Milescraft Rotary Tool Drill Press Stand for Woodworking and Jewelry Making

$38.65

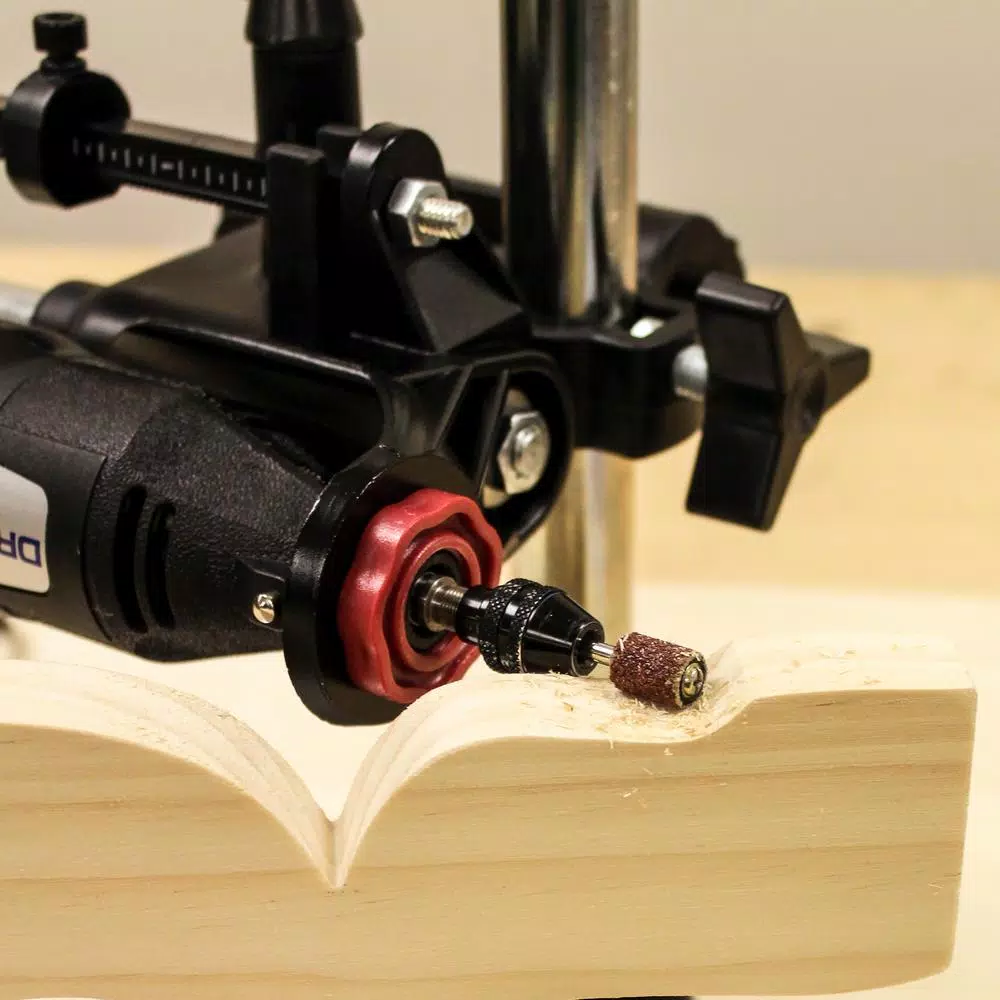

Elevate Your Rotary Tool’s Performance to “Machine Tool” Standards with the ToolStand! Transform a handheld rotary device into a precision drilling machine with the rotary ToolStand. This stand is compatible with most Dremel-style rotary tools. Rack and pinion gearing allows smooth controlled plunge. Scale with depth stop allows depth control and precise repeatability. Sturdy cast aluminum base provides sturdy work area. Strong 13.5 inch metal tube allows drilling of objects up to 5 inches in height. Lock rotary tool in horizontal position for hands free sanding or polishing.

In stock

Maxine Dickinson (verified owner) –

Pleasantly surprised with the high quality of this amazingly inexpensive tool. I mounted my dremel horizontally using two 10 inch mini-bungee cords stretched tightly around the tool and mount. I will use this often modifying and reengineering substandard reproduction motorcycle parts.

Vince Prosacco (verified owner) –

The assembly instruction step by step easy to follow, well made my wife uses it for crafting and jewelry making, worked perfectly with a cordless Drexel tool

Mario Ferry (verified owner) –

Easy to set up and use, reminiscent of the old Dremel Model 212 Type II press I used to own, but with a few extra features. Dremel 395 tool works great in it.

Hailee Barrows (verified owner) –

This is a nice thing to have and for the money it’s pretty outstanding. Good quality and performs well for the purposes advertised. Would definitely recommend!

Geovanny King (verified owner) –

It is shorter and better balanced and less expensive than the Dremel Workstation.

Sydnee Walsh (verified owner) –

Good inexpensive tool to use for crafts, hobbies and precise milling work.

Colin DuBuque (verified owner) –

I used to successfully drill out tac-welds on a Lithium-ion battery pack terminal header. Would have been better if the drill guide had been more rigid.

Stephany Lynch (verified owner) –

Had to turn my Black & Decker rotary tool sideways to fit in the drill press, but it works fine otherwise. It does have a little play when lowering the handle, but I have used it to drill holes in glass, ceramics and pottery with nice results. The cap on the pole does not fit tight so I have to make sure that I don’t lose it when traveling with the stand. Nice hobby tool.

Freida Hammes (verified owner) –

It works well as a drill press but took me awhile to figure out what to tighten to keep the drill from wobbling on the downward stroke

Seamus Welch (verified owner) –

works fine only used once but worked ok

Alvina Cremin (verified owner) –

This is a good, very light-duty drill press. It is quite rigid, especially in comparison to the near-identical Dremel product. Dremel’s work center does allow you to hold the rotary Dremel Tool at an angle, but it does not have the kind of rigidity that this Drill Press has. Where this unit has cast metal and very rigid plastic, the other has flexible pieces of thin plastic.On the Dremel Work Station, I tried drilling some 6061 aluminum, which is a pretty soft alloy, by the way, but my drill just walked all over the place. The drill was plenty sharp, but the work station just flexed too much.I am quite confident that this tool won’t be like that.Somebody thought that the tripodal base is unstable, but there is no more stable an arrangement than a tripod. As far as it’s instability when the rotary tool is turned sideways, well that is the same for all of these small drill presses. Unless they are clamped down, they are unstable.So, clamp it down.The ToolStand is a light-duty item, but still quite rigid. I am very satisfied with it and would recommend it to anyone else.

Terrill Streich (verified owner) –

This stand is meant to hold a Dremel type tool so you can use the tool like a drill press or to hold the tool so you can move the work with both hands. I found it to fill the bill as long as the project is very light duty. There is an excessive amount of play in the mechanism for any tight repeatability. There are two screws to lock the unit in position but they require a screwdriver. They should be replaced with thumb screws.I was going to use this stand to fashion a mini vertical mill but it is so light that any side load will just bend or twist the unit. Replacing the thin vertical column with a heavy pipe will help with rigidity but then the base becomes useless.This device is OK to drill holes in Printed Circuit Boards or if you have a pilot hole to guide the drill but do not rely on it to give you repeatable results.

Brenden Hermiston (verified owner) –

The drill stand was easy to assemble and well made. My Dremel drill fit nicely in the fixture. The drill stand was a casting that was light weight and of high quality.

Myrtle Jacobson (verified owner) –

It was not too difficult to assemble, but I would suggest adding instructions on how to lubricate the gears.Also, I was unable to locate a vise to hold my work piece that would also fit into the slots on the base of the drill press

Nichole McLaughlin (verified owner) –

It is shorter and better balanced and less expensive than the Dremel Workstation.

Kennith Pagac (verified owner) –

Recognizing that the M1097 Milescraft rotary drill press stand is not a precision machine tool, it still is worth considering for hobby use. Its low price is closer to what one might expect to pay for a toy, but overall the materials, quality and functionality is pretty good.Pros:Low priceEasy assembly using a Phillips screwdriver and small adjustable wrench or pliersAssembly instructions are fairly good, but the photos are a little fuzzyLooks like it will accommodate a variety of models and sizes of rotary toolsAllows mounting a rotary tool horizontal (90 degrees) for polishing, cutting, etc.Light weight but fairly sturdy. Easy to move from bench to storage.Cons:The pilot feed lever hits the depth stop set screw. This is not a serious problem, but its annoying. It simply needs needs a slightly shorter set screw.The pilot feed lever operation is a little jerky. The spring drags and pops.The spring cover is a thin metal plate secured by only one screw. This cover came warped and dented straight out of the box.There is no provision for clamping the work. One will probably need to improvise. I use blue painters tape for holding small circuit boards as shown in photos.This works OK for drilling a few holes. The base has four slots part way cut in at 45 degrees – like an “X” without the crossing point. I have not found any machine or milling vise that will mount on the base. The slots are large enough for a 5/16” – 3/8”carriage bolt, but, why?The rotary tool is mounted cantilever on its nose. This allows a slight wobble when contacting the drilling surface. The illustration on the shipping box shows a strap providing lateral support, but it was not included with my unit.To turn the tool 90 degrees you must completely remove the assembly from the column, turn the assembly 90 degrees and reinstall it on the column. The cantilever mounting causes more instability when the tool is 90 degrees. Furthermore, the whole thing is off balance and it tends to fall counter clockwise unless the base is anchored securely.Overall, the design needs improvement, but the unit works OK for the price.

Dorcas Nitzsche (verified owner) –

Nice tool does a great job, easy to assemble and fair priced.