Milwaukee 12 in. x 44-Tooth and 80-Tooth Circular Saw Blade (2-Pack)

$84.97

The Milwaukee 4 and Circular Saw Blade segments to provide smooth, consistent finish. It includes optimized hole pattern for fast dust removal. It incorporates the newest technology in concrete cutting.

Only 10 left in stock

Description

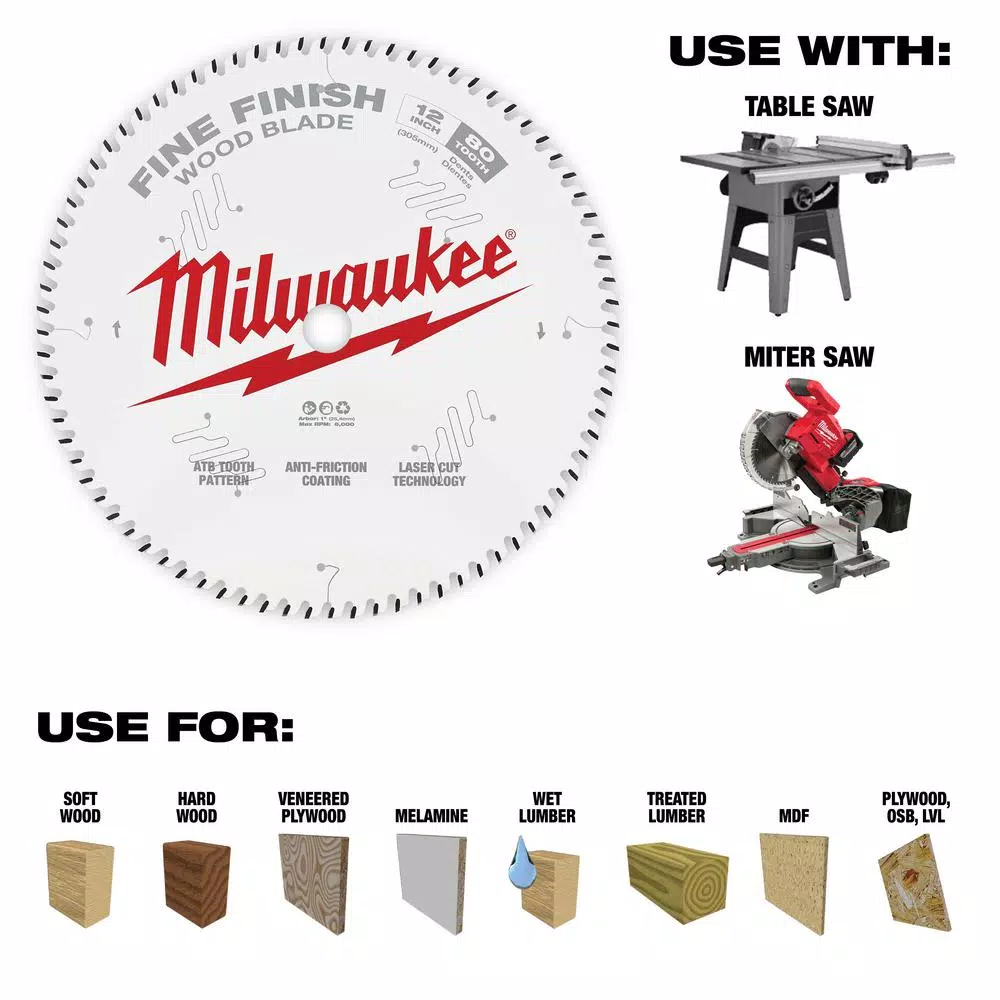

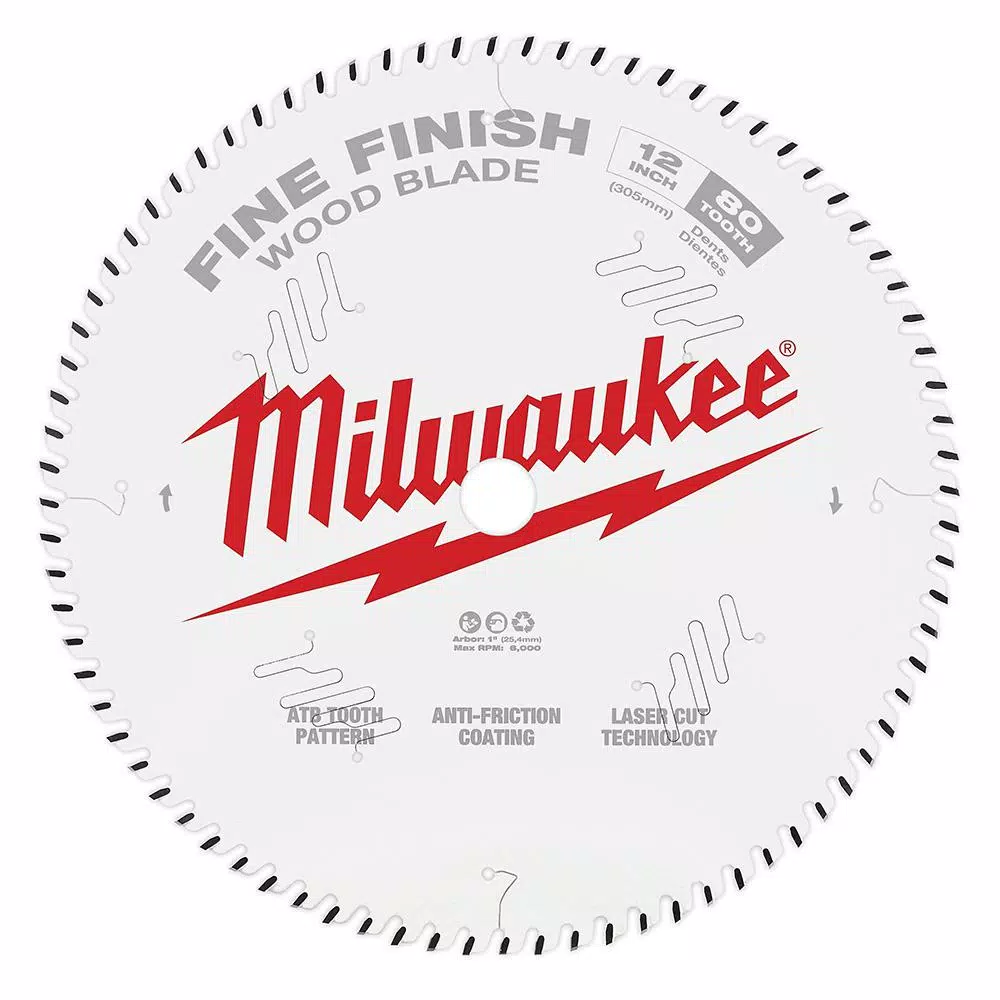

The 12 in. 2-pack item offers an 80-tooth fine finish blade as well as a 44-tooth general purpose blade. An anti-friction coating keeps the blade cool while cutting and resists corrosion and gumming. Laser cutting technology creates the blade from 100% sheet steel to ensure a stable blade that increases cutting accuracy. 12 in. blades are ring tensioned to further stabilize the blade. Laser cut vibration slots minimize wobble and warping during use. A thin kerf design delivers faster cuts as well as more cuts per charge when using a cordless tool. The 80-tooth fine finish blades ATB tooth pattern minimizes tearout in the cut material.

- Anti-friction coating

- Laser cut from sheet steel

- Polymer filled vibration slots

- Cobalt infused tungsten carbide

- Thin kerf blade

- Optimized for both cordless and corded tools

- Blade tensioning ring

- General purpose blade: 44-tooth; 1 in. arbor hole

- Fine finish blade: 80-tooth; 1 in. arbor hole

- Great for use with: softwoods, hardwoods, malamine, MDF, veneered plywoods, wet lumber, treated lumber and laminated woods such as plywood, OSB, LVL, PSL, LSL and OSL

Additional information

| Weight | 5.53 lbs |

|---|---|

| Dimensions | 0.39 × 13.78 × 16.71 in |

| Arbor Size | 1 |

| Color Family | Silver |

| Material Cut | Wood |

| Model | 48-40-1232 |

| Number in Package | 2 |

| Number of Teeth | 80 |

| Power Tool Accessory Type | Circular Saw Blade |

| Saw Blade Diameter (in) | 12 |

| Saw Blade Material | Carbide |

Reviews (23)

23 reviews for Milwaukee 12 in. x 44-Tooth and 80-Tooth Circular Saw Blade (2-Pack)

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

Milwaukee 8 in. 8/12 Teeth per in. Mutli-Material Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5093Saw Blades

Model# D1060XSaw Blades

Milwaukee 12 in. 5 Teeth per in. Wood Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5037Saw Blades

Milwaukee 6 in. 14 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5182Saw Blades

DEWALT 8 in. 18 Teeth per in. Demolition Reciprocating Saw Blade (5-Pack)

Model# DW4821Saw Blades

Milwaukee 6 in. 5 Teeth per in. Wood Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5035Saw Blades

Model# D1040XSaw Blades

Milwaukee 9 in. 18 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5188

Adolfo Wolf (verified owner) –

I have come to trust Milwaukee products and this blade is a prime example. Top quality and performance.

Leta Wiza (verified owner) –

I put this blade on my Dewalt 12″ sliding Miter saw. It has done a great job so far. I use it for trim as well as for general cuts. It is not a thin kerf blade and is a bit wider cut than my old blade was. So far cutting trim it has done real well making clean cuts. If I was just doing trim work I probably would buy a different blade, but for an all around good blade this one has done me well. I’ve been using it now for about 3 months.

Guadalupe Huels (verified owner) –

This is a really nice-looking saw blade. It is super sharp with tungsten carbide teeth. It also has laser cut slots to reduce saw wobble. I don’t know how that works but it looks really cool. It also has an anti-friction coating which stops it sticking. Milwaukee Tools makes good tools. Too bad they aren’t made in Milwaukee anymore, but instead are made in China.

Virginia D’Amore (verified owner) –

After I installed the saw on my table saw I checked it with my dial indictor. It was only .001 off which is the best I have ever had. So I started ripping some wood. I got a nice smooth cut with no tear out. I cut Walnut, White Oak and Pine. I am very pleased with the results I got from this blade. This is why I’m a Milwaukee fan for life. I have never been disappointed with a Milwaukee tool.

Schuyler Ferry (verified owner) –

Well balanced and very sharp, this saw blade cuts clean with little to no rough edge left behind.Both my chop saw and table saw use 10″ blades and I tried this one out on both.The table saw rip cut was smooth and easy cutting a 1-by into several strips. The cut edges were smooth with no tear out at the end.The chop saw was equally impressive. Nice, clean cuts with very fine saw dust and no splintered ends.

Reyna Christiansen (verified owner) –

Typical Milwaukee quality. Very cool cutting blades. Designed with ATB tooth pattern, Anti-friction coating, Tungsten Carbide infused with Cobalt teeth for super hardness and durability. Tungsten Carbide and Cobalt are used in machine shops to cut tough tool steel. They claim these blades are optimized for cordless and corded performance and that is one of the reason I decided to try these blades. I have a FlexVolt miter saw that I mostly use with the batteries. These blades cut smooth with little friction so I get more life out of a charge. The one negative I have is coating runs on the 44 tooth blade. I tend to question the quality control when I see something so obvious. There were 5 runs that were visible even before taking blades out of protective package. See photo. A HINT: the protective package is hinged on the bottom so carefully open the plastic welds along the top and sides and re-use the package to ensure longer life when storing blades. Cut up a storm safely my friend!

Bruce Steuber (verified owner) –

I got these to go on a sliding compound miter saw. I believe they are pretty universal as long as you need a 12″ blade. Since there are both a 44-tooth and an 80-tooth in the package, you are set to cut assorted materials. They seem to be straight and functional without any warping that I can see. They do not come in any kind of protective case but they hang on the wall on a nail just fine.

Luis Mraz (verified owner) –

Replaced original DeWalt blade with this one. Cuts much better and cleaner.

Macy Strosin (verified owner) –

Wow, I’m impressed. Smooth cuts fast. I highly recommend it.

Blaze Bradtke (verified owner) –

This is good, clean cutting saw blade. Surprisingly nice blade for the money that cuts a super clean miter. Didn’t think I would but actually love the white color, it reflects a lot of light down onto the wood making it easy to see your pencil cutting line. Longevity is yet to be determined. Cross cuts hard and soft woods with ease. Overall a great blade for the price, I will buy more.

Betty Langworth (verified owner) –

I use it everyday and holds up great!

Edyth Mills (verified owner) –

After installing the blade I checked for blade run-out (wobble) which was a very minor 0.003 inch or 0.076 mm. Yet when I measured the kerf I got in the oak it was 0.118 or 3 mm indicating the in use wobble was more like 0.006 still not a significant factor. The 0.118 kerf could be a binding problem if you have a riving knife or splitter greater in thickness than 0.116 on your saw. The carbide tips are very sharp but quite small though at this price point I don’t think resharpning is an option.I’m using a 1.75 hp. Hybrid cabinet saw with a zero clearance throat plate. The feed rate used was steady but not fast. I ripped 1 ½ inch thick kiln-dried oak and some pine 2×4’s. I also ripped 3 ½ inch oak and pine, basically resawing. Then just for “why not” I made a number of cross cuts using the same and to my surprise they came out quite nicely. Results are very satisfactory. This is definitely a great addition to my blade options. I am considering purchasing a Milwaukee 40 or 50 tooth combination blade in the future.

Marlin Howell (verified owner) –

Great price when on sale and I like to kee things Milwaukee with all my Milwaukee tools. I have had no issues this blade for all my framing needs

Keeley Orn (verified owner) –

This was a perfect fit for my table saw. The 50 tooth blade cuts very smooth even when doing 45 degree angle cuts. No binding. It allows you to rip thru long boards without waiting for the saw motor to keep up. Even works great when using pressure treated lumber. I am half way thru building a 8ft by 16ft deck and the blade is still cutting like new.

Aaron Schowalter (verified owner) –

These are outstanding replacement blades for my DeWALT 790 DHS Sliding Compound Miter Saw. The Milwaukee 12 in. 2-pack offers an 80-tooth fine finish blade as well as a 44-tooth general purpose blade. Both blades come with carbide teeth, have anti-friction coating that keeps the blades cool while cutting and that resists corrosion and gumming. Both blades are ring tensioned which stabilize the blade and minimize wobble and warping during use. A thin kerf design delivers faster cuts as well as more cuts per charge when using a cordless tool. The 80-tooth fine finish blades minimizes tear out in the cut material.

Elmer Runolfsson (verified owner) –

Milwaukee’s wood cutting, 10 in – 40 Tooth Blade is a general purpose blade is used for soft wood, hard wood, wet lumber, treated lumber, plywood, OSB and LVY. It can be used for a table saw or a miter saw. The blade has a cobalt infused tungsten carbide it will give a longer life than the standard type of blades. The anti-friction coating helps keeps the blade cool while cutting and resists corrosion and gumming. It has laser cut vibration slots that helps reduces wobble and warping when working. I used it cut some 2×4 and it cut it with ease. It left the end smooth. It is a great blade all purpose blade

Melisa Friesen (verified owner) –

This is the Milwaukee 48-40-1026, 10” by 50-tooth, combination, thin kerf (3/32”) saw blade (note that the package nowhere states the kerf—I measured it). The Home Depot website does state “Thin kerf blade.”. It has an anti-friction coating and the vibration slots are filled with a polymer, supposedly to reduce vibrations more so than just using the slots. The tooth pattern is ATB (alternate-tooth bevel). Milwaukee claims that the blade can be used with softwoods, hardwoods, melamine, wet lumber, treated lumber and laminated woods such as plywood, OSB, LVL, PSL, LSL and OSL.It’s worth noting that the blade comes in an easy-open package. In Photo 1 you can see the perforations (in the plastic and cardboard) allowing you to open the package from the back quite easily. Before installing the blade on my table saw, I checked it for flatness. Out of the package it was perfectly flat all across the blade. After installing the blade in my table saw, I tried both rip and cross cuts with a variety of woods. I noticed a bit of chatter with the blade as I cut 2” oak, which is not uncommon for thin kerf blades.Photos 2 and 3 show the bottom of the rip and cross cuts in white oak (the tops on all cuts, where the blade enters the wood, were uniformly good, so I’m not showing those photos). Photos 4 and 5 show the bottom rip and cross cuts in hard maple. I thought the rip cuts were excellent on these and other woods I tried. However, the crosscuts did show some tear out. The blade easily sliced through whatever I tried cutting, so it was good and sharp out of the package. Overall, given the price-point of the blade, I think it did a very good job.

Providenci Cummings (verified owner) –

Nice smooth cut

Dominic Skiles (verified owner) –

Replaced original DeWalt blade with this one. Cuts much better and cleaner.

Moshe Schultz (verified owner) –

I installed this Milwaukee 10″ General Purpose Blade on our Delta 5 HP Unisaw. I then helped a friend cut some scrap plywood so that he could make some speaker boxes. The blade seems to cut very easily and leaves a nice smooth edge with little to no tear-out on the bottom edge of the cut. Even thought the material we were cutting was not furniture grade, the cuts came out great. Very impressed!