Milwaukee 12 in. 7 TPI TORCH Nitrus Carbide Teeth Metal Cutting SAWZALL Reciprocating Saw Blade

$27.99

Make your cutting work more easier by choosing this Milwaukee TORCH Nitrus Carbide Teeth Metal Cutting SAWZALL Reciprocating Saw Blade

In stock

Description

The Milwaukee 12 in. 7TPI The TORCH with NITRUS CARBIDE SAWZALL Blade for CAST IRON and other thick metals is the next generation of carbide teeth technology. This SAWZALL blade with NITRUS CARBIDE teeth cuts longer, cuts more and cuts faster than traditional carbide teeth products on the market. Milwaukee NITRUS CARBIDE technology eliminates the tradeoff between blade life and speed of cut compared to traditional carbide teeth blades. The blade delivers 3X the life of existing carbide reciprocating saw blades to continuously make the toughest cast iron removals on the job. The TORCH SAWZALL blade with NITRUS CARBIDE cuts the thickest metals like cast iron and soil pipe. The unique carbide blend outperforms standard carbide teeth blades in common thick metals.

- Carbide teeth for 50x life in thick metal

- Carbide teeth for longer life and greater versatility

- Cuts cast iron, stainless steel and high strength alloys

- Fast in cast iron

- Offered in 1-pack, 3-pack, 5-pack and select 25-pack

- Up to 70% larger gullets for easy chip ejection

Additional information

| Weight | 0.2 lbs |

|---|---|

| Dimensions | 0.48 × 2.00 × 14.70 in |

| Blade Length (in.) | 12 |

| Blade Width (in.) | 1/20" |

| Color Family | Red |

| Demolition | Yes |

| Material Cut | Metal |

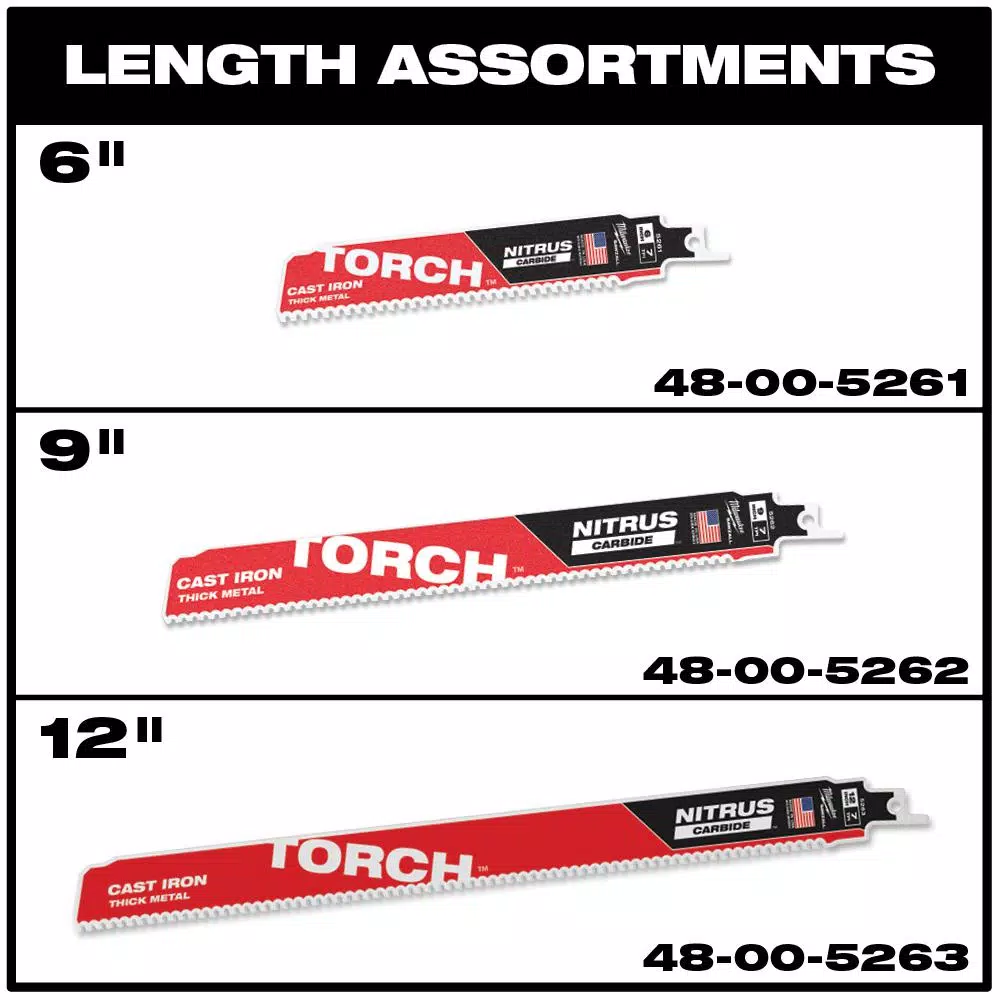

| Model | 48-00-5263 |

| Number in Package | 3 |

| Number of Teeth | 84 |

| Power Tool Accessory Type | Reciprocating Saw Blade |

| Saw Blade Material | Carbide |

| Teeth Per Inch | 7 |

| Tools Product Type | Power Tool |

Reviews (93)

93 reviews for Milwaukee 12 in. 7 TPI TORCH Nitrus Carbide Teeth Metal Cutting SAWZALL Reciprocating Saw Blade

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

Model# D1060XSaw Blades

Model# D0740RSaw Blades

Milwaukee 12 in. 5 Teeth per in. Wood Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5037Saw Blades

Milwaukee 12 in. 18 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5189Saw Blades

DEWALT Bi-Metal Reciprocating Saw Blade Set (15-Piece) with Tough Case

Model# DW4890Saw Blades

Model# D1080XSaw Blades

Model# 48-00-8788Saw Blades

DIABLO 10 in. x 80-Teeth Non-Ferrous / Plastic Cutting Saw Blade

Model# D1080N

Jacky Kozey (verified owner) –

Cuts hardened steel when normal metal blades don’t.The name “Torch” implies some serious cutting power. It makes me think of a cutting torch. Maybe not quite that good but they are still pretty good.I compared the cutting ability to a standard metal blade. On soft metals like a bolt, I really could not tell the difference.However, I tried cutting up an old hardened still wrench. The torch blade made it through in 38 seconds. My metal blade after 38 seconds barely scratched the wrench and the teeth were in pretty bad shape. The Torch teeth still looked pretty good after tearing through the hardened steel.I received these amazing MILWAUKEE 6 IN. 7 TPI TORCH NITRUS CARBIDE TEETH METAL CUTTING SAWZALL RECIPROCATING SAW BLADE (5-PACK) for free to write this review.

Oda Kunde (verified owner) –

I just want to say I absolutely love the Milwaukee Sawzall lineup including their blades. Their blades last the longest of any I’ve tried previously, and their line up of uses is A+. This Nitrus Carbide blade is handy for cutting any thicker metals, but specifically any old cast iron pipes. I don’t have cut a lot of thick metal, but I’m confident this thing will last a long, long time.

Shanie Stark (verified owner) –

I cannot say enough good things about this Milwaukee sawzall blade. The new carbide teeth really mean business! I use my sawzall for a lot of work around the house, yard and in the garage and this blade is a winner. I tested this blade on nails and some other smaller metal tasks and it performed well. Thick heavy steel is where this blade really shines, it’s cut like butter with hardly any force needed. Clean smooth cuts through a triple sleeved thick metal post that I had to cut up. After repeated cuts in thick metal it still seeems to have plenty of life left in it. This Milwaukee carbide will be my go to blade for thick metal. Highly recommend keeping one on hand.

Eliseo Nader (verified owner) –

Heavy Duty Sawzall Blades – at 7 Teeth per inch these are designed for thick metal.Blades are fully coated with what looks a epoxy or powder paint, this should prevent them from premature rust out.They are about 0.070 with a very narrow kerf, the blades are a solid piece. That is the teeth are not welded on.Work well on angle iron and black pipe, smooth cuts. They marked for cast iron, I have not needed to cut that yet.

Baylee Paucek (verified owner) –

Good blades

Rachelle Adams (verified owner) –

Good tough heavy-duty metal cutting blade. Used it on my cordless reciprocating saw to cut steel bar – sliced through like butter, with no sign of wear. It is a thick blade by most standards but works well to do the job. The total length is 9”, and the serrated (tooth) portion measures just a tad over 7” which is long enough to cut directly through both sides of the wall of a 4” diameter pipe. The blade thickness would seem to provide better stability for these longer cuts. The packaging suggests it will have a longer life expectancy than standard carbide blades, although I haven’t used this product long enough to judge that. It seems a tad pricey, but if remains durable (and sharp) through many cuts, it will be worth it. I would recommend this product.

Jamel Quigley (verified owner) –

Just a great reciprocating saw blade that can really handle what you throw it’s way. Very heavy duty and well made. Milwaukee has made another top notch sawzall blade that pairs well with any of their sawzall.I paired this blade with the M18 Fuel Brushless Sawzall and it had no problems handling what I threw its way. I only used it to cut some rebar but it cut threw it easily. You can see from the picture below that it holds up well under multiple uses. I cut some rebar 15 times and you can barely tell that the blade was used. I highly recommend this blade be added to your assortment of reciprocating saw blades.

Kelsi Lind (verified owner) –

The blade arrived quickly and was undamaged. It fit perfectly into my nonreciprocating saw even though it is not a Milwaukee brand tool. I was able to cut through metal easily with the blade. I have cut copper pipe as well as galvanized steel pipe with no problems. There appears to be no wear of the blade after the cutting I have done to date. Looks like it will have a good long life.

Bertrand Schinner (verified owner) –

This five-pack of 6 inch Milwaukee “Torch” reciprocating saw blades are exactly what you need to cut smaller diameter thick metal pipe. The blade has a one inch profile, carbide teeth (7 TPI – see picture), and that allows you to easily cut most any type of pipe under about 4 inches in diameter. Note that the actual cutting teeth are about 4.5 inches of the length of the blade (see picture). You insert the blade into the reciprocating saw after twisting open the ring that secures the blade (see picture), and you are ready to go! It is good to have a five-pack just in case you have a failure or want to switch to a new, cool blade if you heat up the one you are using (due to friction). I highly recommend this 6 inch blade five-pack!

Meredith Wehner (verified owner) –

Not all reciprocating saw blades are created equally, and this particular saw blade is no exception. Finding a blade that will cut thru a specific heavy metal like cast iron has been very difficult. Most bi-metal blades might make a slight cut but shortly after you get started, the teeth are worn down by metals like cast iron and rebar. This Milwaukee blade is the exception. It blasted thru the job of cutting up a small truckload of iron railings that had been taking up space in my back garden. It was a “shaky” task, because the reciprocating saw dis need to have some force applied to get started, but once the cut was started, it steadily cut thru the hard metal like a hot knife thru butter, but in slow motion. If you are looking for a hardworking saw blade to cut thru cast iron, this is the one. And it comes in a pack of 3 blades. I only used one and the teeth on that blade are barely worn down.. Highly recommended!

Filomena Kovacek (verified owner) –

To anybody who ever used a sawzall, the most important component is, without any doubts, the blade. Those are terrific and chop and cut any piece of sheet metal or copper pipe without much effort. Painfully noisy and messy process though, so stay safe with ear and eyes protections. Anyhow, those are great blades, you can’t go wrong with those. They don’t come cheap but really worth it.

Horace Ullrich (verified owner) –

These are some tough, tough blades. They are not for everyday cutting of thin or even medium steel. If you are cutting cast iron or structural steel with a reciprocating saw, these are the blades for you. The teeth are very broad so they will not work on thinner materials. I would not try on less than 1/8 or maybe even 3/16 steel. I used on some 3 1/2″ oil field pipe and the cut right through it. Not that it was fast but the blades made steady progress and did the job.

Colin Gorczany (verified owner) –

The heavy duty answer to cutting the harder metals or virtually anything that needs to be severed. Best use is for demolition or when rough cutting is adequate which is pretty much true for any application when using a reciprocating saw anyway. The price can be justified by their ruggedness to withstand the type of multiple cuts that would totally destroy ordinary blades.