Milwaukee 1-3/8 in. Carbide Universal Fit Extreme Wood/Metal Cutting Oscillating Multi-Tool Blade (2-Pack)

$31.46

Perform your difficult tasks effortlessly with the selection of this highly durable Milwaukee Carbide Universal Fit Extreme Wood Metal Cutting Oscillating MultiTool Blade.

In stock

Description

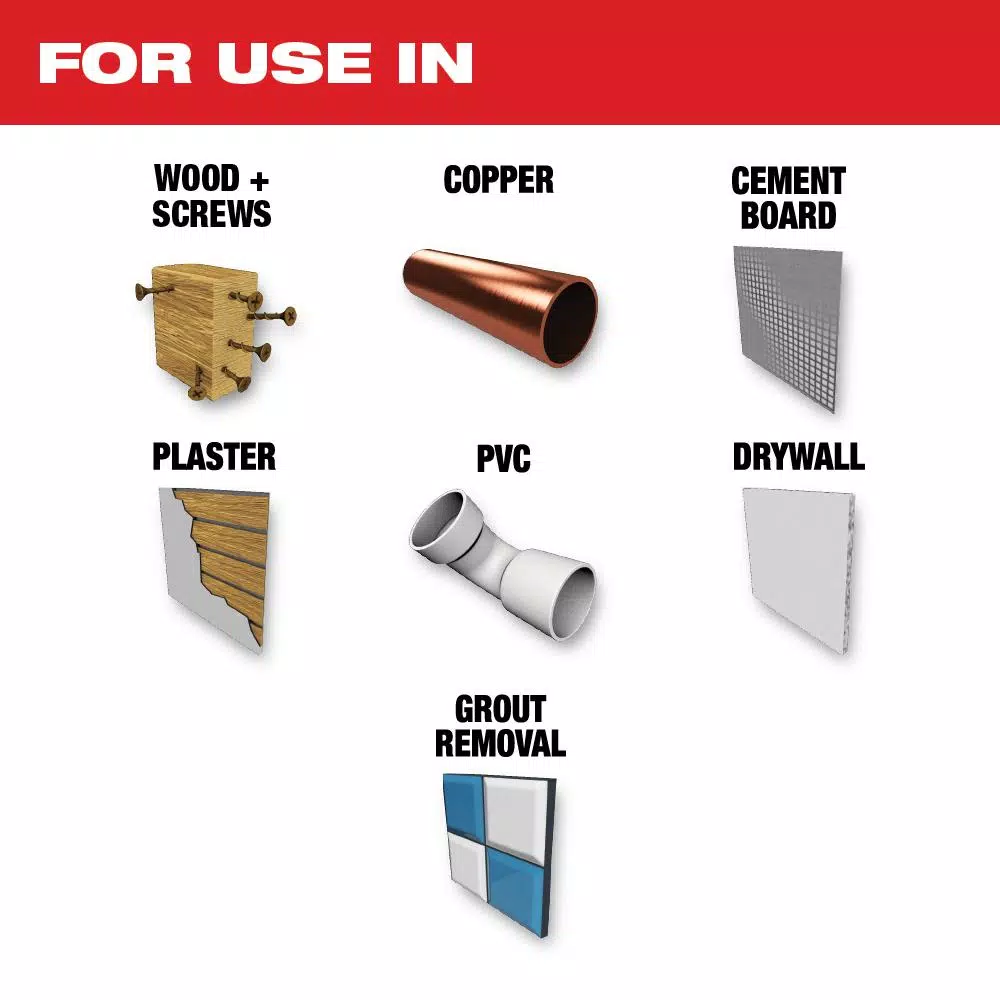

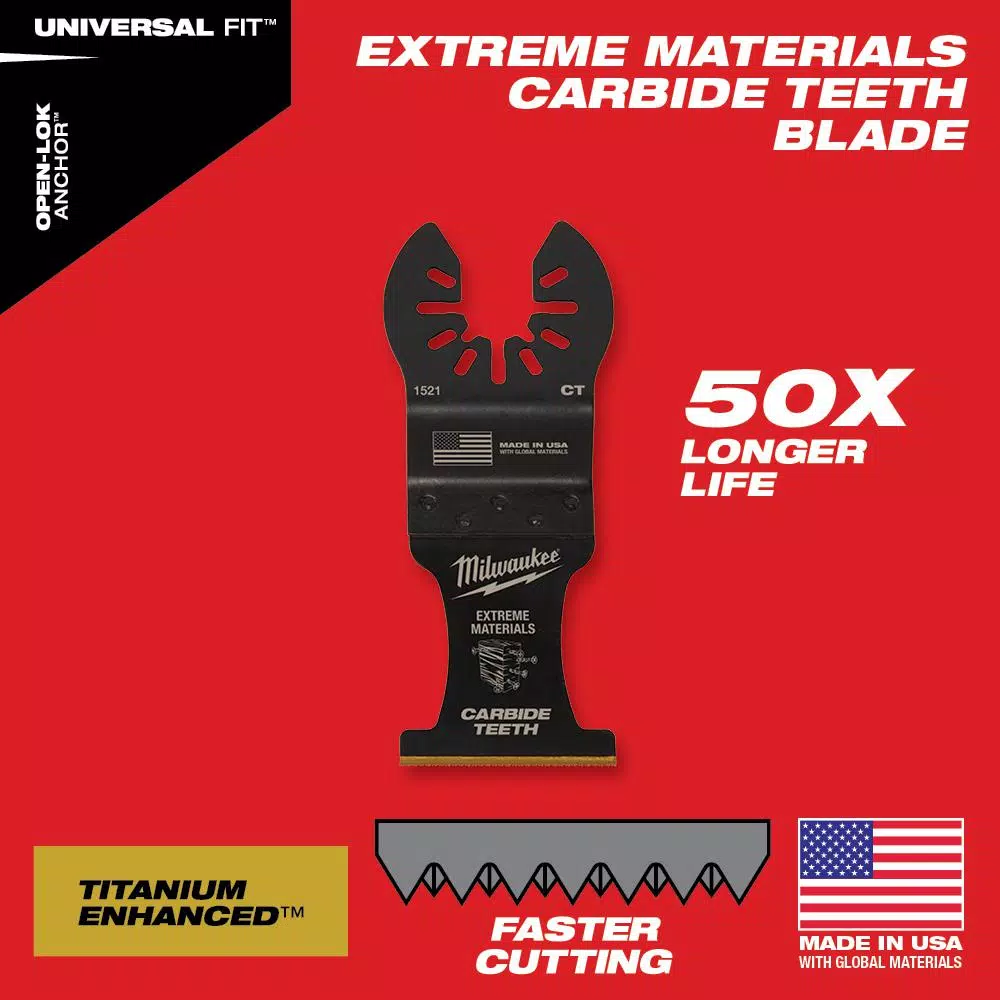

The MILWAUKEE Universal Fit OPEN-LOK 1-3/8 in. Titanium Enhanced Carbide Teeth Extreme Material Blade 2 Pack is designed for Oscillating Multi-Tools. It has a unique aggressive tooth design that offers users optimal cutting performance in wood, screws, metal pipe, nails, cement board, plaster, and more. The 1-3/8 in. Titanium Enhanced Carbide Teeth Extreme Material Blade lasts up to 50X longer than standard bi-metal blades and can be used in a wide range of materials for the longest blade life. The unique, aggressive carbide tooth design offers faster cuts and better cutting performance in wood when compared to standard carbide blades. These Milwaukee multi-tool blades are designed with global materials.

- Universal fit OPEN-LOK Anchor for quick blade changes

- Titanium enhanced carbide teeth for up to 50x longer life

- Unique aggressive carbide teeth design for faster cuts

- Ideal for extreme material cutting in wood & screws, metal pipe, nails, cement board, plaster and more

- Titanium enhanced to extend blade life

- Raised Open-Lok Anchor for flush cutting

- Cut-away blade body shape for fast plunge cuts

- Protective black oxide coating with long lasting laser etching for clear and easy blade identification

- 1-3/8 in. Cutting width and 1-1/2 in. Max plunge cut depth

- OMT unique aggressive carbide

- OMT made with global materials

- OMT extreme materials

- OMT 2-pack

- Includes: one 49-25-1522-1-3/8 in. carbide teeth wood blade 2-pack

Additional information

| Weight | 0.15 lbs |

|---|---|

| Dimensions | 0.60 × 3.88 × 6.38 in |

| Accessory Fitment | Universal |

| Application Type | Cutting |

| Blade Material | Carbide |

| Color Family | Black |

| Model | 49-25-1522 |

| Number of Pieces | 2 |

| Oscillating Tool Attachment Type | Blade |

| Power Tool Accessory Type | Oscillating Tool Accessory/Part |

| Product Length (in.) | 3.58 |

| Tools Product Type | Power Tool |

Reviews (7)

7 reviews for Milwaukee 1-3/8 in. Carbide Universal Fit Extreme Wood/Metal Cutting Oscillating Multi-Tool Blade (2-Pack)

Only logged in customers who have purchased this product may leave a review.

Related products

Oscillating Tool Attachments

Genesis Universal Adapter for Fein Supercut Oscillating Tool

Model# GAMT404Oscillating Tool Attachments

Model# GAMT531TOscillating Tool Attachments

Genesis Universal Quick-Fit Flush Cut Blade Assortment Pack (3-Piece)

Model# GAMT501Oscillating Tool Attachments

Model# MM900Oscillating Tool Attachments

Genesis Universal 1-3/8 in. Precision Oscillating Multi-Tool Quick-Release Flush Cut Blade

Model# GAMT514Oscillating Tool Attachments

Model# A24JM03Oscillating Tool Attachments

Bosch 1-1/4 in. Bi-Metal Precision Japanese Tooth Oscillating Tool Blade for Cutting Hard Wood

Model# OSC114JFOscillating Tool Attachments

Model# 63717082033

Adrian Douglas (verified owner) –

Fits most oscillating tools. This will sit flush and has a plunge depth of 1-1/2″ (38 mm). It has carbide teeth designed to cut wood with embedded nail/screws, copper pipe, cement board, and plaster. I tested this blade by driving a roofing nail into a piece of poplar wood scrap. I also partially drove another roofing nail and a galvanized nail into the wood. Both nails cut off quickly and cleanly. The wood with embedded nail cut with no problem. This blade could be the perfect option for separating 2 pieces of wood held together with nails or screws. I thought that maybe removing door frames from rough openings is possible – if you don’t have a reciprocating saw. This is Milwaukee part 49-25-1522.

Robbie Hauck (verified owner) –

Cut through metal like butter, noticeable wear on the teeth after a few screws/nails. But still sharp

Gay Denesik (verified owner) –

Milwaukee 1-3/8 in. Carbide Universal Fit Extreme Wood/Metal Cutting Oscillating Multi-Tool Blade (2-Pack)You cannot go wrong when you get Milwaukee cutting blades. I really like that they will fit all the different Oscillating tools. The blade is very high quality & 1-3/8 in. Cutting width and 1-1/2 in. Max plunge cut depth. I have used this when trimming a small amount on my gate when I had one board that was hitting the new pavers I had put in. This blade made very quick work of the job. This blade is perfect for offset plunge cuts and very durable.

Orlo Walter (verified owner) –

Pleasantly surprised. The blade that came with my Ryobi multi tool would not cut vinyl shelves (ruined the blade within 3 cuts), so I decided to use this one. After about 24 cuts, which went smoothly, it still seemed fine.

Wilbert Hettinger (verified owner) –

I have a Bosch carbide oscillating saw blade so I compared the Milwaukee to it. I cut a scrap piece of 3/4 by 1/8 steel with each blade. The new Milwaukee was done in 30 seconds and the Bosch took 45. But the Bosch is well used and the Milwaukee is new. So within the accuracy of this test I would call it a tie. Both cut MUCH faster and longer than a bi metal blade would. If you are doing what I normally do and are just cutting a nail or bolt it will take only a few seconds. As you can see, it fit my Fein well.

Jamal Abshire (verified owner) –

These Milwaukee 1-3/8 in. Carbide Universal Fit Extreme Wood/Metal Cutting Oscillating Tool Blades are good to have. They are universal fit for about any oscillating tool, and even include an adapter for some of the Dremel tools. The Titanium enhanced carbide teeth will cut just about any material including wood, and the nails, screws, etc. found in it. Additionally, they will cut through cement board, plaster, and metal objects like pipe, etc. often found in remodel projects. They should outlast other bi-metal type blades. Since the teeth are carbide, they are quite hard (brittle), requiring care to prevent breakage. In my test cut on old copper pipe, I made the mistake of using too high speed. One slip was all it took to break off several teeth. Overall though, I think, with care, these blades will be worth the cost.

Geovanni Fahey (verified owner) –

I consider this is a specialty blade. It has carbide teeth, very fine major and minor tooth spacing, and it has undercut sides, a design that allows the blade to perform well in unusual situations and on hard materials. The packaging says the blade is ideal for wood screws, cement board, copper, pvc, plaster, drywall, and grout removal. I used it to easily cut off a ss hidden deck fastener screw that was stripped. Since it was already in my multitool, I used it to make some cut-outs in composite decking—which I do not recommend. It does not cut cleanly and the material gums-up the small teeth. I used it successfully on ½” copper tube where it left a very small burr. Although it is labeled for PVC, I would not recommend it for either PVC or CPVC—see photos. The label did not mention brick, but I found that it worked well and cut relatively quickly.The blade fits most multitools except those with a STARLOCK head. It even fits Dremel models with the included adapter.As the teeth are very small, I wondered what the actual count is as there is no information on the package. After several counts, I believe that there are 35 major teeth. I say major because there are also smaller and shorter teeth between the larger ones. With a blade width of 1-3/8” (35 mm), the major tooth count is 25/inch (10/10 mm). Counting the shorter teeth would double the count. The blade is made in the USA.