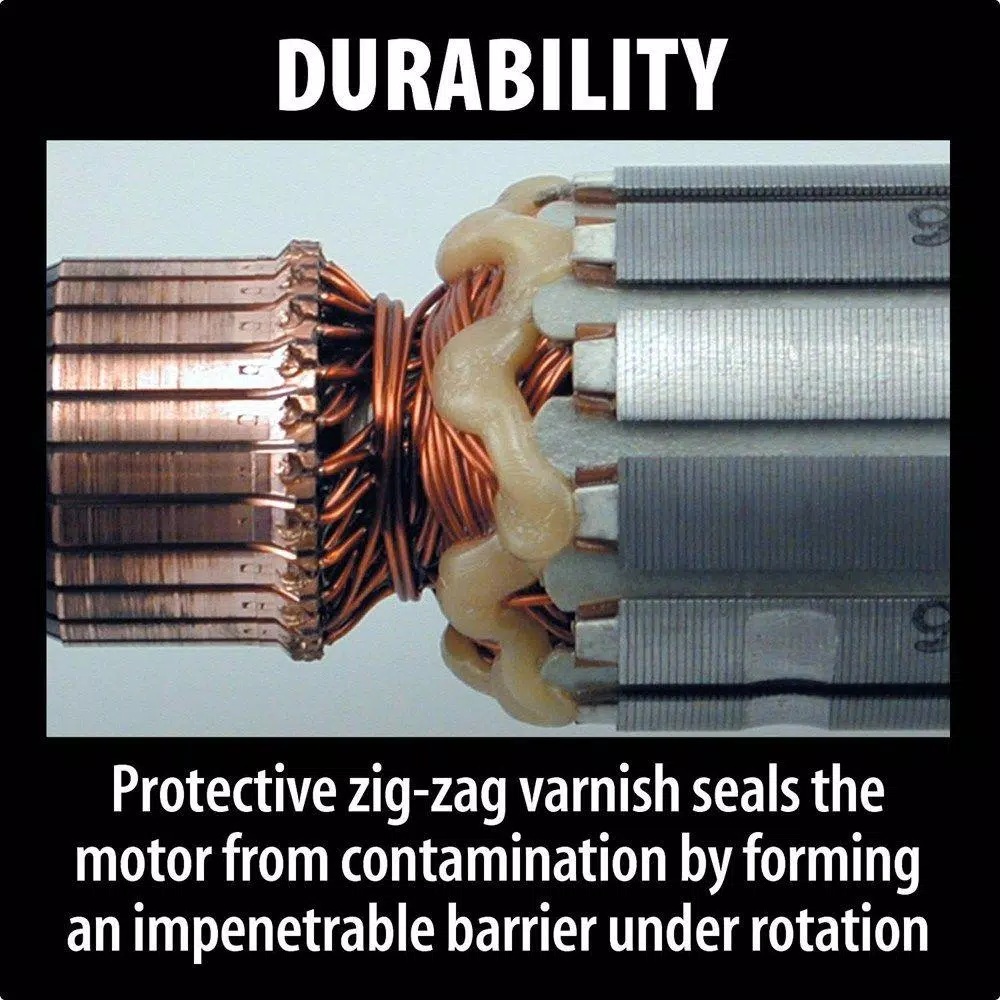

- Super joint system – SJS technology helps prevent gear damage

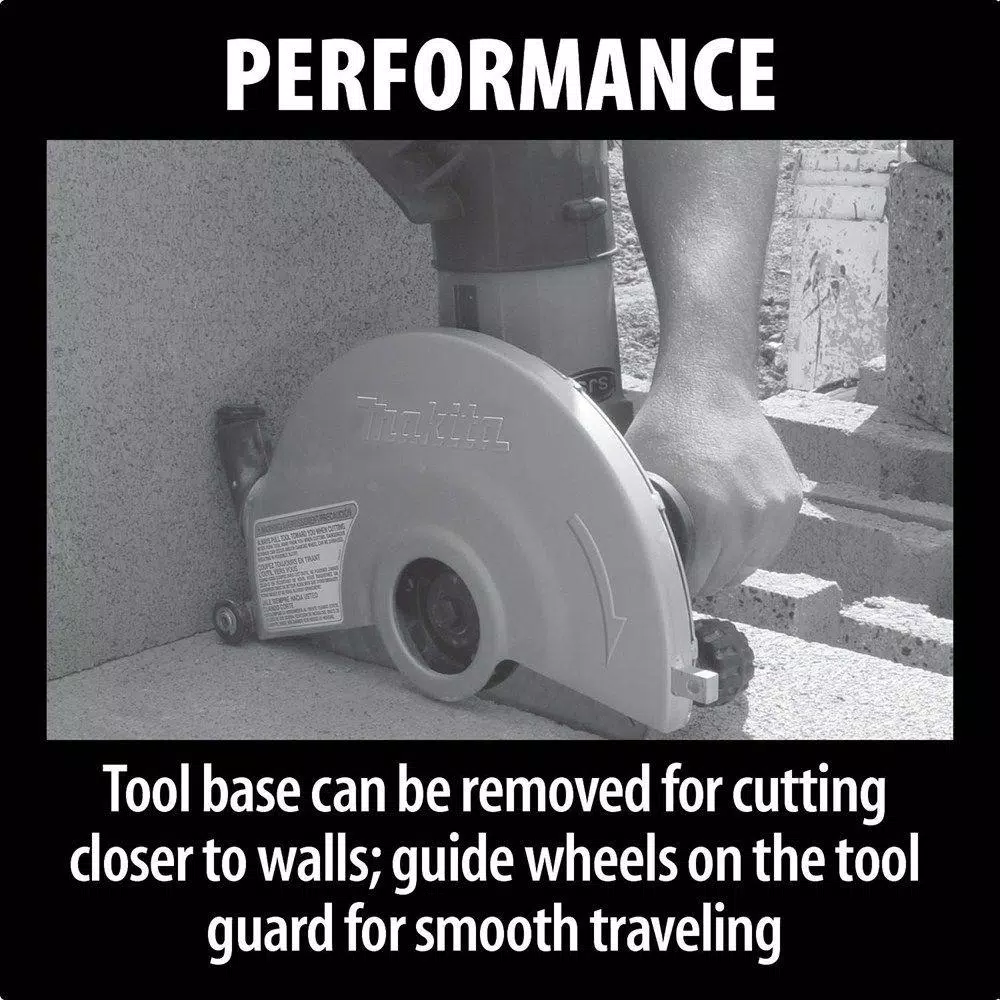

- Removable base for a closer edge-to-edge cut

- Rubberized wraparound handle for increased comfort and control

- Built-in vacuum attachment port and rubber shield reduces dust and debris

- Powerful 15-Amp motor delivers 3,500 RPM for the most demanding applications

- AC/DC switch for use with alternative power source

- Rubber shield helps keep debris away from operator and from entering the motor

- Tool base adjusts allowing up to 5 in. cutting depth; best for cutting split face block when building retaining walls

- Guide wheels on the tool guard ensure smooth traveling of tool over surface material when base is removed for cutting closer to walls

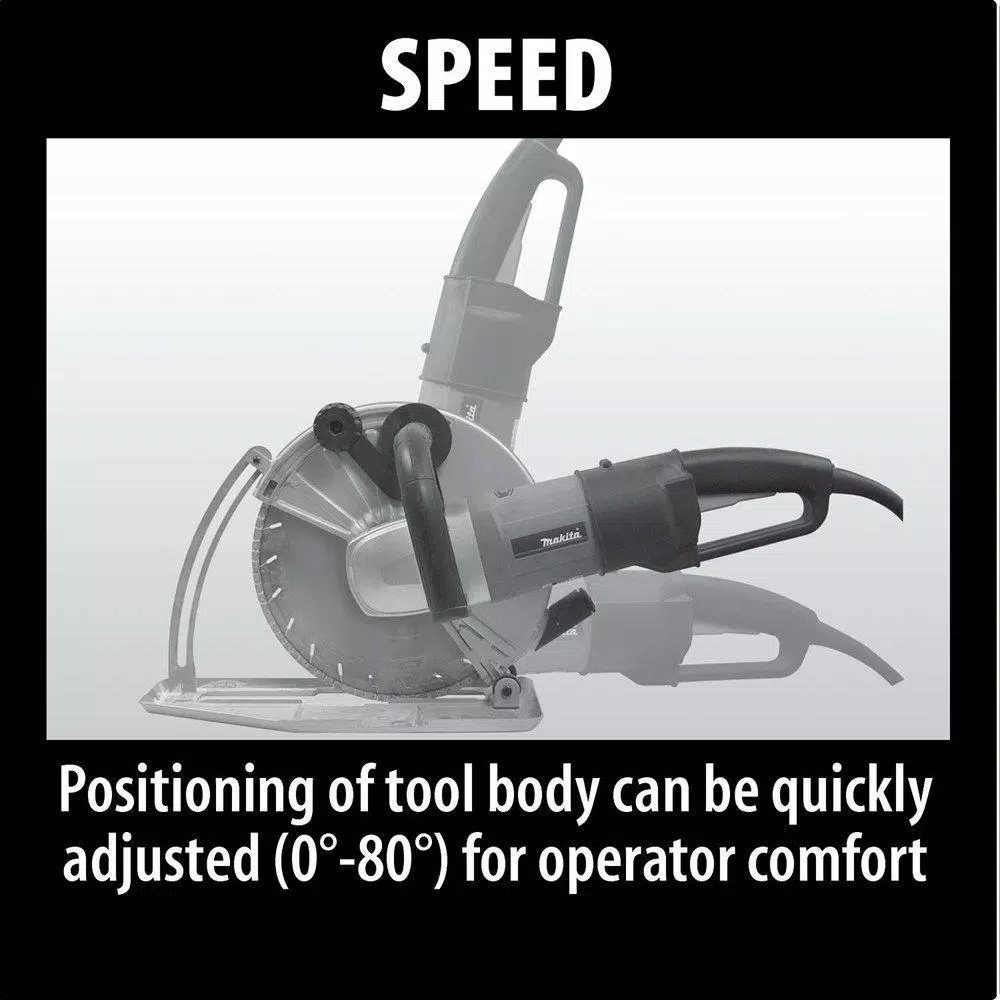

- Positioning of the tool body can be adjusted (0 Degree -80 Degree ) for operator comfort; operates independently of cutting depth for convenience and efficiency

- Base has front and rear cutting guides for increased accuracy

- All-ball bearing construction for longer tool life

- Externally accessible brushes for greater serviceability

- Lock-on button for continuous operation

- 1 year warranty

- Includes: socket wrench 17 (782210-8)

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 24.2 lbs |

|---|---|

| Dimensions | 17.10 × 32.65 × 10.60 in |

| Assembled Depth (in.) | 26.5 in |

| Maximum Cutting Thickness (in.) | 5 |

| Tool weight (lb.) | 26.5 |

| Start Type | Electric |

| Saw Drive Type | Worm Drive |

| Power Tool Features | Depth Adjustment |

| PT Horsepower (Hp) | 0 |

| Model | 4114 |

| Included Accessories | Hand Tools |

| Assembled Height (in.) | 10.56 in |

| Cuts Through | Stone |

| Construction Material | Plastic |

| Condition | New |

| Color Family | Silver |

| Blade Diameter (in.) | 14 |

| Blade Diameter | 14 |

| Assembled Width (in.) | 15.95 in |

| Tools Product Type | Power Tool |

Reviews (15)

15 reviews for Makita 15 Amp 14 in. Corded SJS Electric Angle Cutter with AC/DC Switch

Only logged in customers who have purchased this product may leave a review.

Related products

Saws

Model# 6955-20Saws

Model# 6480-20Saws

Model# DW331KSaws

Model# DW304PKSaws

Model# D28715

Darlene Rau (verified owner) –

Saw was easy for me to handle while cutting concrete capstones

Laila Bartell (verified owner) –

Very Good

Leonor Towne (verified owner) –

The saw performed as I expected.

Lavada Bartell (verified owner) –

This saw is well worth the money. Tired of renting? Here is your solution!

Napoleon Sawayn (verified owner) –

I like to work with the Makita tools is one of best brands and smooth to handle and durable

Norwood Nolan (verified owner) –

Thumbs up I like it

Malachi Cormier (verified owner) –

Nice for indoor cutting with strong vacuum and adding little bit of water while cutting…

Ottilie Pagac (verified owner) –

Worked as expected. Can not locate the nipple for the vacuum though.

Sherwood Quitzon (verified owner) –

so far. so good

Cara Carter (verified owner) –

After renting so many wet concrete saws, we decided to buy one. We purchased this saw for the fact that it had a vacuum port on it. We were cutting interior concrete for a conduit run to an island. We use many floor grinders and other tools with our vacuum system with little to no dust. This tool cut like any other concrete saw, very well. However, thank god we put up a plastic containment barrier in the area we were working in. The saw did not perform as expected, in the fact that none of the dust made into the vacuum system. What’s the point of adding a vacuum port if it doesn’t work. If we could return the saw, we would. Then, purchase the wet version and deal with the slurry mess. We own several large expensive Makita demo tools and this one is extremely disappointing. Do not buy this saw if you are trying to keep the dust down.

Reanna Schultz (verified owner) –

Super equipment. But not 3 years warranty available at Home Depot.

Bradly Trantow (verified owner) –

I like to work with the Makita tools is one of best brands and smooth to handle and durable

Davon Bins (verified owner) –

Performance was acceptable. Slower than a gas saw but needed to cut a 4” slab inside the house. Vacuum kept a lot of the dust down. Take 1” depth bites max or it slows way down. Always pull saw towards you. Straight lines a must or blade will bind. Very satisfied overall.

Rosemary Block (verified owner) –

it is a little slow ,but if you are no’t in rush ,work fantastically.I cut a 10″ foundation with out any problems ,it is lighter and smaller then a gas machine, excellent for medium project.

Paxton Fahey (verified owner) –

Good saw for what it is intended to do. It is not a gasoline powered saw and will not have that kind of power.Pros: electric motor is plenty powerful if used properly. That is, follow the instructions and cut about 2″ deep or less. Make multiple passes for deeper cuts.Cons: The angle adjustment bracket is flimsy so the blade does not stay at 90 degrees to the cutting base. I have to adjust the position of the motor using the “wheel guard” adjustment depending on how I have the depth of the cut adjusted to keep the base at exactly 90 degrees to the cutting blade. Since the saw is a pull saw, that is you start the cut with the rear of the blade and putt it towards you (the operator), it s hard to get it accurately aligned to the marked cutting line. It is difficult to see your line on the block you are cutting once the saw is placed into position. Also, because it is a pull saw when cuts are first started there is very little of the saw base that rests on the cutting surface so the alignment is hard to see and balancing the saw on such a small area is tricky. Then, when you activate the power the saw has a lot of torque and gives a big kick that tends to move it and cause misalignment. So, I start cuts using a plunge cut technique. I align the notch on the back of the saw with the desired cutting line about 3 to 4 inches from the edge of the start of the cut on the block I am cutting. Then to further align it, I position the blade over the cutting line about an 1/8 inch above the surface while keeping the rear base on the back of the saw on the surface of the block to be cut. Also, I make sure when the initial plunge cut is complete that the front edge of the saw blade will be at or beyond the starting point of the cut so I don’t have to push it forward to cat all the material that needs to be cut. I start the saw, absorb the kick, check and adjust the blade position by moving the saw back to the right position. I start the cut by slowly pivoting it down, using the back of the base as the pivot point, until the bade engages. I carefully plunge it into the material to be cut. Once the entire base is flush and solid against the surface I then continue the cut by pulling the saw towards me. Note when I do this I have the depth of the cut set at about 1.5 inches so the plunge cut is not too deep. I saw some complaints about the vacuum attachment and its inability to capture the dust. I am using it outside so I just let the dust fly, and yes it does make quite a cloud.