Milwaukee 7-1/4 in. x 56 Carbide Teeth Aluminum Cutting Circular Saw Blade

$54.97

Instantly complete your drilling job in wood, plastic or metal surfaces with this amazing Milwaukee Teeth Aluminum Cutting Circular Saw Blade.

In stock

Description

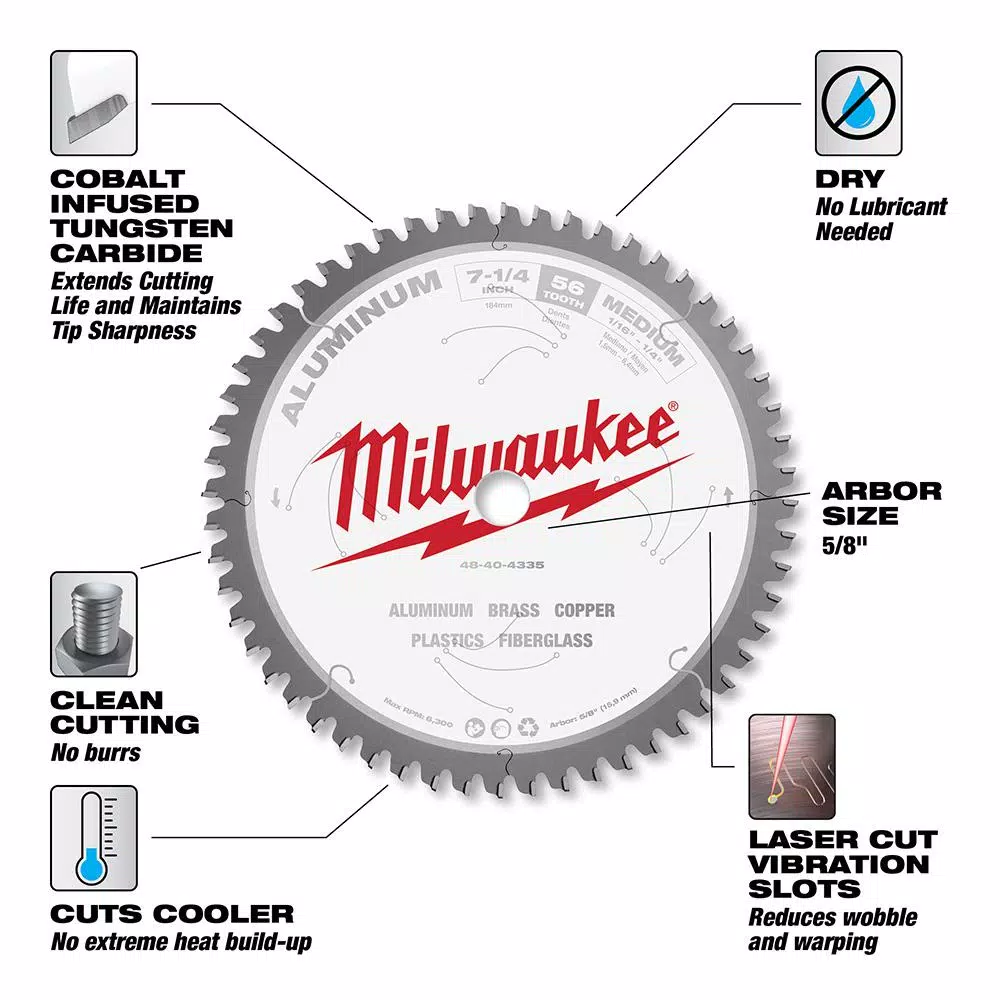

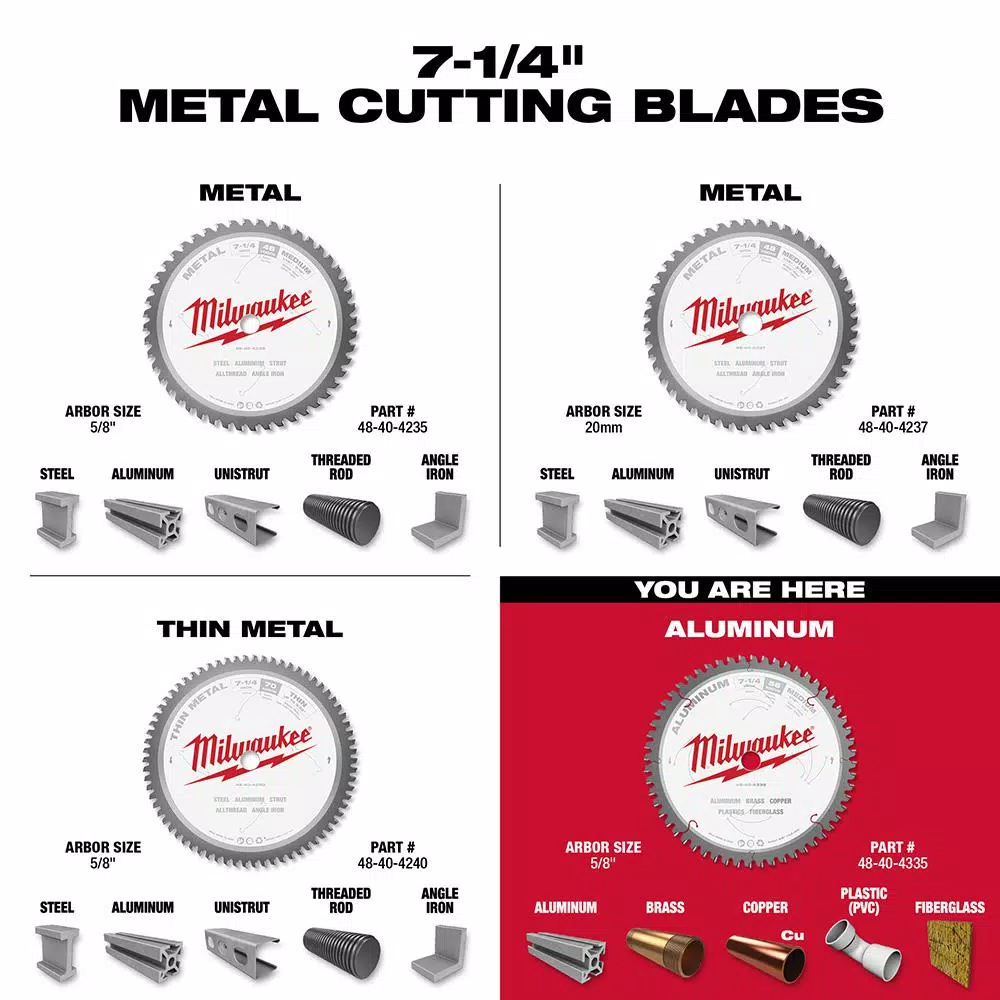

The Milwaukee 7-1/4 in. 56T Aluminum Cutting Metal Circular Saw Blades are specifically designed to exceed contractor’s expectations for blade life, cut quality and speed in the most demanding metal cutting applications – without a lubricant. The metal cutting circular saw blades have hand-tensioned hardened alloy steel bodies. This extends blade life and delivers the highest quality cuts available. The blades have Carbide-Tipped Teeth with Alternate Top Bevel grind to shear through metal delivering burr-free, cool-to-touch cuts.

- Engineered with cobalt infused tungsten carbide to extend cutting life

- Laser cut vibration dampening slots to minimize heat, sound and noise

- Ideal for dry metal cutting

- Cuts cooler for immediate handling and less down time

- Designed to provide clean cutting and a burr-free finish

Additional information

| Weight | 0.76 lbs |

|---|---|

| Dimensions | 0.28 × 9.06 × 10.63 in |

| Arbor Size | 58in |

| Color Family | White |

| Material Cut | Metal |

| Model | 48-40-4335 |

| Number in Package | 1 |

| Number of Teeth | 56 |

| Power Tool Accessory Type | Circular Saw Blade |

| Saw Blade Diameter (in) | 7-1/4 |

| Saw Blade Material | Carbide |

| Tools Product Type | Power Tool |

Reviews (60)

60 reviews for Milwaukee 7-1/4 in. x 56 Carbide Teeth Aluminum Cutting Circular Saw Blade

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

DEWALT 8 in. 18 Teeth per in. Demolition Reciprocating Saw Blade (5-Pack)

Model# DW4821Saw Blades

Milwaukee 12 in. 5 TPI Pruning SAWZALL Reciprocating Saw Blades (5-Pack)

Model# 48-00-1303Saw Blades

DIABLO 10 in. x 80-Teeth Non-Ferrous / Plastic Cutting Saw Blade

Model# D1080NSaw Blades

Milwaukee 12 in. 5 Teeth per in. Wood Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5037Saw Blades

Milwaukee 6 in. 14 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5182Saw Blades

Milwaukee 44-7/8 in. 10/14 TPI Bi-Metal Deep Cut Portable Band Saw Blade

Model# 48-39-0550Saw Blades

Milwaukee 6 in. 24 Teeth per in. Thin Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5186Saw Blades

Milwaukee 44-7/8 in. 18 TPI Bi-Metal Deep Cut Portable Band Saw Blade

Model# 48-39-0520

Juana Treutel (verified owner) –

This saw blade is excellent for cutting metal or plastic. Fine enough teeth to make a super smooth cut. No buts to clean on plastic pipe or aluminum. Put it in my Milwaukee circular saw and made several cuts to see how it worked. None better than this. I tried it on sheet metal and it worked great. I am going to use it to cut 8 foot sections down to 4 foot. So much better than turning a wood blade around backwards to cut sheet metal. I hih hoy recommend this excellent quality blade!

April Reinger (verified owner) –

I love these 8 inch blades. This 58 tooth gives you smooth, fast cuts in aluminum, plastics, fiberglass, copper and brass. It’s excellent for cutting sheets of aluminum or fiberglass, as it cuts cleanly and doesn’t heat up like some. With more plastics being used, this works great for making smooth accurate cutting there too. The teeth are ‘cobalt infused tungsten carbide’ and no lubrication is needed. It didn’t clog up with material like some I’ve used in the past. This is perfect for my 8 inch metal saw. If you have an 8 inch metal saw, why not use an 8 inch blade? If you haven’t tried these newest blades, give them a try. They perform flawlessly and save time too.

Osvaldo Cassin (verified owner) –

The Milwaukee 8″ metal cutting blade definitely will get the job done. I use this blade in a Milwaukee m18 cordless metal saw, and I’m impressed with how smooth the cut is. The blade definitely lasted a good amount of time as long as you dont force it through the cut. The last thing you want to do is to increase the heat the blade gets from cutting so let it do the work.

Fern Donnelly (verified owner) –

Worked like a knife through butter.

Jacky Murphy (verified owner) –

I had to install a Plexiglas shield at a service counter which required cutting aluminum trim and Plexiglas panels. I purchased a Milwaukee cordless metal cutting saw to go with this blade and it did the job. The blade works well with the Plexiglas with just a little gumming up from the heat and friction. It handled the aluminum trim pretty easily and was a lot easier cutting than with a hacksaw. This is a good quality blade.

Ross Abshire (verified owner) –

Nice blade and great smooth cut with no burning or fraying of any amount. Very impressed.

Vada Gleason (verified owner) –

i build powerlines and we use this for cutting 1 in. bolts on hiline job! best bade ever.

Cleora Hayes (verified owner) –

Great blades, too bad these aren’t available in store EVER!!!

Jarret Toy (verified owner) –

Milwaukee 48-40-4370 14” 80 Tooth Carbide Circular Saw Blade – This Circular Saw Blade has Cobalt infused Tungsten Carbide, the blade is designed to be operated at 1800 RPM and installed on the Corded Metal Cutting Miter Saw…This blade is rated to cut medium thickness 1/16” to ¼” Aluminum, Brass, Copper, Fiberglass and Plastic, it will also cut thin up 3/32” Steel and medium 1/8” to ¼” steel…The blade has been designed to cut dry (no lubricant required) as well as cut cooler…I installed this blade on Milwaukee # 6190-20 Dry Cut Machine, this blade runs and cuts with less vibration due to (4) groups of equally spaced laser cut slots…I cut ¾” Grade “L” Copper Pipe, ¾” EMT, Aluminum Rain Gutter, 4” PVC Conduit and 7/8” Galvanized Super Channel…The blade performed as indicated, intended and expected without any problems…According to Milwaukee this blade is not rated to cut any metal thicker than ¼”…Milwaukee does manufacture (2) blades to cut metal up to ½”, a 72 tooth blade # 48-40-4505 and a 90 tooth blade # 48-40-4510, both blades are designed to be operated dry on a corded metal cutting miter saw…These blades produce burr free cuts on threaded rod or bolts…

Rubye Boyle (verified owner) –

I installed this blade in my Milwaukee battery miter saw. As expected, the 5/8” arbor size was correct for my saw but there is no other option. I tested the 48-40-4360 10” blade and the chart on the back of the package lists the recommended and acceptable uses, plus unacceptable materials. This blade is only recommended for thin metal up to 3/32” and medium metal (1/8”-1/4”), aluminum, copper/brass, and plastic/fiberglass. Not recommended for thick steel (1/4”-1/2”) or stainless steel. There is no recommendation for wood, but it cut select pine cleanly. I tried cutting thin steel channel and the blade cut cleanly through. I also tried PVC pipe with similar results. I did not have the other materials to test. When cutting the thin metal there were some sparks thrown off so it would be best to stay clear of flammables while cutting metal. The 70 tooth blade tips are cobalt infused tungsten carbide for long life. Laser cut groves in the body of the blade help prevent blade warping during repeated use. The blade mounted with the printing on the opposite side of my original blade. Be sure to check the proper rotation with the blade arrow when mounting the blade. The back indicates the blade should be used with cordless miter saws.

Gennaro Bernhard (verified owner) –

This Milwaukee non-ferrous metal cutting circular saw blade cuts through items like butter! I actually used it to cut through 1-1/2″ PVC piping and it was so fast and easy to complete my project. The only thing I will say to be aware of is that it has a 20mm arbor which isn’t compatible with some of the circular saws out there. I have a Ryobi 18V circular saw and had to use an “adaptor” that was made by a friend and it worked fine but I would probably buy a blade that is actually made for my saw.This Milwaukee blade is high quality and cuts really well. I’ve used a lot of tool accessories by Milwaukee and have found them to last longer and perform better than other brands. This blade is made for aluminum, brass, copper, plastics and fiberglass. Just an FYI that the 5-7/8″ blade will not work on the Ryobi 5-1/2″ circular saw as it hits the safety shield. I had to install it on my 6-1/2″ circular saw so it would rotate properly without any safety worries. Remove the blade from it’s packaging by just cutting down about an inch from the top and sliding out the blade. You can then reuse the packaging to store the blade safely. I highly recommend this brand of blades.

Kenny Padberg (verified owner) –

This Milwaukee 5 7/8” diameter 50 tooth aluminum cutting blade powers through aluminum sheet and angle like cutting through wood. The resulting kerf is precise, clean and smooth. I do not own a hand held circular saw with a 20mm arbor so I made an adapter to use this blade. I used this in a corded 7” hand held circular saw to try it out and had great results. In the past I have used either a jigsaw or reciprocating saw to make these cuts and then had to clean them up by filing or grinding. Very difficult to get a long smooth straight cut that way. This is a very nice and welcome addition to my workshop. It would have been nice if the packaging could be more easily reused for storage between uses. It is very difficult to initially remove the blade from the package and getting the blade in and out through the opening made in the back of the package is difficult when using it for storage.

Dessie Ziemann (verified owner) –

I have been a builder and remodeler for 50 years, and as such I have had many occasions where I had to cut aluminum and plastics. But while I could use other blades like a wood blade or others, often it is better if I an just use the blades made to cut the material. For example, this MILWAUKEE 10 IN. X 80 CARBIDE TEETH METAL CUTTING CIRCULAR SAW BLADE. I recently used it to cut some aluminum and also some PVC trim, and it cuts cleaner and easier than a wood blade.

Henderson Walsh (verified owner) –

I received the MILWAUKEE 9 IN. X 72 CARBIDE TEETH METAL CUTTING CIRCULAR SAW BLADE to test for The Home Depot. I used it with my sliding miter saw to cut standing seam roofing for my pergola and it worked great! Ran through the pieces like butter. What i really liked is the packaging. It is perforated for opening so that it can be used for storage as well. Simple but a great idea.

Perry Beer (verified owner) –

The Milwaukee ten inch eighty tooth aluminum cutting saw blade is specifically designed to cut nonferrous metals, cuts are high quality and speed right through the most demanding metal cutting applications ;no lubrication is needed as this blade is designed for cool running. The metal cutting circular saw blades have hardened alloy steel bodies, thus extending blade life and delivering high quality cuts. The teeth are carbide tipped and have alternating bevel grind to shear through metal delivering burr free, cool to touch cuts. This uses tungsten carbide to extend cutting life and has laser cut vibration dampening slots to minimize heat, sound and noise. Clean, cool and burr free cuts are the claim to fame of this blade.

Rosalee Haley (verified owner) –

So far so good. I’m not used to using a carbide tooth blade to cut metals. Usually I use the old style abrasive blades or wheels. But I’m definitely liking the carbide tooth blade mush better. Milwaukee made some pretty good blades here. I used the blade to cut some copper pipe, aluminum sheeting and some fiberglass panels and all worked out great. For the copper it was really fast and the metal stayed cool. It didn’t heat up or spark like crazy. The aluminum sheeting cuts were perfect also. Actually surprised how there wasn’t many burrs if any at all when I had a good straight line going. I also cut some thin metals on some blinds to cut the track to size and it sure beat using a hacksaw. I really like how clean this blade cuts with no burrs or burn marks. Definitely wear eye protection because little flakes of metal can jump around depending on the saw. I used it on my Milwaukee 6 1/2 saw and the rpms suited it well. All the carbide teeth are still there after me using it and still sharp. Definitely looking forward to using this style blade now to cut metal. Hopefully Milwaukee makes some 1/8” thickness metal cutting blades in the future for some softer steel. Definitely good quality carbide material used in this blade.

Luz Braun (verified owner) –

I ordered this blade to cut a number of different materials including plastic pipe. In the past I’ve done it with just a regular carbide blade with good results. In this case, I needed to get a better cut for my current project, not actually plumbing but building a drone, so I ordered this 10 inch metal cutting blade to use on my compound miter saw. It really allows for a precise cut even on larger diameter pipe.One word of caution, using this blade on any material generates a large amount of very fine dust. I was shocked @ how much floats around during the cutting process; wear good safety glasses.

Angus Cremin (verified owner) –

“Metal” Cutting?For SOFT METALS, this blade works well. I tested it on an aluminum threshold. Not only did it cut cleanly, (see photo) but the aluminum was cool-to-the-touch afterwards.Later I tested it on PVC pipe and PVC stair balusters. It cut those soft materials easily, as you would expect. Although I recommend faster feed-speed for plastic materials because slow-feed can cause plastic to melt. This blade is thin. That’s why it can claim to be “optimized for cordless” saws. The idea is simple; A thin blade requires less force to cut stuff, and therefore, uses less battery power. However, cutting SOFT metals is not very demanding. It’s often LESS demanding than cutting wood. You’d have to cut a LOT of thick aluminum before depleting any decent battery. Therefore, the “optimized for cordless tools” meme is largely irrelevant. That brings me to the only criticisms I have, which are NOT about the blade itself, but the WAY it is described on the HD website and the blade. Instead of saying it is a “metal cutting blade,” the product description should say “for SOFT metals,” or say “for NON-FERROUS metals.” But it DOES NOT say that in the description. That only says, “Metal Cutting Circular Saw Blade.”To be fair, if you look VERY closely on a LARGE monitor, it says “Aluminum” right on the product photo, AND in some tiny side-bar photographs.But if you only read the product description you would NOT know this is ONLY for SOFT NON-FERROUS metals. And if you quickly viewed these product photos on a small phone, you could easily be led astray.I offer that information to help others avoid mistakes.Another point of contention is the advertising statement: “Optimized for cordless AND corded performance.”That makes NO sense. There ARE ONLY TWO types of power saws: 1-corded, and 2-cordless. It cannot be “optimized” for BOTH. That is as silly as saying, [This heater is] “…ideal for large AND small rooms.” Although a thin blade may require less power to use, it cannot make electric current from your outlets last longer. It can “be optimized” for one, or the other, but NOT both. That’s what “optimized” means!But to say it is “optimized” for BOTH types of tools is a confusing corruption of language and logic. Likewise, there is no need to say these are “professionally” made in China. The term “professional” means work is done to earn wages. ALL commercial products are made “professionally” in that sense. Adding that unnecessary term does NOT fool intelligent readers into believing these are inherently better than other blades that simply and honestly say, “Made in China.”It would serve Milwaukee well to hire advertising people who don’t confuse customers with silly illogical statements, or deceptive superfluous verbiage. After all, we KNOW that the appearance of a product package is important for favorable marketing images. So you KNOW that many people had to READ those words before the final design was approved. Yet apparently nobody noticed these glaring illogical statements. Hire anyone who reads English at a fourth-grade level to proofread your ad copy and product descriptions. Get someone to view these webpages on a modern mobile device so they can SEE what customers might see. Apart from the misleading product description, the light grey lettering on a white blade against a white background which is hard to see on a small screen, and that nonsensical advertising fluff, I can recommend this blade for SOFT NON-FERROUS metals like Aluminum, Copper and Brass. This blade could be used for PVC plastics in a pinch, but there are other blades specifically designed or “optimized” for those materials because they prevent melting. In fairness to Home Depot and other Chinese blades, you should search the normally excellent Home Depot website for “aluminum cutting circular saw blade.” There you will find other SOFT METAL cutting blades that are not only labeled correctly, but cost much less.

Kristopher Murray (verified owner) –

The blade is definitely sharp. The first cut was my finger nail as I tried to install the to my cordless circular hand saw. I was able to test it out by cutting a fiberglass to size. The cut was clean thanks to the 50 teeth. There was not too much vibration as I was cutting the fiber glass. I plan on cutting some copper using the blade and I am confident that I will also have a nice clean edge. The blade is strong and should last a myriad projects.

Vanessa Ernser (verified owner) –

I ordered this blade to cut down some old metal picture frames myself instead of taking them to a picture frame shop & spending almost as much money as the price of this blade. Seems that I can now do this myself with near professional results. More than likely I’m the only one that could tell it wasn’t done professionally. One word of caution, using this blade on any material generates a large amount of very fine dust. I was shocked @ how much floats around during the cutting process; wear good safety glasses.