Milwaukee 12 in. 7 TPI TORCH Nitrus Carbide Teeth Metal Cutting SAWZALL Reciprocating Saw Blade

$27.99

Make your cutting work more easier by choosing this Milwaukee TORCH Nitrus Carbide Teeth Metal Cutting SAWZALL Reciprocating Saw Blade

In stock

Description

The Milwaukee 12 in. 7TPI The TORCH with NITRUS CARBIDE SAWZALL Blade for CAST IRON and other thick metals is the next generation of carbide teeth technology. This SAWZALL blade with NITRUS CARBIDE teeth cuts longer, cuts more and cuts faster than traditional carbide teeth products on the market. Milwaukee NITRUS CARBIDE technology eliminates the tradeoff between blade life and speed of cut compared to traditional carbide teeth blades. The blade delivers 3X the life of existing carbide reciprocating saw blades to continuously make the toughest cast iron removals on the job. The TORCH SAWZALL blade with NITRUS CARBIDE cuts the thickest metals like cast iron and soil pipe. The unique carbide blend outperforms standard carbide teeth blades in common thick metals.

- Carbide teeth for 50x life in thick metal

- Carbide teeth for longer life and greater versatility

- Cuts cast iron, stainless steel and high strength alloys

- Fast in cast iron

- Offered in 1-pack, 3-pack, 5-pack and select 25-pack

- Up to 70% larger gullets for easy chip ejection

Additional information

| Weight | 0.2 lbs |

|---|---|

| Dimensions | 0.48 × 2.00 × 14.70 in |

| Blade Length (in.) | 12 |

| Blade Width (in.) | 1/20" |

| Color Family | Red |

| Demolition | Yes |

| Material Cut | Metal |

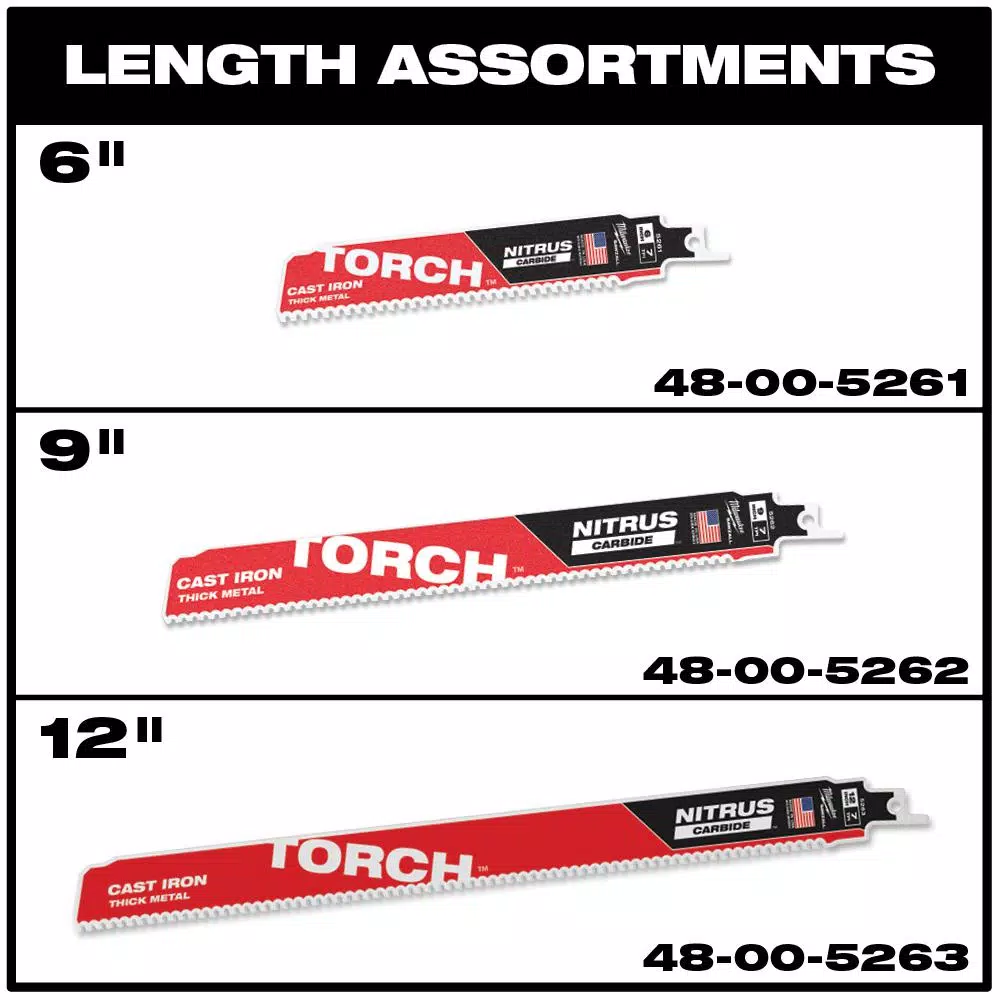

| Model | 48-00-5263 |

| Number in Package | 3 |

| Number of Teeth | 84 |

| Power Tool Accessory Type | Reciprocating Saw Blade |

| Saw Blade Material | Carbide |

| Teeth Per Inch | 7 |

| Tools Product Type | Power Tool |

Reviews (93)

93 reviews for Milwaukee 12 in. 7 TPI TORCH Nitrus Carbide Teeth Metal Cutting SAWZALL Reciprocating Saw Blade

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

Milwaukee 9 in. 14 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5187Saw Blades

Model# D1080XSaw Blades

Milwaukee 6 in. 24 Teeth per in. Thin Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5186Saw Blades

Milwaukee 12 in. 5 Teeth per in. Wood Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5037Saw Blades

DEWALT 8 in. 18 Teeth per in. Demolition Reciprocating Saw Blade (5-Pack)

Model# DW4821Saw Blades

Model# 48-00-8788Saw Blades

Milwaukee 9 in. 18 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5188Saw Blades

Model# DW3106

Lacy DuBuque (verified owner) –

I’m a retired engineer, and I remember when the industry introduced a “Nitriding” heat treatment process for hydraulic cylinder rods. That was a case hardening process which diffuses nitrogen into the surface. It provided some degree of corrosion resistance, plus a very hard surface that was a couple thousands of an inch deep. I’m fairly certain this is the process Milwaukee is using on these blades. Typically, when we hear the word “carbide blades”, we expect to see hard carbide inserts brazed to the teeth. This is not how these blades are made. I suspect “Nitrus Carbide” is a marketing play on words. I’m not saying this is a poor application for this process. Actually, I think it’s a good process for these blades. Occasionally, I have bent Saws-all blades, and have been able to straighten them out with a couple plyers. I haven’t bent any of these yet, but I suspect they will have similar ductility (good). Blade thickness appears to be standard (approximately 0.060”). The only negative comment is marketing, calling this carbide.

Abe Walker (verified owner) –

These blades are great. I got them mainly to cut some fairly thick metal fence posts, and they’ve been very effective; the phrase “hot knife through butter” comes to mind. I haven’t tried to cut anything heavier, but based on their performance so far, I have faith that they could handle it. They are a little pricey, but if you need to cut heavy gauge metal, these blades are well worth it.

Ada Spencer (verified owner) –

I had an old cast iron pipe that had dulled several metal cutting blades. This blade really impressed me, it cut thru the pipe with such ease that I would recommend this blade for use on this type of metal.

Maida Purdy (verified owner) –

The MILWAUKEE 9 IN. 7 TPI TORCH NITRUS CARBIDE TEETH METAL CUTTING SAWZALL RECIPROCATING SAW BLADE is a nice addition to my sawzall kit. I chose this product to see how it will perform when needed. I take my sawzall kit to the dirt track for needed immediate repairs if for any reason we have minor damage. I can just tell by looking at the durability of the blade that I feel it will outperform a standard sawzall blade. You can’t go wrong with Milwaukee products!!

Shany Skiles (verified owner) –

Really good blades. I’m use to using Diablo but these new milwaukee blades are definitely up there. I cut through galvanized steel and some really old cast iron pipe. Definitely got the job done and for the cast iron it definitely cut but it was a large diameter pipe so I had to use the longer blade. But these blades are definitely wreckers. The life of the blade holds up pretty good and so far I’m still on the first one. The carbide teeth are still there and feel pretty sharp. I literally cut through cast iron in a confined space with the fuel hackzall. It’s cut through every metal I’ve used it so far for. Definitely recommend it better it with the sawzall so control is better because the teeth have some serious bite.

Asha Bayer (verified owner) –

I have a number of Milwaukee products which have performed exceptionally well and these saw blades are no exception. I had some plumbing work which needed to be done. I used this blade with my Milwaukee Sawzall to saw through the metal pipes and it cut very easily and quickly. I like the fact that it comes in a three pack so that I have some extras. I highly recommend these blades.

Davion Upton (verified owner) –

Milwaukee sawzall blades are undoubtedly 1 of the best reciprocating saw blades on the market and this blade surpasses the original sawzall blades that Milwaukee makes and is superior in a lot of noticeable ways when using the blade on cast iron as what this blade is designed for use on. It is best when using this blade to use the original Milwaukee Sawzall as this blade is designed for that tool and will give the best results however this blade will work on any reciprocating saw.

Flavio Fay (verified owner) –

Tough blades that are capable of getting through cast iron and thick metal quite easily. I used it on an older drain pipe that was buried and it did great. I also tried it on a couple nails that I needed to cut and they worked through them with ease.The carbide teeth are long lasting, showing little signs of wear after a couple major cut jobs. The value of the 3 pack is great for homeowners and contractors alike. Great for demo, plumbing or drainage projects where you need a tough blade.

Doris Kozey (verified owner) –

These carbide reciprocating saw blades from Milwaukee are just the thing to cut through tough metal. I recently used one on my last project which involved cutting to length some galvanized electrical conduit pipes. The teeth were sharp and cut through the metal smoothly but not so fast that they grabbed too much material. My other Milwaukee bits and blades have off held up well so I expect the same from these. Good quality tools.

Nico Herman (verified owner) –

Milwaukee never disapoints, never. Their quality control is the best. I used this with my Milwaukee 28V cordless, and let me tell you, these teeth grip, seriously grip. Make cutting up a motorcycle frame was a task easily accomplished…………………………………………………………………………………………………Oh and packed well.

Kellen Powlowski (verified owner) –

Milwaukee metal cutting blades for cast iron and other thick metals cut faster than traditional carbide teeth products that are available. These blades cut through black metal pipe as a regular blade would cut through wood.The blade delivers three times the life of existing carbide toothed reciprocating saw blades and hardly showed any wear after the trial cut. these have a universal tang so that they can be used in all reciprocating saws. The TORCH SAWZALL cuts the thickest metal such as cast iron and soil pipe. I cut 3/4″ diameter 72 inch long steel black steel pipe to make two three foot pipe clamps.The cut took less than ten seconds; took longer to set up than do the actual cut.

Chaya Thompson (verified owner) –

Was easy to use and strong

Brian Rodriguez (verified owner) –

These blades are truly engineered to cut fast. I filmed a short video of myself cutting 2 inch unistrut. These Nitrus blades went through in 5 seconds. It probably would have cut a second faster had I secured it better. With the factory closest to me shut down to Covid-19, I can’t compare it against others but I already know. These are the fastest, and smoothest cutting blades I have ever used.

Ford Gerhold (verified owner) –

This metal cutting blade worked very well when I cut a steel electrical strut with it in my shop. I also tested it on a solid dry 2 by 4 stud in my shop and it worked well for that. I tried cutting a old outdoor 4 by 4 wood fence post with this blade and it did not work very well for that, so don’t expect it to work well on all wood types. This is definitely a good metal cutting blade as advertised and it works great for that.

Felicity Ebert (verified owner) –

This is an impressive blade. It’s very stiff and 1/16″ thick. I tried it on 1/2″ rebar and it cut through it like butter in only 6 seconds, making a clean, smooth cut. Out of curiosity I tried it on the 3/16″ aluminum decking I was installing and it seems like it couldn’t get a bite and just skipped over the surface, so I’ll be using it on thick metals as recommended.

Ellie Pacocha (verified owner) –

Milwaukee is my go-to on hand tools and cordless tools as Milwaukee items are well made and quality. I occasionally need to cut metal with a reciprocating saw in areas and on material I cannot use or get a chop-saw or torch to. These Milwaukee sawzall blades are nitrous carbide designed for thick/hard metal such as cast iron and stainless steel. While I’ve only tested this on one piece of angle iron, the blade cut through with ease.

Emiliano Erdman (verified owner) –

These Milwaukee SAWZALL® TORCH™ with NITRUS CARBIDE™ Blades are New for March of 2020.These blades are designed for cutting Cast Iron, and other thick metals like Black Pipe, Angle Iron, and Rebar to name a few. They can take a beating without snapping or breaking like many of the foreign made blades. These blades are made right here in the USA in Milwaukee Tools Greenwood Mississippi plant (See Photo). They cut faster, and last longer than any blades I’ve ever used.The blade incorporates a universal 1/2 inch tang that will fit just about any reciprocal saw from the old saws that used set screws to hold the blade, to the newer quick release designs. I used this blade in my 25 year old Milwaukee Sawzall Reciprocating Saw without any problems.The tip of the blade is blunt, not pointed (See Photo). It will deflect off objects it hits, and not stab into them. It has 7 TPI (Tooth Per Inch) and is 9 inches in length, great for cutting out old cast iron sewer pipe.You need to have these blades available when you need them, so pick some up so you will have them in your tool box available right when you need them.Always wear a respirator mask when cutting cast iron. Cast iron dust is extremely dangerous when inhaled into your lungs.Once you use Milwaukee blades, you will wonder why you ever tried to save a few bucks on those cheaper blades.

Monty Walsh (verified owner) –

These are heavy duty blades that are much more steadier than most blades on the market. You can use this blade to cut a variety of materials such as stainless steel, rebar , and angle iron. The unique alloy allows the blades to last three times longer than traditional blades. I used this blade with my handheld Milwaukee Sawzall and it worked nicely. The great things about these blades are that they are made in the United States. Nice product for my daily use.

Werner Greenholt (verified owner) –

This blade cut through a seized bolt like butter. Worth every penny.

Alisa Ankunding (verified owner) –

After trying out milwaukee carbide blades 2 years ago for some metal cutting I have to say I was very impressed with the cutting speed and blade longevity over their standard blades and stocked up on my commonly used sizes. Now here comes the Nitrus. I gave it a try and all I can say is WOW! The speed of cut and blade strength are phenomenal. I use a dewalt 10 amp corded recip saw for my heavy duty cutting and put this new blade through the paces. I cut through an old scrap jack I had. It cut the 1.25″ thick piston (see pics) in 21 seconds. I then cut through the saddle section with some odd angled pieces (another pic) in 29 seconds. I then decided to see how it handled wood since most metal specific blades are horrible in wood. I cut up some old fencing I had lying around, and while not as fast as a wood blade, it still cut with ease. After cutting i there was no noticable damage or wear to the blade. I will definitely be using these blades from now on whenever I have a metal cutting project.