Milwaukee 30 Deg. Knuckle Bit Holder Set (11-Piece)

$25.92

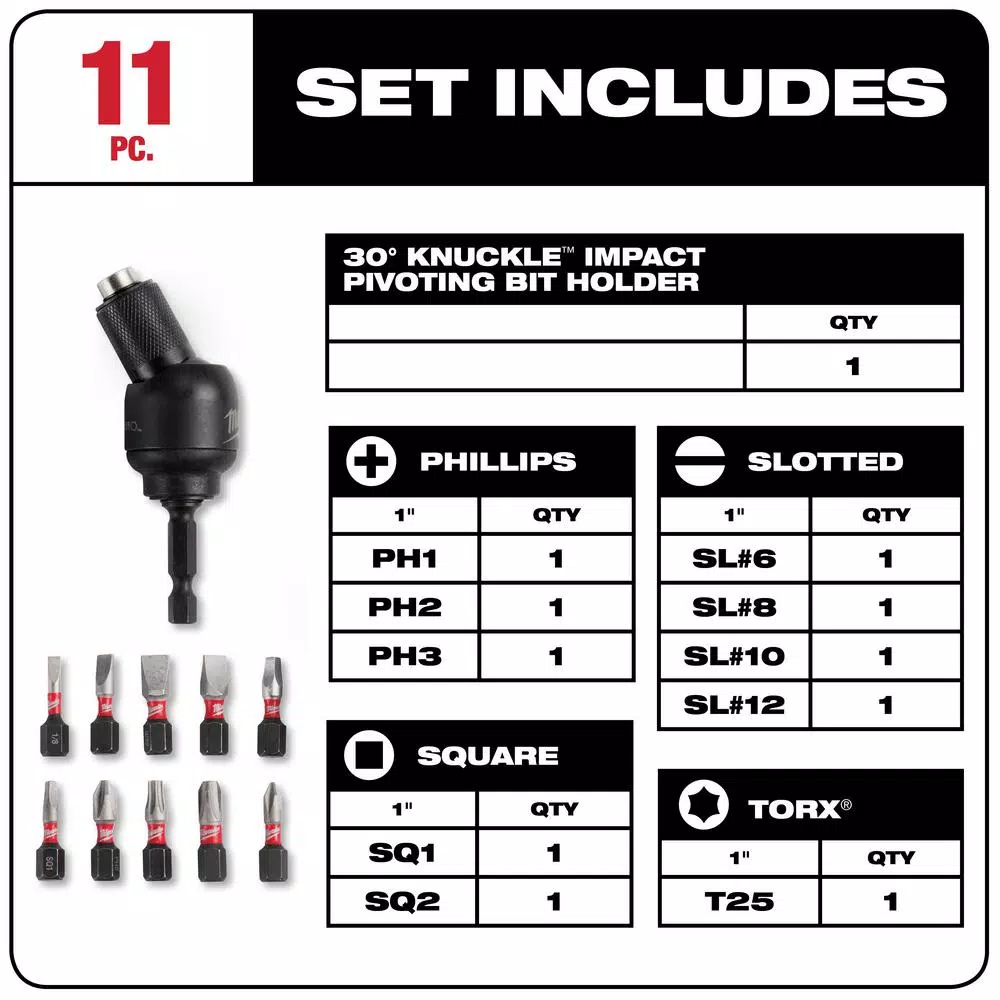

The MILWAUKEE® 11 Piece 30° SHOCKWAVE™ Knuckle™ Pivoting Bit Holder allows users to drive fasteners and drill holes in tight, difficult work areas. The innovative, compact design locks at a 0° or 30° angle and is designed for use with Milwaukee SHOCKWAVE™ Impact Duty™ ¼” hex accessories. Milwaukee 30 degree knuckle set is rated to handle up to 2,000 in/lbs of torque in impact drivers. The 30° Knuckle™ is engineered with SHOCKWAVE™ Impact Duty™ technology which is built for extreme durability and up to 30X life. The Milwaukee magnetic bit holder is made from proprietary steel, heat treated to control hardness. The SHOCKWAVE™ Impact Duty™ insert bits feature an innovatively designed geometric shock absorption zone to extend life. This bit set includes, Philips bits: 1” (1) P1, (1) P2, (1) P3, square bits: 1” (1) SQ1, (1) SQ2, slotted bits: 1” (1) SL ⅛”, (1) SL 3/16”, (1) SL1/4”, (1) SL 9/32”, Torx bits: 1” (1) T25.

In stock

Alice Lesch (verified owner) –

A stout pivoting angle drive that I will not hesitate to put to heavy use. This driver – and its complement of bits – are made of substantial materials that resist all the torque I can put through them. The device, itself, is rated over 166 FT-LBS. That’s more torque than one can apply to common fasteners before cam-out for most of the bits, even with significant down pressure applied! It is appreciably more than the setting torque for fasteners such as 7/8 dia. Grade 2 (fine), 5/8 dia. Grade 5 (fine), 5/8 dia Grade 8 (coarse) or 3/4 dia 18-8 (coarse). So it appears useful for driving some heavy duty recessed hex cap screws, etc. I don’t think I’m likely to encounter such uses, but realizing this capability gives me a lot of confidence in the tool; even with the added stresses of impact. As a result, higher classes of fastener fit pose no challenge. I also will not hesitate to chuck this up for loosening fasteners at awkward angles. I like the stiffness of the joint – it won’t slop about when setting up or in use. Your selection of 0 or 30 degrees stays set until the job is done. What I did have consternation about was that I inserted my first bit before examining the tool; then panicked when I couldn’t extract it – even after donning rubber gloves. Noting there are no product instructions, I reasoned it really can’t be that difficult. So I went to the Milwaukee Tool site only to find that some owners had given up on changing bits and declared their tools defective. However one persistent reviewer gave some advice I followed and retrieved my bit. THEN I looked into the socket and found a complete circumferential retainer spring bearing on all facets of the bit. I almost wished the retainer wasn’t so good. But a better thought; it will last a long time before fatiguing. So my only con is, “Maybe the Milwaukee designers could specify retainer springs which are shorter, ovoid or with a slightly lesser spring constant but equally long fatigue life…”

Alene Stracke (verified owner) –

Can’t seem to get this bit out ! No instructions ! Please help

Fatima Runolfsdottir (verified owner) –

Bits need more chamfer or radius for spring retainer to release bit, now bits release normal.

Luigi Donnelly (verified owner) –

The Shockwave impact Duty 30 Deg. knuckle bit holder set is the perfect tool to drive screws in tight quarters. When placed at 30 deg. the knuckle will drive screws at a constant velocity without jumping around. In the past I have tried to use a ¼ inch socket swivel with adapters on each side of the swivel to drive screws (see picture). A swivel is designed to tighten a nut or bolt at a slow speed not like driving a screw.What is great with the Milwaukee Knuckle it can be shifted from a straight drive to a 30-deg. angle drive with a push of your thumb. So, if you have a mix of tight versus normal screw driving environment there is no need to remove the Knuckle out of the impact drive. The kit comes with 10 Shockwave driving bits, but in my kit the bits were loose and had no place to store them.This is a special tool for tight spaces but when you need it, it works great.

Johnnie Lynch (verified owner) –

It works okay , I was hoping it would have had stronger magnetic properties to hold the screws , but it doesn’t seem to be magnetic at all

Kaitlin Bartell (verified owner) –

The Milwaukee 30 degree knuckle bit holder comes in handy when a straight in driver will not work. Has a bit holder to keep all of the bits in one place and the driver is heavy duty. Driver has a positive lock to keep the bits in place.

Kaci Grant (verified owner) –

Very robust and easy to use.This accessory is so easy to use, they don’t even include any instructions. The knuckle allows up to a 30 degree angle to be introduced into your powertrain. One end accepts standard ¼” hexagonal bits and the other end goes into a ¼” hex driver. It also has the detent allowing it to be securely held in an impact driver.It also comes with a selection of impact duty bits. You get:4 Flat bits: 1/8” 3/16” 1/4” 9/32” (who still uses flat bits, especially with an impact driver?)3 Phillips drivers: P1, P2, P32 Square drivers: SQ1, SQ21 Torx driver: T25I would have found additional Torx sizes more useful than flat bits.Having such a strong and secure drive joint will undoubtedly pay for itself the first time you need to drive something in a confined space that does not let your drive tool get lined up.The knuckle is easily held in place with one’s fingers. Everything feels very solid and good quality.Made in China