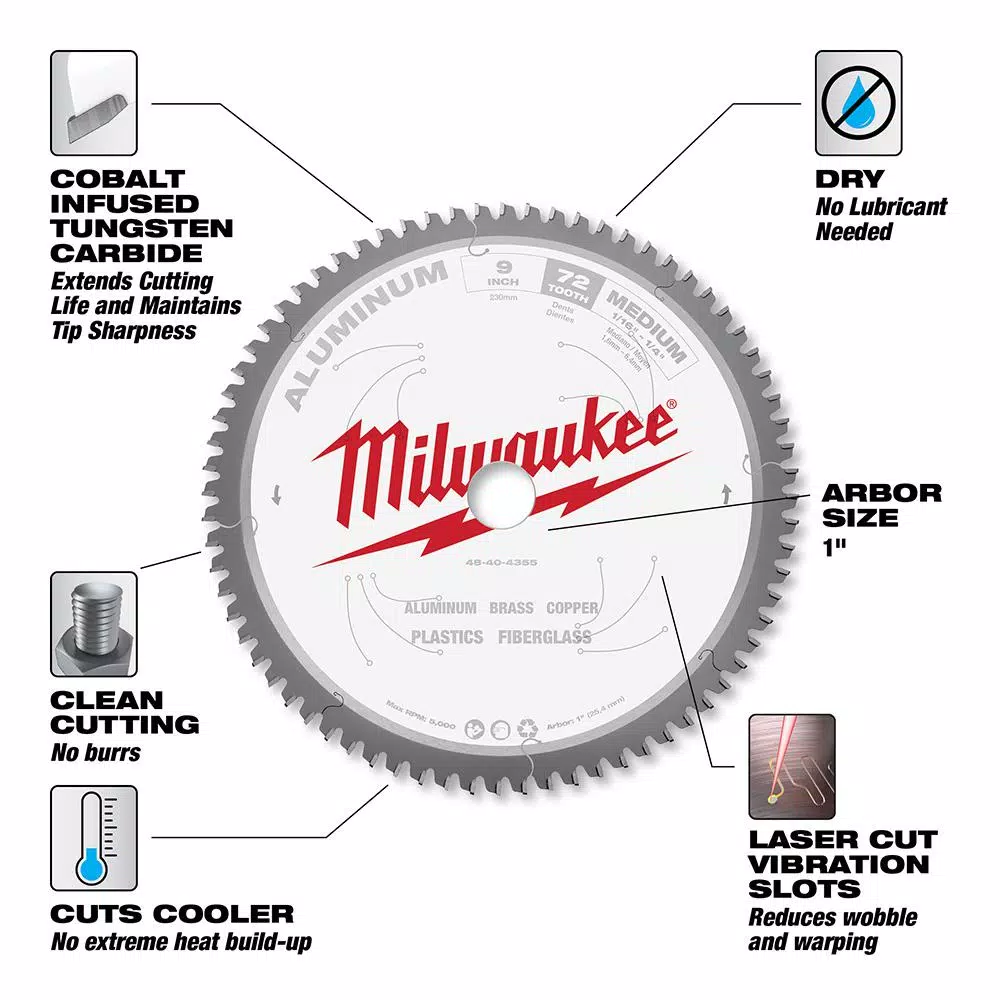

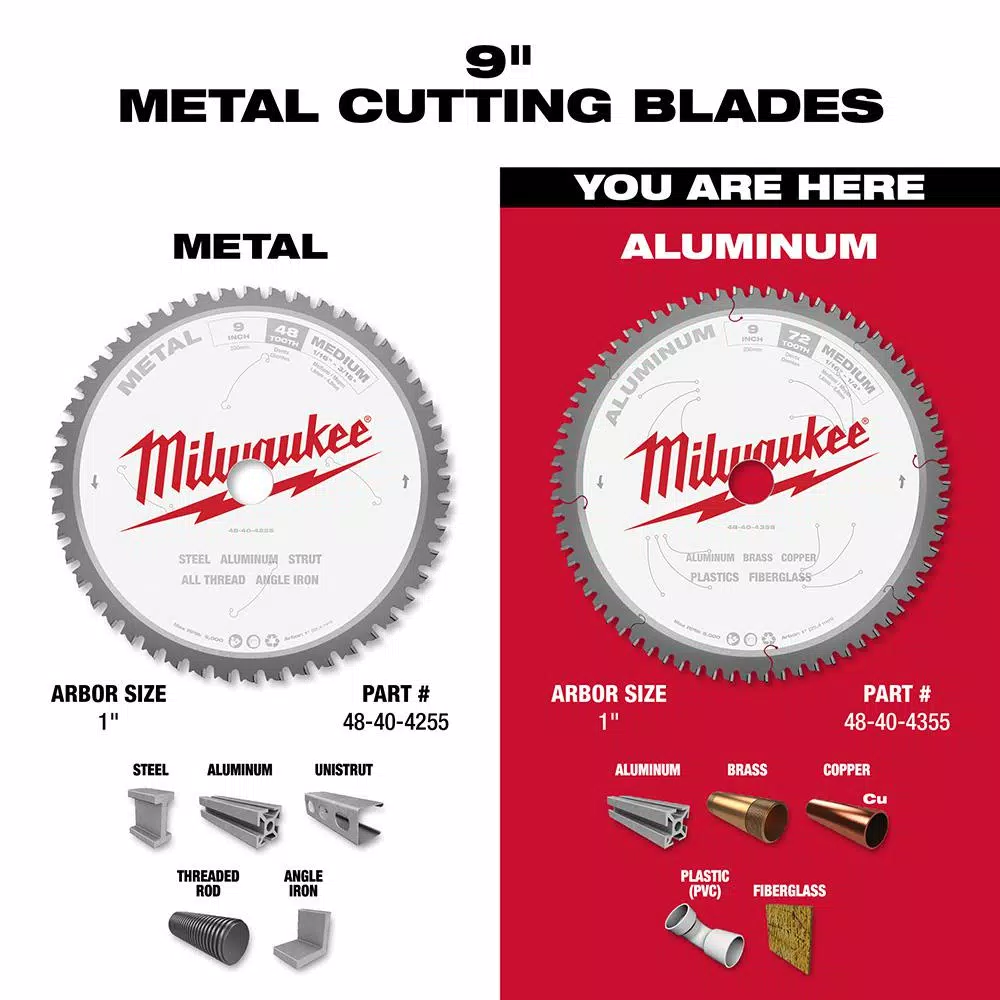

Milwaukee 9 in. x 72 Carbide Teeth Aluminum Cutting Circular Saw Blade

$99.97

Instantly complete your drilling job in wood, plastic or metal surfaces with this amazing Milwaukee Teeth Aluminum Cutting Circular Saw Blade.

In stock

Description

The Milwaukee 9 in. 72T Aluminum Cutting Metal Circular Saw Blades are specifically designed to exceed contractor’s expectations for blade life, cut quality and speed in the most demanding metal cutting applications – without a lubricant. The metal cutting circular saw blades have hand-tensioned hardened alloy steel bodies. This extends blade life and delivers the highest quality cuts available. The blades have Carbide-Tipped Teeth with Alternate Top Bevel grind to shear through metal delivering burr-free, cool-to-touch cuts.

- Engineered with cobalt infused tungsten carbide to extend cutting life

- Laser cut vibration dampening slots to minimize heat, sound and noise

- Ideal for dry metal cutting

- Cuts cooler for immediate handling and less down time

- Designed to provide clean cutting and a burr-free finish

Additional information

| Weight | 1.58 lbs |

|---|---|

| Dimensions | 0.28 × 11.81 × 13.77 in |

| Arbor Size | 1in |

| Color Family | White |

| Material Cut | Metal |

| Model | 48-40-4355 |

| Number in Package | 1 |

| Number of Teeth | 72 |

| Power Tool Accessory Type | Circular Saw Blade |

| Saw Blade Diameter (in) | 9 |

| Saw Blade Material | Carbide |

| Tools Product Type | Power Tool |

Reviews (60)

60 reviews for Milwaukee 9 in. x 72 Carbide Teeth Aluminum Cutting Circular Saw Blade

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

Model# DW3795HSaw Blades

DIABLO 10 in. x 80-Teeth Non-Ferrous / Plastic Cutting Saw Blade

Model# D1080NSaw Blades

DIABLO 7-1/4 in. x 24-Teeth Tracking Point Framing Saw Blade

Model# D0724RSaw Blades

Milwaukee 44-7/8 in. 10/14 TPI Bi-Metal Deep Cut Portable Band Saw Blade

Model# 48-39-0550Saw Blades

Model# D1040XSaw Blades

DEWALT Bi-Metal Reciprocating Saw Blade Set (15-Piece) with Tough Case

Model# DW4890Saw Blades

Model# 48-00-8788Saw Blades

Model# D1060X

Brielle Crooks (verified owner) –

The Milwaukee 7” 54 tooth saw blade is sweet! I wasn’t sure what I had until I tried it, and wow! This blade will cut brass, copper, plastics, fiberglass, and aluminum! It cuts clean (like butter), cuts cool, and dry with hardly any vibration! Load it into a 7” circular saw and you’re good to go. The teeth are cobalt infused tungsten carbide. It definitely needs to be a part of your saw blade arsenal.

Alayna Hackett (verified owner) –

I needed to cut some aluminum shower door hardware as part of a bathroom upgrade. Due to the size of the pieces and type of cuts to be made, I used this blade in my 10-inch table saw. This blade is for a saw with a one-inch arbor – but since my saw has a 5/8-inch arbor I had to use a brass adaptor.This blade seems to be top quality. The carbide-tipped teeth have an alternate top bevel grind, and there are numerous laser cut vibration dampening slots to minimize heat buildup and noise. It is designed to cut without any water or oil lubrication, which eliminates the hassle and mess.This blade worked flawlessly on the parts I cut and produced a fairly smooth finish. I am very satisfied with the quality and performance of this blade.

Rudy Douglas (verified owner) –

The Milwaukee seven and a quarter inch (7 ¼”) by fifty-six (56) tooth carbide metal cutting circular saw blade is capable of cutting brass, aluminum, fiberglass, copper , vinyl, and any nonferrous metals up to a quarter inch (1/4”) (6.4 mm) thick. WEAR SAFETY GLASSES! as this does throw minute shavings. One note is that the cut material is not hot to the touch after cutting and no oil is required during cutting operation.

Ruthe Murazik (verified owner) –

I have been using this blades for the last 10 years and they work excellent.

Camilla Osinski (verified owner) –

So far so good. I’m not used to using a carbide tooth blade to cut metals. Usually I use the old style abrasive blades or wheels. But I’m definitely liking the carbide tooth blade mush better. Milwaukee made some pretty good blades here. I used the blade to cut some copper pipe, aluminum sheeting and some fiberglass panels and all worked out great. For the copper it was really fast and the metal stayed cool. It didn’t heat up or spark like crazy. The aluminum sheeting cuts were perfect also. Actually surprised how there wasn’t many burrs if any at all when I had a good straight line going. I also cut some thin metals on some blinds to cut the track to size and it sure beat using a hacksaw. I really like how clean this blade cuts with no burrs or burn marks. Definitely wear eye protection because little flakes of metal can jump around depending on the saw. I used it on my Milwaukee 6 1/2 saw and the rpms suited it well. All the carbide teeth are still there after me using it and still sharp. Definitely looking forward to using this style blade now to cut metal. Hopefully Milwaukee makes some 1/8” thickness metal cutting blades in the future for some softer steel. Definitely good quality carbide material used in this blade.

Shanny Lockman (verified owner) –

I was attempting to cut plastic panels with the 40t ‘construction’ blade that came with my saw. I knew better from the start but it was worth the experiment. In the first few inches you could tell the edges were going to be rough and chipped and just not great. Fortunately this blade showed up shortly after and the difference was night and day. Quick, clean cuts. Much smoother edges. All around a great experience. I’ll be really curious about aluminum or copper performance, but so far so good.

Russell Franecki (verified owner) –

The Milwaukee 7-1/4 in. x 56 Carbide Teeth Metal Cutting Circular Saw Blade makes short work of cutting aluminum flashing. I am using the used flashing for some lawn edging and needed to cut a few inches off a piece. This blade cut it off as it was nothing. As with a lot of tasks, the prep and cleanup was way more time consuming than the task at hand. When I selected this blade, I had hoped to use it on some steel roofing sheets. When it came, the first thing I saw was “ALUMINUM” in big letters. Only slightly disappointed. It will get plenty of use on other aluminum and possible cement board siding provided it is suitable for that.

Jane Hand (verified owner) –

Great blade cuts right through steel I use it to cut the bolts cuts with no problem

Lavern Zemlak (verified owner) –

This is a high-quality Milwaukee 5-7/8 in. x 50 Teeth Non-Ferrous Metal Cutting Circular Saw Blade for cutting aluminum, brass, copper, plastics, or fiberglass. This carbide blade can cut medium thick material 1/16 to ¼ inch thick. It can be used with the Milwaukee cordless handheld circular saw. It has cobalt infused tungsten carbide teeth and laser cut vibration slots.

Sister Parisian (verified owner) –

So I ordered this new blade for my metal cutting saw since it says “metal cutting circular saw blade” I use a heavy duty metal cutting blade for cutting STEEL. Glad I looked closely at the blade. Afraid to try it on steel so I used it for cutting a 1″ round stock aluminum rod. It cut nicely but I am just going to save it for the occasional cutting of soft metals. Milwaukee should re-name it ‘SOFT METAL CUTTING BLADE” I cut 100 pieces of steel for every aluminum or brass piece I cut. Nice blade, just not what I thought it was.

Laurence Thompson (verified owner) –

I ordered this blade to cut a number of different materials including plastic pipe. In the past I’ve done it with just a regular carbide blade with good results. In this case, I needed to get a better cut for my current project, not actually plumbing but building a drone, so I ordered this 10 inch metal cutting blade to use on my compound miter saw. It really allows for a precise cut even on larger diameter pipe.One word of caution, using this blade on any material generates a large amount of very fine dust. I was shocked @ how much floats around during the cutting process; wear good safety glasses.

Virginie Harris (verified owner) –

Milwaukee 48-40-4370 14” 80 Tooth Carbide Circular Saw Blade – This Circular Saw Blade has Cobalt infused Tungsten Carbide, the blade is designed to be operated at 1800 RPM and installed on the Corded Metal Cutting Miter Saw…This blade is rated to cut medium thickness 1/16” to ¼” Aluminum, Brass, Copper, Fiberglass and Plastic, it will also cut thin up 3/32” Steel and medium 1/8” to ¼” steel…The blade has been designed to cut dry (no lubricant required) as well as cut cooler…I installed this blade on Milwaukee # 6190-20 Dry Cut Machine, this blade runs and cuts with less vibration due to (4) groups of equally spaced laser cut slots…I cut ¾” Grade “L” Copper Pipe, ¾” EMT, Aluminum Rain Gutter, 4” PVC Conduit and 7/8” Galvanized Super Channel…The blade performed as indicated, intended and expected without any problems…According to Milwaukee this blade is not rated to cut any metal thicker than ¼”…Milwaukee does manufacture (2) blades to cut metal up to ½”, a 72 tooth blade # 48-40-4505 and a 90 tooth blade # 48-40-4510, both blades are designed to be operated dry on a corded metal cutting miter saw…These blades produce burr free cuts on threaded rod or bolts…

Dereck Kiehn (verified owner) –

My impression of this saw blade is excellent. I received this and put it into my portable saw, which worked as the blade is 6 1/2,” and my saw is made for a 7 1/4″ saw blade. I wanted to see if the battery saw would cut through a steel door. The advertising on the package states this blade will cut brass, copper, plastics, fiberglass, and aluminum! What is doesn’t say is it will cut steel. Well, they missed that when they printed the label because I installed a new door for a customer and decided to try to cut her old steel door so it would fit in her trash can. It cut like butter, with a beautiful smooth cut line. Word of warning, though, wear goggles because it will spray metal shavings at you. I expected some shavings but not as much as was sprayed at my face and chest. Do not attempt this without face protection. This is my new go to metal cutting saw blade.

Rita Batz (verified owner) –

I love these 8 inch blades. This 58 tooth gives you smooth, fast cuts in aluminum, plastics, fiberglass, copper and brass. It’s excellent for cutting sheets of aluminum or fiberglass, as it cuts cleanly and doesn’t heat up like some. With more plastics being used, this works great for making smooth accurate cutting there too. The teeth are ‘cobalt infused tungsten carbide’ and no lubrication is needed. It didn’t clog up with material like some I’ve used in the past. This is perfect for my 8 inch metal saw. If you have an 8 inch metal saw, why not use an 8 inch blade? If you haven’t tried these newest blades, give them a try. They perform flawlessly and save time too.

Alysha Gulgowski (verified owner) –

This Milwaukee Metal Cutting Saw blade actually needed to list Non-Ferrous Blade in its listing. As for its cutting ability it is actually very good for aluminum, copper, brass, fiberglass and most plastics. For a 14-inch blade with a 1-inch arbor it will fit a chop miter saw or a powered cut-off saw. The cut-off saws now come in gas or battery powered units. If you are working in an aluminum fabrication shop this would be a must have because the cuts are that clean, needing no additional preparation to go to the TIG welder. The other materials are generally cut by miter saws only in pre-fab home construction on a demanding basis that would call for this blade. In my case using a blade like this with such a narrow material base does not compare. There are too many blades in this size range that will cut all of these materials PLUS ferrous metals (iron & steels), along with woods. The pictures below would have shown a complete comparison of the blade cuts; however, my neighbor took his Aluminum and Copper blocks that were cut back before I hand a chance to get the picture, due to a call back to work. The cuts were however, extremely clean for both saw blades. This blade is an excellent choice for the fabrication professionals who do not use wood or ferrous metals. For that reason and those areas only would you find this blade an excellent choice.

Isaias Considine (verified owner) –

I have been a builder and remodeler for 50 years, and as such I have had many occasions where I had to cut aluminum and plastics. But while I could use other blades like a wood blade or others, often it is better if I an just use the blades made to cut the material. For example, this MILWAUKEE 10 IN. X 80 CARBIDE TEETH METAL CUTTING CIRCULAR SAW BLADE. I recently used it to cut some aluminum and also some PVC trim, and it cuts cleaner and easier than a wood blade.

Sunny Williamson (verified owner) –

Great blades, too bad these aren’t available in store EVER!!!

Danielle Treutel (verified owner) –

9 in. Carbide Tooth Metal Circular Cutting Saw Blade. Designed for softer metals, aluminum, brass, copper and plastics / fiberglass. Fairly thin blade. I’ll use mine to do some wood cutting. This blade has 72 teeth. Arbor size (center hole) is 1 in. I’ll need a 1 in to 5/8 in. adapter to use it on my saw. If you are going to store the blade, I’d modify the original plastic packaging and store the blade in that. Will protect your hands from the sharp teeth.

Novella Herman (verified owner) –

I ordered this blade to cut down some old metal picture frames myself instead of taking them to a picture frame shop & spending almost as much money as the price of this blade. Seems that I can now do this myself with near professional results. More than likely I’m the only one that could tell it wasn’t done professionally. One word of caution, using this blade on any material generates a large amount of very fine dust. I was shocked @ how much floats around during the cutting process; wear good safety glasses.

Jerad Wisoky (verified owner) –

This Milwaukee 9” diameter 72 tooth aluminum cutting blade powers through 3/16” aluminum like cutting through wood. The resulting kerf is precise, clean and smooth. I also cut a piece of 3/8” Plexiglas. The cut was as precise and clean but with a minor amount of spalling along the edge on one side. It is possible that a slower feed might reduce that. I do not own a hand held saw with a one-inch arbor or for that matter a hand held saw that can accommodate a 9” blade. I used this in a corded 10” bench saw with a 5/8” to 1” adapter to clean up some scrap to try it out with great results. In the past I have used either a jigsaw or reciprocating saw to make these cuts and then had to clean them up by filing or grinding. Very difficult to get a long smooth straight cut that way. This is a very nice and welcome addition to my workshop. One negative is the packaging. It definitely protects the product – with vigor! It would have been nice if the packaging could be more easily reused for storage between uses. It is very difficult to initially remove the blade from the package and getting the blade in and out through the opening made in the back of the package is difficult when using it for storage.