SKILSAW 7 in. 15 Amp Corded Medusaw Aluminum Worm Drive Circular Saw for Concrete

$350.09

SKILSAW Corded Medusaw Aluminum Worm Drive Circular Saw for Concrete is designed specifically for scoring and cutting concrete accurately.

In stock

Description

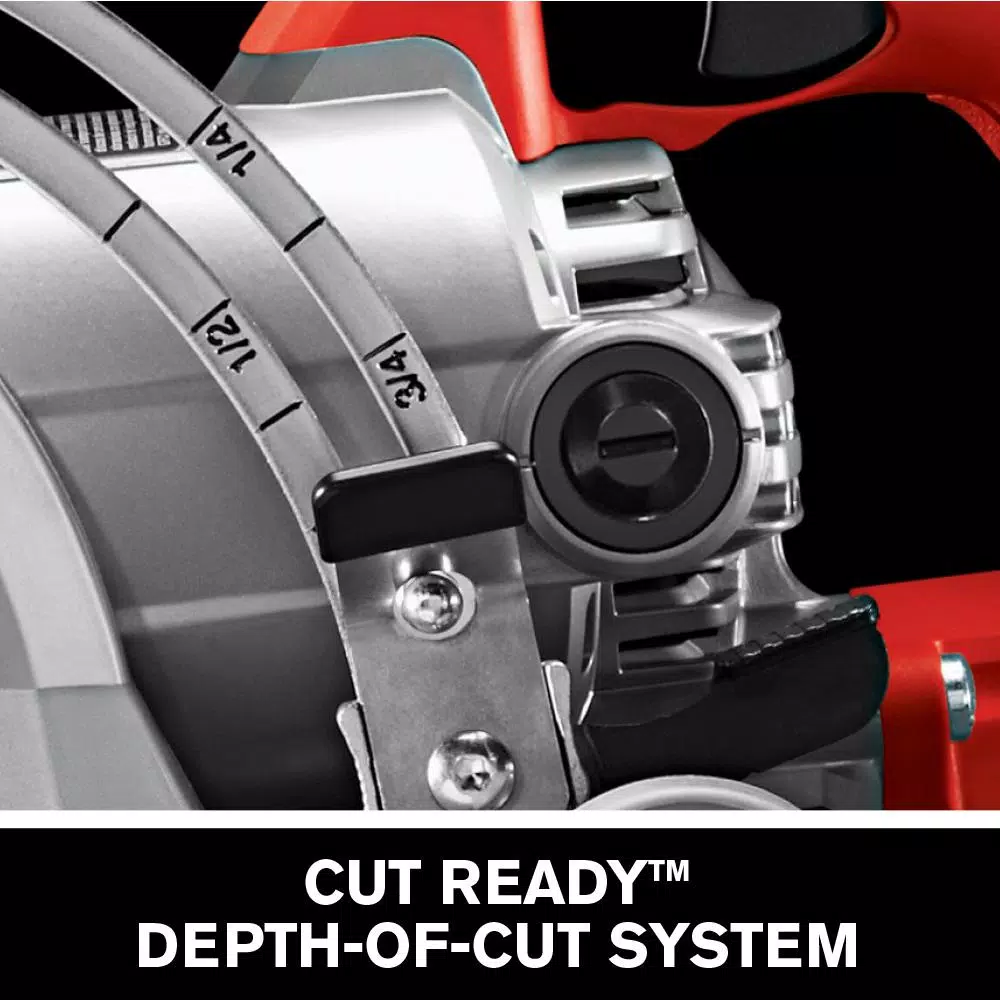

When there’s concrete to conquer, MEDUSAW makes the job a whole lot easier. It’s the world’s first fully integrated saw designed specifically for scoring and cutting concrete accurately. Forget modifying an old saw. This one’s got our legendary SKILSAW worm drive power train, plus a unique Cut-Ready adjustable plunge lock and a pivoting pointer for unmatched precision and convenience. Used wet or dry, the dual integrated dust management system takes dust out of your way. And rust resistant brackets and fasteners resist corrosion for long life. Armed with MEDUSAW, you’ll power through the toughest concrete jobs. It’s all part of the performance legend that is SKILSAW.

- Wet/dry dust management system controls dust for cleaner cuts and longer tool life

- GFCI protection reduces rick of shock to user

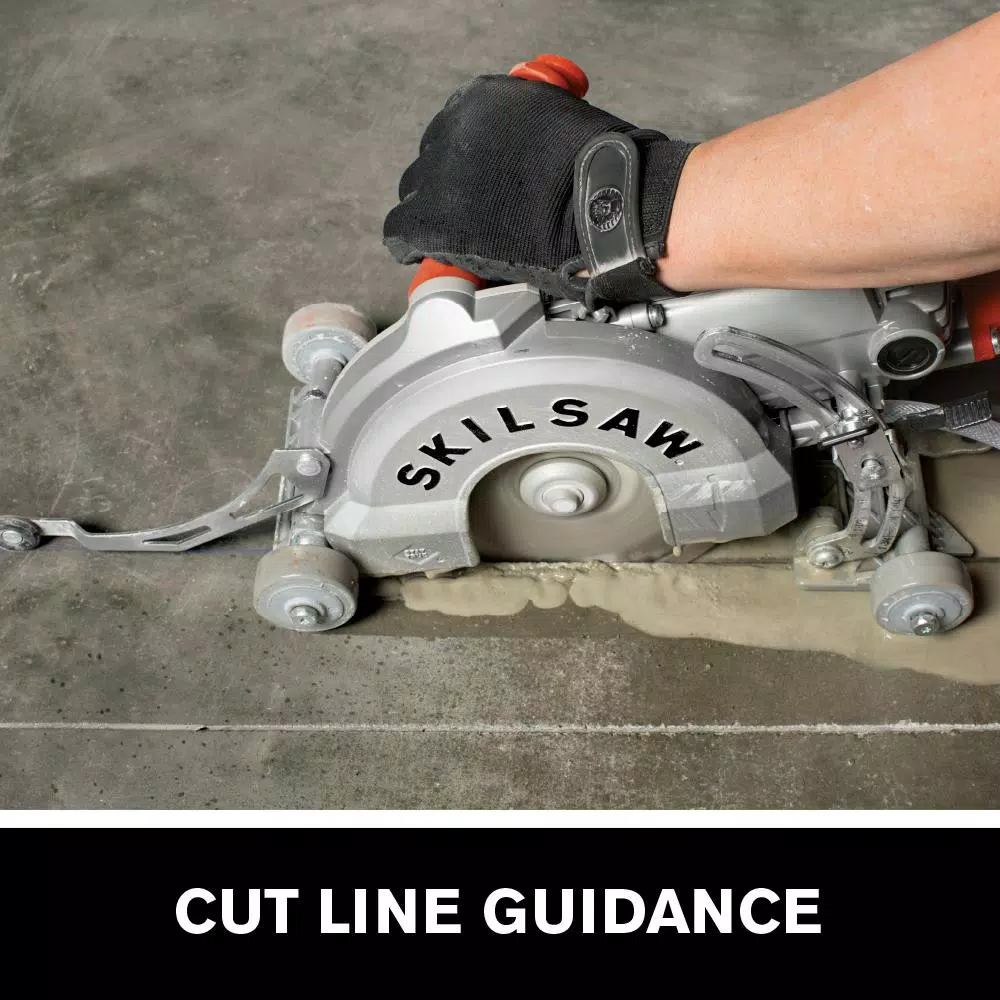

- Retractable front pointer guides saw along cut line and retracts for tight spaces

- Integrated rolling foot plate with rubber wheels allows saw to move smoothly across concrete surfaces

- Powerful dual-field motor increases cooling and extends tool life

- Multi-function wrench stored in foot designed to easily change blades, brushes, water feed attachment and wheels

- Includes: SPT79 SKILSAW 7 in. Medusaw worm drive for concrete, vacuum hose adapter with clamp, water feed assembly and multi-function wrench

Additional information

| Weight | 16.9 lbs |

|---|---|

| Dimensions | 21.50 × 9.00 × 9.00 in |

| Amperage (amps) | 15 A |

| Cuts Through | Concrete |

| Saw Drive Type | Worm Drive |

| Power Tool Features | Depth Adjustment, Keyed Blade Change |

| Model | SPT79-00 |

| Maximum Speed (rpm) | 5100 |

| Maximum Cut Depth @ 90 Deg. | 2 in |

| Maximum Cut Depth @ 45 Deg. | 0.0 in |

| Included Accessories | Tool Only |

| Depth Adjustment | Yes |

| Cordless/ Corded | Corded |

| Bevel Capacity | 0 |

| Corded Tool Type | Circular Saw |

| Cord Length (ft.) | 10 |

| Construction Material | Aluminum |

| Condition | New |

| Color Family | Red |

| Blade Location | Left |

| Blade Diameter (in.) | 7 |

| Blade Diameter | 7 |

| Tools Product Type | Power Tool |

Reviews (36)

36 reviews for SKILSAW 7 in. 15 Amp Corded Medusaw Aluminum Worm Drive Circular Saw for Concrete

Only logged in customers who have purchased this product may leave a review.

Related products

Saws

Model# 6480-20Saws

Model# DW317KSaws

Model# DW716Saws

Model# D28715

Genesis Larson (verified owner) –

We recently received our Medusaw concrete saw and tried it out on a slab of seamless slate textured stamped concrete. The first thing I noticed is the aesthetics of the saw are very nice. I know that may not seem important, but when you’re trying to present a professional image to your customer, it does make a difference. It also helps your crew members want to take better care of the saw. The really nice thing about this saw is that it comes accessorized with a vacuum attachment, a water attachment, a rolling foot plate and a pointer. No need to buy aftermarket accessories and adapt to your Skilsaw. I’ll discuss each accessory individually. First, the vacuum attachment. We hooked the saw up to our Greenlee 690 107cfm vacuum and made a 13′ x 1/4″ deep cut. The vacuum attachment seemed to work well but there was a small amount of dust that escaped through the front of the saw. With the new stricter OSHA silica dust rules, this could be a problem. Perhaps a more powerful vacuum would mitigate this issue, we’ll have to do some more testing. It took about 3 minutes to make this cut. Not bad at all. Next we tried the water attachment and made a 13′ x 1″ deep cut. The water attachment has a handy little shut off valve conveniently located near the handle of the saw. The first thing we noticed is that when we turned on the water, it leaked out pretty badly at the attachment end. There is a hose clamp there and after a quick tightening with a screwdriver, it stopped the leak. Be sure to check this clamp before you use the saw. The wet cutting virtually eliminated all dust and I was impressed with how little slurry it created. I think that in order to meet the new OSHA standards, the wet cutting is going to be the way to go. It does take a little more labor to vacuum up the slurry and dispose of it, but it’s better than an OSHA fine, plus it will help your blades last longer. Speaking of blades, we used a fairly inexpensive, generic undercut blade (about $50) for this test. We tried using the vacuum attachment along with the water attachment to see if it would pick up any slurry, but it didn’t, so don’t bother. This cut took about 5 minutes to make. Again, not too shabby for a 1″ deep cut. The rolling foot plate seems to be constructed well and performed nicely but I did notice that the wheels are made from a hard plastic so I worry about them breaking. The pointer is one of the best features of this saw. We snapped a line and only used the pointer, no straightedge or guide. We checked it with a string line and found the cut to be almost perfectly straight! Remember, these cuts were on a stamped textured surface, not the easiest to maintain a straight cut on. We didn’t try it, but I think this saw would work well on radius cuts as well, as long as the radius isn’t too tight. Overall, I think this is a great saw for the money and I’m sure I’ll purchasing several of these in the future. The only negative thing I can say is that our saw didn’t come with a case and I don’t see on Skilsaw’s website where they offer one. We went to the local hardware store and bought a generic case, but it would be nice to have it come with a case. Happy cutting!

Dallin Mraz (verified owner) –

I got the Medusaw to cut the control joints in floors and small concrete pads, the saw comes with items and features that would have to be purchased and attached to saws for more cost. After using this for the first time I was very pleased with the results. The saw with the guides and wheels made it easy to useThe attachment for a vacuum can be connected with either a 1-7/8″ or 2-1/2″ vacuum hose that are a standard with all shop vacuums worked really good, the only dust I saw was by the blade being drawn up into the upper blade guard and into the vacuum.The water feed assembly is easy to attach and use. I have always cut with a dry saw and it is nice to have no dust. The water keeps the blade cool and cuts faster. The water valve is close to the saw to turn on and off also control the water flow easily with the valve the assembly has a quick connection that can be attached to any garden hose.Cutting lines was very easy with four different spots on the saw for guides the front guide folds down or can be folded up and held in place by the magnet that is part of the upper guard the rear line guide on the foot is another great reference point to keep lines straight and the foot with the solid wheels rolled smooth.The depth adjustment that can be set to a determined depth is unique and I liked that . After I set it were I wanted I made the plunge cuts at the start of the lines it locked in place cutting the line and at the end can be released with one hand easily and the plunge spring raises the saw up out of the cut until the saw stops.My overall experience is that this is a great tool for the price, it delivered a quality clean cut lines that in my opinion is as good as gets .

Jeffery Rice (verified owner) –

It makes work so much easier! From relief cuts, control joints, decorative cuts, or removing bad concrete in tight spots for repair, this saw is the real deal! Wet or dry, it’s definitely better than having to use a cut off saw! It allowed me to remove damaged concrete around support pillars to re pour and build stone bases in half the time!

Karley Marquardt (verified owner) –

I had an old setup similar to this that a friend loaned me. It was put together from a kit bought seperately. This works as well or better than that saw straight out of the box. I did find the water feed a bit spare for my tastes and maybdrill the holes out a bit bigger.

Darrin Dickinson (verified owner) –

The saw is built and designed well. I do believe the swing alignment arm could be a bit more stout. I can see where frequent use and abuse would cause misalignment. We used a blade by skil as they were on sale at Lowes for $7.00! When we first turned the water on we realized that the hose clamps were not tight and our ankles took a spray bath. A few quick screwdriver turns and all was resolved! Now for the moment! Let me tell you this little machine will rip thru reinforced concrete with very little to no effort. I typically use more effort pushing a saw when I am cutting wood! You could tell the saw was not straining the least bit! I would love to see this saw modified to accept a 10 inch blade! I believe it could handle it with no problem. I was totally amazed by this little saw in red and silver!My only disappointment is the depth of cut. With a 7″ blade I would hope to get more than 1 1/2″ depth. If the wheels could be raised by 1/2″ ,a 2″ cut could be acceptable. With a 10″ blade you should be able to slice thru a 3″ sidewalk with no problem. We recently purchased a home that we will be installing a scored and stained concrete floor. I know this machine would be perfect for scoring lines in the existing concrete! Skil has definitely come up with a medusa in concrete saws! Now for a 10″, please! And I am ready to test it

Mallie DuBuque (verified owner) –

I’ve known about this tool for a while and when it launched I knew it was going to be a winner. I also knew it was out of my budget. When I purchased my worm drive table saw I immediately registered it for warranty purposes than also checked a box. That box was if I wanted to hear about new tools and promotions. So when it was contacted about being eligible to be a tool tester for this saw I filled out the entry form and won. I not giving a biased review because of this being a promotional give away cause I don’t want fellow Contractors to buy a product that I wouldn’t use myself. Guys go out and buy this saw! It’s amazingly smooth with all of its features it’s worth every penny. I just wish there was a case so it was safer to transport.

Emmitt Auer (verified owner) –

Wow…I put in a pool with a concrete deck around it. I wanted concrete tile, but could not afford the tile/labor so I had a slab poured. I used the saw to cut lines in the concrete to simulate the tile. I had tried my regular 12 amp skil saw, but it made a huge mess, bogged down terribly and was really slow. The cuts DID look great, but I was dreading cutting 1000 sq. ft of concrete into 24″x24″ blocks. I thought I would try the Medusaw. What a difference! This thing buzzes right through the concrete, glides smoothly on the wheels, distributes the perfect amount of water in exactly the right spots, and does a great job controlling the dust. I was able to make perfectly straight cuts in no time at all (relatively speaking…..it was still a big job). The only accessory I would like to see? A handle that would allow you to stand up and walk behind it! Advice…..be sure to rinse if off when finished. Concrete slurry is difficult to remove once dry.Great job on the saw Skilsaw.Todd

Lisa Hill (verified owner) –

Great saw for it’s size… Would buy again

Tania Stamm (verified owner) –

Good saw but arbor is not standard size so check your blades

Noemy Schinner (verified owner) –

Why didn’t I buy this years ago!!! Thee best concrete saw!!!

Lenny Bayer (verified owner) –

I got this saw and all I can saw is Wow.. The saw is a well built and designed to last. I love the dust management system. I have used this saw on three projects and and five more scheduled . This saw is very versital and me and my guys almost fight to use the saw..lol..We have used it in industrial settings removing grout around a million dollar piece of equipment worked great and completed project ahead of schedule.We use this saw to cut decorative patterns in pool decks,cut stone for firepits all the way to score concrete expansion joints in driveways..Just love this saw! If anyone wants a strong powerful saw and endless possibilities…This is the one…Thanks for producing this tool..O BrittPinehurst NC

Nat Denesik (verified owner) –

The dust collection when dry cutting was excellent.

Whitney Larson (verified owner) –

This is a good product

Marta Swift (verified owner) –

“We got this saw to test out, for various tasks we do. First was removal of an 18″x24″ x 1/2″ deep section of a concrete slab for polishable overlay.We first cut out a perimeter to demo out inside of.Then, we kerf cut multiple times inside the perimeter, to chip out the concrete. The perimeter cut was left very smooth and clean. Then the kerf cuts. Our previous saw would have gotten too hot halfway through. We would have had to stop and let it cool down. The wormdrive Medusaw, had no such issue. It plowed through each cut without a problem. with a little prep with a chipping hammer, we were ready for the overlay.The plunge stop is a great feature to keep each cut the same depth.We dry cut using the dust extractor adapter, hooked up to a 235 CFM, Ermator S26.The vac worked well, keeping air borne dust to almost nothing. Although there was minimal dust left on the floor in front of the saw.The cut was easy to keep straight using the multiple reference points on the saw.The finished cut was super clean.Second Test was for a common repair we do, repairing damaged joints.We usually have to lug around a cumbersome gas powered saw, to make a parallel cut alongside a bad joint. Using the Medusaw was easier and faster. Using the included water feed assembly, we made sequential wet cuts, alongside the joint, as well as inside. The Medusaw worked great, getting to 2″ depth, 1/2″ at a time. No binding or pinching.We removed the bad sections, and layed in our repair mortar (Fast set T45). After the repair mortar cured, we score cut the repair with the Medusaw, to honor the joint. Once again, no issues with the saw. With the 4 cut line references on the saw, keeping the cut on track was effortless. The saw breezed through the cut with ease, and the slurry water was left in a nice stripe which was easy to clean up. It also comes with a built in GFCI, which is a great bonus.The plunge spring seemed to not want to kick up the body of the saw entirely. This will probably get seasoned and broken in, in time. But a little caution is needed, and obviously, let the blade stop before raising the saw.We will add at least one, maybe more of these saws to our tool stock. They are versatile, and tough. Whether or not you grew up with a Skil Wormdrive in your hand as I did, this is a great tool. The sidewinder angle grinder saws we have, will probably sit on the shelf for a while to come.”

Annabell Zieme (verified owner) –

Medusaw ReviewWhat a Fantastic Saw! My old method involved duct taping a hose to the back of my old Skil 77 from when I was in high school in the early 80’s. (I still have it and use it.) The weight kept it on track, the power made it possible to cut the likes of concrete, granite, and refractory. Now, with the Medusaw, no more duct tape, and careful maneuvering while trying to keep from being shocked from the excess water in contact with the saw body and electrical components – it was effective, but lets be honest, it was less than ideal. Testing the saw I chose to score a relief cut in an old, uneven, and pitted section of sidewalk. The Medusaw foot has wheels on the base plate allowing it to glide easily over rough surfaces. My old saw would have been jostled at each and every divot in the uneven walk. The Medusaw easily navigated the uneven terrain. The Medusaw also has a Ground Fault Circuit Interrupter (GFCI) built into the cord. This feature meant that I did not need to run extra cords from a protected bath or kitchen to the saw, or do the mental gymnastics trying to stay ahead of the water and avoid the inevitable shock. The saw has a water feed assembly included with a quick release for a standard garden hose. I can now concentrate on the cut. The extendable cutting line guide with pilot wheel on the new Medusaw made following the snapped chalk line on the walkway easy — it sits out in front of the saw and is therefore highly visible. The old method involved peering around the saw housing at the notch in the base plate and looking at the blades leading edge to stay on course. The excess water from the hose was also always either obscuring the guide marks, or completely washing them away. The addition of the extendable guide arm is a great addition for those long cuts, and my result was a much truer cut than was possible for me before.The Medusaw’s locking depth gauge made the initial plunge-cut easy. With this system the full base is in contact with the work surface and the saw can be prepositioned over the intended cut and simply rotated down into the material, simply and precisely. The old way was to position the saw’s foot perpendicular to the intended cut, and then careful rotate the saw down into the material. This required steadiness and concentration to not waver and create an even entry to the cut; the water was also always obscuring or washing away the layout lines. Plunge-cutting was easy and precise with the Medusaw. The Medusaw’s dust collection port built into the top handle is also a great addition. I tested it without the optional vacuum connection, and simply having the dust directed away from me during the cut made a positive difference. When dry-cutting any reduction in dust generation is a godsend. From my perspective there are three main issues with the dust. • First, is breathing it. Respirators are the go-to solution for that one, but my glasses always fog from either breath escaping around my nose, right to the inside of the glasses, or from additional sweat from the one more layer of protective gear. In the past I have actually resorted to holding my breath during the cut and then escaping the dust cloud to take a breath to avoid the fogged glasses visibility problem. • Second, is the reduced visibility from the dust on the glasses as well as in the air. The process of making a short dry cut in a confined space generates enough dust that visibility nears zero. Occasionally I have to make a dry cut on a vertical surface or overhead where cutting wet is not an option. For me this is usually inside a kiln making repairs. It is like driving in dense fog. Reduction of this dust will greatly increase visibility and safety. • Third, and the last main issue with the dust is clean up. For cuts indoors in a finished space, dust reduction and collection is a really good thing. I could see this collection feature being integrated into the standard classic Skilsaw. For any work on finished indoor spaces dust collection would be would be a fabulous feature.The new Medusaw is a fantastic addition to the Skill 77 lineage. I would highly recommend this saw to anyone doing work with cement products, granite, marble, and refractories.

Elta Bailey (verified owner) –

The thing is awesome! We cut 36″ at 1″ deep in about 15 minutes. Easy set up with wet cutting, easy clean up with minimum water use too.

Britney Koelpin (verified owner) –

I have received saw last week. I have been useing a competitors saw for decorative cuts.For tile patterns, designs and so on on polished concrete. The saw i have been useing is a pain to adjust had to have a unique attachment for vacuum. Had bo eater hook up and the depth on goes up to 3/4 of an inch..Well now thanks to Madusaw i have a saw that can di any and everything in my field.. i wilk definitely be purchasing another for the other crew we have.. and will be recommending this saw to anyone else i come across. Very durable, very well built.. the only concern i have wpuld be guide on front seems a little flimsy. Not necessarily design flaw just knoe hoe things get treated. Thank skil saw

Ebony Kuvalis (verified owner) –

This saw has great power , I was very impressed on how good it cut through concrete. To be honest I didn’t think it was going to cut as good as it did. I will highly recommend this saw to other contractors. This saw cuts through concrete like a hot knife through butter. I also like the water attachment that came with the saw. Thanks again for the chance to review this saw Martinez Construction/General Contractor

Lucio Predovic (verified owner) –

I own the MEDUSAW SPT79 now for close to 6 month and it never bogged down on me, no matter which job or material the saw countered. I used it on cutting concrete driveways, plunge cuts into prefab countertops. I did cut marble, bricks, paver, and concrete blocks. Upon receiving the saw I immediately removed it from the box and noticed it was well packaged and secured. No assembling or fine tuning required. It was ready to use right out of the box. I thought I had to install the rubber wheels but they were already assembled by the factory and protected with a plastic heat shrink. The only part I had to install was a segmented diamond blade, which is not included when you purchase the saw. I used this saw on wet cut and dry cut applications and it performed very well. A vacuum or a dust extractor collects pretty much all of the “dangerous” dust during a dry cut. The included vacuum hose adapter allows you to connect a 1-7/8″ and a 2-1/2″ hose. For wet cut applications you have to install the water feed attachment which can be done with the on board Multi-function wrench (which is stored in the foot plate) with only one screw. It takes less than one minute to assemble or disassemble. The Multi-function wrench is designed to easily change blades, brushes, water feed attachment and wheels. The water feed includes a quick-connect hose adapter with filter for easy removal when you want to relocate the saw and you don’t have to drag the hose with you. The saw creates a perfect slurry and it doesn’t splatter all over you while cutting. Even with the slurry, the rubber wheels glide thru and over the concrete with ease. In my opinion the rubber wheels are good quality…not something cheap what some manufacturers typically use. After a wet cut just hose the saw off, foot plate, blade, blade guard etc and use a damp rag for the top that no water gets inside the saw or parts which can get damaged. The video I will include for this review, shows a 23ft long cut and the saw didn’t get hot at all. The saw has good cooling and enough torque to cut and score concrete without being hard on the motor/gear. As of 6.23.2017 OSHA will begin to enforce silica dust exposure. In my opinion this concrete saw will meet those new regulations in every way due to their integrated wet and dry dust management system. I definitely like the plunge cut feature and the adjustable plunge lock. I used this feature many times for scoring and cutting different materials. The only part I don’t like is the trigger switch which wobbles/shifts sideways. This might be a problem in the long run. I will see how it holds up. A lock-on feature might be interesting/ useful but I am not sure if this will lead to some safety problems. I am very happy with this saw and I am pretty confident that it will last many years.

Sasha Schinner (verified owner) –

The saw worked great. Has great features. Used it to cut just under 1000 liner feet in a new slab.