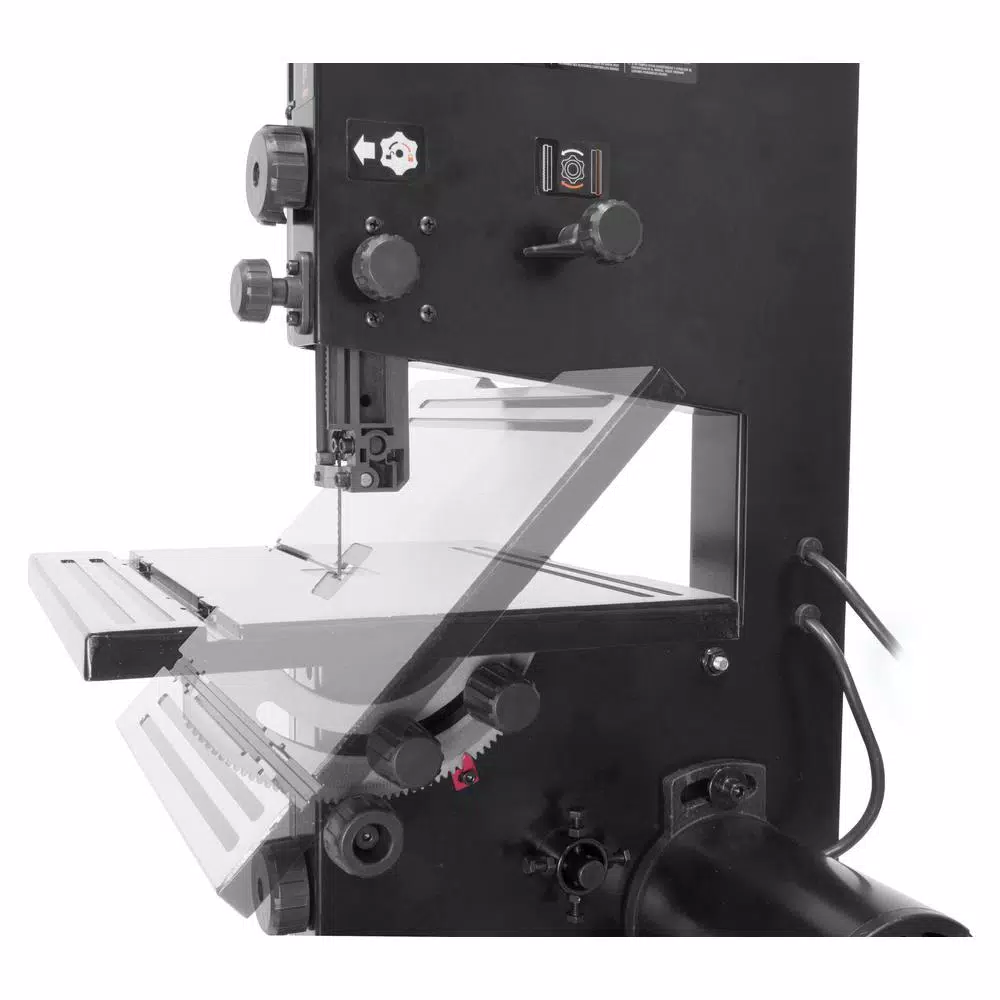

WEN 2.5 Amp 9 in. Benchtop Band Saw

$136.18

Introduce a versatile device to your workstation with the choice of this extra ordinary WEN 2-Benchtop Band Saw. Base is machined to hold the 3 bit set.

In stock

Description

Remember when you had a saw that was both compact and powerful? The WEN 9 in. Benchtop Band Saw attacks boards with cuts up to 3-1/2 in. deep and 9 in. wide. The 2.5 Amp motor rotates the included 1/4 in. blade at up to 2500 ft. per minute. The design of this saw uses 59-1/2 in. blades anywhere from 1/8 to 3/8 in. in width for both intricate and powerful cuts. The spacious work table measures in at 12-1/4 x 11-7/8 in. in size and can be beveled up to 45°. This package includes a miter gauge, an onboard 2-1/2 in. dust port, a fence for creating straight cuts, and an adjustable blade guard. Ball-bearings give the blade smooth operation and a long lasting life for years of dependable service. And because it’s a WEN product, your WEN 9 in. Benchtop Band Saw comes backed by a 2-year warranty, a nationwide network of skilled service technicians and a friendly and helpful customer phone line all to make sure you remember WEN.

- 2.5 Amp motor rotates the blade up to 2500 ft. per minute

- Create cuts up to 3-1/2 in. deep and 9 in. W

- Uses 59-1/2 in. blades anywhere from 1/8 to 3/8 in. in size

- Spacious 12-1/4 x 11-7/8 in. work table bevels up to 45°

- Includes a 1/4- in. wide blade, a 2-1/2 in. dust port, a rip fence and a miter gauge

- Backed by a 2-year warranty

WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov

Additional information

| Weight | 40 lbs |

|---|---|

| Dimensions | 35.00 × 18.00 × 13.00 in |

| Amperage (amps) | 2.5 A |

| Maximum Speed (rpm) | 1720 |

| Voltage (volts) | 120 |

| Tools Product Type | Power Tool |

| Table-Top Material | Aluminum |

| Table Width (in.) | 11.88 |

| Table Tilt Right Max (degrees) | 45 |

| Table Tilt Left Max (degrees) | 0 |

| Table Length (in.) | 12.3 |

| Power Tool Features | Lockout Power Switch, No Tool Blade Change |

| Portability | Bench |

| PT Horsepower (Hp) | 1/3 |

| Model | 3959 |

| Minimum Blade Width | 1/8 |

| Minimum Blade Length | 59.5 |

| Maximum Blade Width | 3/8 |

| Band Saw Type | Vertical |

| Maximum Blade Length | 59.5 |

| Included Accessories | Blades, Miter Fence, Rip Fence |

| Dust Port Size (In.) | 2.5 |

| Dust Collection Method | 2.5 in. Dust Port |

| Cutting Capacity Width / Depth Of Throat(In.) | 9 |

| Cutting Capacity Height / Height under Guide (In.) | 3.5 |

| Cuts Through | Wood |

| Cordless/ Corded | Corded |

| Cord Length (ft.) | 6 |

| Construction Material | Steel |

| Condition | New |

| Color Family | Black |

| Bench & Stationary Tool Type | Band Saw |

| Work Table Surface | 12.3 in. x 11.88 in. |

Reviews (62)

62 reviews for WEN 2.5 Amp 9 in. Benchtop Band Saw

Only logged in customers who have purchased this product may leave a review.

Related products

Saws

Model# DW311KSaws

Model# D28715Saws

Model# 6370-20

Alexandria Dare (verified owner) –

Works will not to hard to set up. Have not had to change blade yet after about 10 hr of cutting plywood.

Luna Langworth (verified owner) –

For a inexpensive band saw, it exceeded my expectations for the use I needed it for it works perfect

Jerome Bergstrom (verified owner) –

Nice saw. Has come in very handy.

Georgiana Hoeger (verified owner) –

Yes

Caleigh Hane (verified owner) –

Great machine for the price. Good for home owner or hobbies !

Humberto Armstrong (verified owner) –

Saw works wonderfully just as I expected. Great even with inch thick cedar….you just have to be patient and work it to your advantage.

Casper Weissnat (verified owner) –

UPS didn’t beat-up the box. I unpacked the saw and everything was in perfect shape. There isn’t much that has to be put together. The table has some Chinese oil or grease on it which has to be cleaned off. I thought the table wasn’t quite as smooth as I would like so a little sanding with 320 grit and 800 grit and some Johnson’s paste made it very smooth. I just tried it out with a couple pieces of plywood and it cuts great, isn’t loud and had no noticeable vibration without it being bolted down. All in all, I am pleased…

Missouri Willms (verified owner) –

Great starter Band Saw. Size and power capability great for DIY. Easy setup.

Dora Fadel (verified owner) –

Lightweight; nonetheless very substantial. Only lack I see is there are no “feet” attached. Several pre-drilled holes permit mounting to a rigid surface. If you prefer isolation pads, they readily can be adapted.Work table is appropriately sized and nicely finished. Locks securely. Good range of tilt. The guide fence can be locked askew. (So you can make a bevel sled for oblique cuts.) Check it with a try square lest you assume it is parallel to blade. The miter gauge is secure and rides smoothly in the rabbeted table. Upper and lower access doors open quickly with cam lock knobs. The power switch is well guarded. Both blade tension and table tilt adjustment have lock-down features. This maintains adjustments reliably.The blade guide adjusts throughout the range of cutting depth. It’s rack gear operation is a plus. This idler permits proper blade face pressure to be applied and maintains the kerf path through the material. It, too, has a locking feature.The lower wheel is fully adjustable and its traction surface appears to be of good quality. The dust collector port is a nice provision.All the knobs are easily manipulated. The safety and dust guards completely enclose the necessary components. All adjustments are readily accessible. The instruction book and parts list is clear. Company contact information is provided.All-in-all, this machine has all the features of the ‘big boys.’I’ve cut softwoods and hardwoods, common plastics and some of the softer non-ferrous metals. I’m anxious to experiment with finer tooth pitch blades (and possibly a rheostat) to extend its use to composite plastics, sheet metal and gasket materials, and perhaps rubber and high density foam.

Violette Trantow (verified owner) –

Love it #!!# Zips right through 2″ Oak like a Hot Knife through Butter , Definately worth the cost. 5 *****

Lyla Blick (verified owner) –

Works great. Fairly easy set up. Hard to open blade guard.

Mathew Considine (verified owner) –

Great tool works very well and good price

Naomie Cremin (verified owner) –

I live it. It’s built better than I thought. Very quiet and cuts smooth. Worth every penny

Ivory Lynch (verified owner) –

Strong and compact, very easy to use and adjust, what took me a long time to finish takes only minutes with the wen band saw, very low price, It is more versatile than my table saw or my miter saw, I should have bought this long ago. One of the best purchases I ever made.

Ocie Moen (verified owner) –

does the job

Henri Walker (verified owner) –

This is a fantastic product definitely worth every penny and has a lot of great features and benefits.

Maybell Bins (verified owner) –

I haven’t had much chance to use it yet but seems ok so far.

Camden Heidenreich (verified owner) –

very easy to assemble, silent and has very good cutting power. It arrived in the scheduled time, very satisfied with the product.

Wilton Beer (verified owner) –

Easy to use and works great!

Kelly Stroman (verified owner) –

The good news:It’s easy to setup. I could have ignored the addendum to the instructions as my blade was already taught. The table assembly was trivial to set up, maybe 3 minutes tops). Everything fit and felt solid. I checked the angles and everything was right without much (if any) adjustments. Looking at how to switch the blade, it looks easy. The instructions are good with step by step diagrams. When cutting “low thickness” pieces, it sings with speed an accuracy. “low thickness” = 1/4″ to 1.5″ (what I’ve done so far).The bad news:This may just be MY expectations but I wanted to slice 2×4 (actual 2×3.5) cedar (soft wood) into 1/4″ slices along the 3.5″ axis. To give you an example, the work piece was 2×3.5 in with a 6″ length. about 2″ in, it started to slow down. About 3″ in, it stopped. I don’t mean smoke and/or groans, no, I mean just slowed down and stopped. I could complete the job, but I would have to go comically slow (I timed 75 seconds to push through a 6″ length of cedar) AND would have to stop from time to time when the blade started to slow down. I looked to see if I could speed up the motor but i didn’t find anything so it may not be an option.Overall:As long as you don’t want to make box sides or cut 3″ wide softwood, this is great. It doesn’t make much noise and has a standard size dust extraction port, so if that’s what you’re looking for… stop looking. For anything else, I would spend the extra money and get something else.I’m not going to return it as it meets more than 50% of my needs, but, I wouldn’t buy it again.