Milwaukee 6-1/2 in. x 54 Carbide Teeth Aluminum Cutting Circular Saw Blade

$59.97

Instantly complete your drilling job in wood, plastic or metal surfaces with this amazing Milwaukee Teeth Aluminum Cutting Circular Saw Blade.

In stock

Description

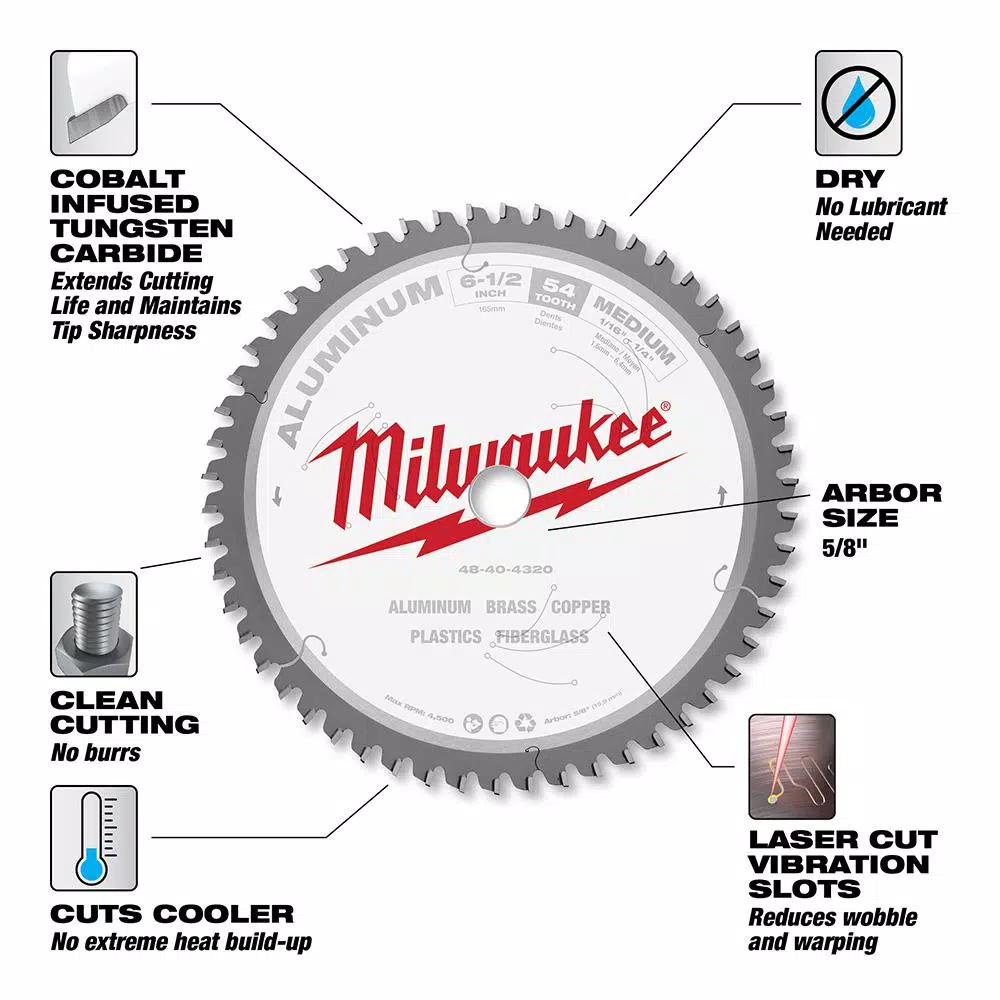

The Milwaukee 6-1/2 in. 54T Aluminum Cutting Metal Circular Saw Blades are specifically designed to exceed contractor’s expectations for blade life, cut quality and speed in the most demanding metal cutting applications – without a lubricant. The metal cutting circular saw blades have hand-tensioned hardened alloy steel bodies. This extends blade life and delivers the highest quality cuts available. The blades have Carbide-Tipped Teeth with Alternate Top Bevel grind to shear through metal delivering burr-free, cool-to-touch cuts.

- Engineered with cobalt infused tungsten carbide to extend cutting life

- Laser cut vibration dampening slots to minimize heat, sound and noise

- Ideal for dry metal cutting

- Cuts cooler for immediate handling and less down time

- Designed to provide clean cutting and a burr-free finish

Additional information

| Weight | 0.56 lbs |

|---|---|

| Dimensions | 0.28 × 8.27 × 9.65 in |

| Arbor Size | 58in |

| Color Family | White |

| Material Cut | Metal |

| Model | 48-40-4320 |

| Number in Package | 1 |

| Number of Teeth | 54 |

| Power Tool Accessory Type | Circular Saw Blade |

| Saw Blade Diameter (in) | 6-1/2 |

| Saw Blade Material | Carbide |

| Tools Product Type | Power Tool |

Reviews (60)

60 reviews for Milwaukee 6-1/2 in. x 54 Carbide Teeth Aluminum Cutting Circular Saw Blade

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

DIABLO 7-1/4 in. x 24-Teeth Tracking Point Framing Saw Blade

Model# D0724RSaw Blades

Milwaukee 44-7/8 in. 10/14 TPI Bi-Metal Deep Cut Portable Band Saw Blade

Model# 48-39-0550Saw Blades

Model# D1244XSaw Blades

Milwaukee 8 in. 8/12 Teeth per in. Mutli-Material Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5093Saw Blades

Model# D1040XSaw Blades

Model# 48-00-8788Saw Blades

Milwaukee 6 in. 5 Teeth per in. Wood Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5035Saw Blades

DEWALT Bi-Metal Reciprocating Saw Blade Set (15-Piece) with Tough Case

Model# DW4890

Alvah Kiehn (verified owner) –

Robust 80 Tooth, 12-inch metal and plastic cutting blade with a 5000 RPM limit (that’s high enough to use with a conventional wood working chop saw or miter saw). I used it in my 12-inch sliding compound miter saw to cut some 1/8″ aluminum bar stock and it did great. Very smooth cuts.1-inch arbor fit my saw perfectly. The package says it is recommended for thin metal (up to 3/32″) and medium metal (1/8″ to 1/4″) but NOT for thick metal (over 1/4″).It is NOT recommended for stainless steel, but the package says nothing about plain steel. Since it spins so fast, my feeling is it should not be used for plain steel either. Wish they would list that specifically on the package to avoid any confusion.It is recommended for Aluminum, Copper, Brass, Plastic and Fiberglass.Max RPM is 5000Arbor is 1″ (25.4 mm)

Karlee Prohaska (verified owner) –

Milwaukee 48-40-4370 14” 80 Tooth Carbide Circular Saw Blade – This Circular Saw Blade has Cobalt infused Tungsten Carbide, the blade is designed to be operated at 1800 RPM and installed on the Corded Metal Cutting Miter Saw…This blade is rated to cut medium thickness 1/16” to ¼” Aluminum, Brass, Copper, Fiberglass and Plastic, it will also cut thin up 3/32” Steel and medium 1/8” to ¼” steel…The blade has been designed to cut dry (no lubricant required) as well as cut cooler…I installed this blade on Milwaukee # 6190-20 Dry Cut Machine, this blade runs and cuts with less vibration due to (4) groups of equally spaced laser cut slots…I cut ¾” Grade “L” Copper Pipe, ¾” EMT, Aluminum Rain Gutter, 4” PVC Conduit and 7/8” Galvanized Super Channel…The blade performed as indicated, intended and expected without any problems…According to Milwaukee this blade is not rated to cut any metal thicker than ¼”…Milwaukee does manufacture (2) blades to cut metal up to ½”, a 72 tooth blade # 48-40-4505 and a 90 tooth blade # 48-40-4510, both blades are designed to be operated dry on a corded metal cutting miter saw…These blades produce burr free cuts on threaded rod or bolts…

Ahmed Casper (verified owner) –

I installed this blade in my Milwaukee battery miter saw. As expected, the 5/8” arbor size was correct for my saw but there is no other option. I tested the 48-40-4360 10” blade and the chart on the back of the package lists the recommended and acceptable uses, plus unacceptable materials. This blade is only recommended for thin metal up to 3/32” and medium metal (1/8”-1/4”), aluminum, copper/brass, and plastic/fiberglass. Not recommended for thick steel (1/4”-1/2”) or stainless steel. There is no recommendation for wood, but it cut select pine cleanly. I tried cutting thin steel channel and the blade cut cleanly through. I also tried PVC pipe with similar results. I did not have the other materials to test. When cutting the thin metal there were some sparks thrown off so it would be best to stay clear of flammables while cutting metal. The 70 tooth blade tips are cobalt infused tungsten carbide for long life. Laser cut groves in the body of the blade help prevent blade warping during repeated use. The blade mounted with the printing on the opposite side of my original blade. Be sure to check the proper rotation with the blade arrow when mounting the blade. The back indicates the blade should be used with cordless miter saws.

Jermaine Donnelly (verified owner) –

I can use this 9″ blade on my table saw with no problems. It cuts thru the aluminum all day and never seems to get dull. It doesn’t get clogged up with the shavings and runs cool and clean. I like how it cuts a clean edge with little or no effort. On the job site I dont have to keep changing the blade to cut the different metals that we are using. The blade doesn’t burn up like some cheap blades and it lasts all day. This is a great blade and has multiple uses on the site, Good choice.

Sabrina Corkery (verified owner) –

The blade is definitely sharp. The first cut was my finger nail as I tried to install the to my cordless circular hand saw. I was able to test it out by cutting a fiberglass to size. The cut was clean thanks to the 50 teeth. There was not too much vibration as I was cutting the fiber glass. I plan on cutting some copper using the blade and I am confident that I will also have a nice clean edge. The blade is strong and should last a myriad projects.

Maxine Schaden (verified owner) –

I used to cut aluminum square bar stock. Worked very well. Fast, burr free, very clean cuts.

Horacio Aufderhar (verified owner) –

I needed to cut some aluminum shower door hardware as part of a bathroom upgrade. Due to the size of the pieces and type of cuts to be made, I used this blade in my 10-inch table saw. This blade is for a saw with a one-inch arbor – but since my saw has a 5/8-inch arbor I had to use a brass adaptor.This blade seems to be top quality. The carbide-tipped teeth have an alternate top bevel grind, and there are numerous laser cut vibration dampening slots to minimize heat buildup and noise. It is designed to cut without any water or oil lubrication, which eliminates the hassle and mess.This blade worked flawlessly on the parts I cut and produced a fairly smooth finish. I am very satisfied with the quality and performance of this blade.

Keagan Doyle (verified owner) –

Excellent blade for cutting brass/light metals. This blade ripped through brass pipe with ease and without sharp edges – barely had to sand it down. Zero vibration while cutting! No heat or hot shards flying out – keeps it “cool” when cutting. 54 teeth provide this blade with smooth cutting and very few shards flying. Not recommended for 18-20v power tools, but with corded saw – this blade is a dream to cut light metal. It’s made in China, but with professional grade and according to Milwaukee standards. High level of confidence that this product will last. This blade is intended for light metals AND plastic/fiberglass. A perfect tungsten/carbide blade for one’s tool box! RECOMMEND!!! A+

Melvin Kuhic (verified owner) –

Milwaukee 8 in. x 60 Carbide Teeth Metal Cutting Circular Saw Blade is designed to cut non-ferrous metals (aluminum, brass, copper, etc.), plastic, fiberglass and thin metal up to 3/32-inch. It has cobalt infused tungsten carbide tipped teeth that runs cooler. It is substantially for softer materials without high iron (ferrite) content. Other more common blades are for ferrous metals. This blade has more teeth than the ferrous metal cutting blades and gives a cleaner cut in softer materials. With ferrous blades, feeding the material too fast can jam it and damage a tooth or send plenty of metal shavings flying. With plastic and fiberglass material this isn’t the same problem, the more teeth will result in a cleaner cut. It states on the package it is clog free, and has thin slots you can see in the photo’s to dampen vibration. I tried this blade out and had no problem, still very new. Milwaukee makes good saw blades so this should last when used with care and avoid the harder materials.

Colby Ledner (verified owner) –

The Milwaukee ten inch eighty tooth aluminum cutting saw blade is specifically designed to cut nonferrous metals, cuts are high quality and speed right through the most demanding metal cutting applications ;no lubrication is needed as this blade is designed for cool running. The metal cutting circular saw blades have hardened alloy steel bodies, thus extending blade life and delivering high quality cuts. The teeth are carbide tipped and have alternating bevel grind to shear through metal delivering burr free, cool to touch cuts.This uses tungsten carbide to extend cutting life and has laser cut vibration dampening slots to minimize heat, sound and noise. Clean, cool and burr free cuts are the claim to fame of this blade.

Clemmie Dickinson (verified owner) –

This Milwaukee Metal Cutting Saw blade actually needed to list Non-Ferrous Blade in its listing. As for its cutting ability it is actually very good for aluminum, copper, brass, fiberglass and most plastics. For a 14-inch blade with a 1-inch arbor it will fit a chop miter saw or a powered cut-off saw. The cut-off saws now come in gas or battery powered units. If you are working in an aluminum fabrication shop this would be a must have because the cuts are that clean, needing no additional preparation to go to the TIG welder. The other materials are generally cut by miter saws only in pre-fab home construction on a demanding basis that would call for this blade. In my case using a blade like this with such a narrow material base does not compare. There are too many blades in this size range that will cut all of these materials PLUS ferrous metals (iron & steels), along with woods. The pictures below would have shown a complete comparison of the blade cuts; however, my neighbor took his Aluminum and Copper blocks that were cut back before I hand a chance to get the picture, due to a call back to work. The cuts were however, extremely clean for both saw blades. This blade is an excellent choice for the fabrication professionals who do not use wood or ferrous metals. For that reason and those areas only would you find this blade an excellent choice.

Anna Crona (verified owner) –

I received the MILWAUKEE 9 IN. X 72 CARBIDE TEETH METAL CUTTING CIRCULAR SAW BLADE to test for The Home Depot. I used it with my sliding miter saw to cut standing seam roofing for my pergola and it worked great! Ran through the pieces like butter. What i really liked is the packaging. It is perforated for opening so that it can be used for storage as well. Simple but a great idea.

Krista Langworth (verified owner) –

If you need a quick method for cutting soft metal like copper, aluminum, medium metal 1/8 to 1/4 inch and plastic or fiberglass this is the blade. I would recommend wearing eye protection and even long sleeve shirts and pants as the blade can throw small bits off when cutting the materials mentioned. I obtained to cut fiberglass roofing on a patio and am waiting on cooler weather to use. The blade cut thru the copper like it was butter so I know it will handle the fiberglass with ease.

Wade Kemmer (verified owner) –

I have cut some stuff that is way beyond what it supposed to be used for.

Burnice Daugherty (verified owner) –

Milwaukee 48-40-4370 14” 80 Tooth Carbide Circular Saw Blade – This Circular Saw Blade has Cobalt infused Tungsten Carbide, the blade is designed to be operated at 1800 RPM and installed on the Corded Metal Cutting Miter Saw…This blade is rated to cut medium thickness 1/16” to ¼” Aluminum, Brass, Copper, Fiberglass and Plastic, it will also cut thin up 3/32” Steel and medium 1/8” to ¼” steel…The blade has been designed to cut dry (no lubricant required) as well as cut cooler…I installed this blade on Milwaukee # 6190-20 Dry Cut Machine, this blade runs and cuts with less vibration due to (4) groups of equally spaced laser cut slots…I cut ¾” Grade “L” Copper Pipe, ¾” EMT, Aluminum Rain Gutter, 4” PVC Conduit and 7/8” Galvanized Super Channel…The blade performed as indicated, intended and expected without any problems…According to Milwaukee this blade is not rated to cut any metal thicker than ¼”…Milwaukee does manufacture (2) blades to cut metal up to ½”, a 72 tooth blade # 48-40-4505 and a 90 tooth blade # 48-40-4510, both blades are designed to be operated dry on a corded metal cutting miter saw…These blades produce burr free cuts on threaded rod or bolts…

Hank Weber (verified owner) –

The Milwaukee seven and a quarter inch (7 ¼”) by fifty-six (56) tooth carbide metal cutting circular saw blade is capable of cutting brass, aluminum, fiberglass, copper , vinyl, and any nonferrous metals up to a quarter inch (1/4”) (6.4 mm) thick. WEAR SAFETY GLASSES! as this does throw minute shavings. One note is that the cut material is not hot to the touch after cutting and no oil is required during cutting operation.

Jimmie Eichmann (verified owner) –

Once I finally “liberated” the MILWAUKEE CIRCULAR SAW BLADE from it excessive packaging, everything else was easy-peasy!The blade installed easily. Of course, I did install the blade backwards on my saw. Thank goodness for the arrows, huh?The blade cuts well. It replaces a Milwaukee 60-tooth blade, so I did notice cleaner cuts when I used it on wood and aluminum.

Jaleel Bernhard (verified owner) –

I received the Milwaukee 6-1/2 in. x 54 Carbide Teeth Metal Cutting Circular Saw Blade to review for free. This blade has carbide teeth and will work with a circular saw to cut specifically designed to cut nonferrous metals like aluminum, brass, copper, plastic and fiberglass. It’s designed to work without a lubricant and reduce heat. It’s also designed to cut burr free.

Belle Goldner (verified owner) –

I have been using this blades for the last 10 years and they work excellent.

Juvenal Raynor (verified owner) –

I tried this blade on an aluminum gutter downspout and on a piece of one inch thick plastic. It worked well on both applications. I had to use a hub spacer to compensate for the hole diameter of the blade. It was 1/8 inch larger than the hub on the saw I was using. Both cuts were quick and easy with good results. I did have burrs on the aluminum downspout but I used a soft wire wheel to clean up the cut. This blade definitely speeds up the cutting process when doing things like gutter installs or repairs. The plastic cut clean and smooth with minimal burr issues.