WEN 5-1/8 in. Compound Cross Slide Industrial Strength Benchtop Vise

$105.12

Prepare yourself to conquer all your work projects at ease with the addition of this WEN Compound Cross Slide Industrial Strength Benchtop Vise.

In stock

Description

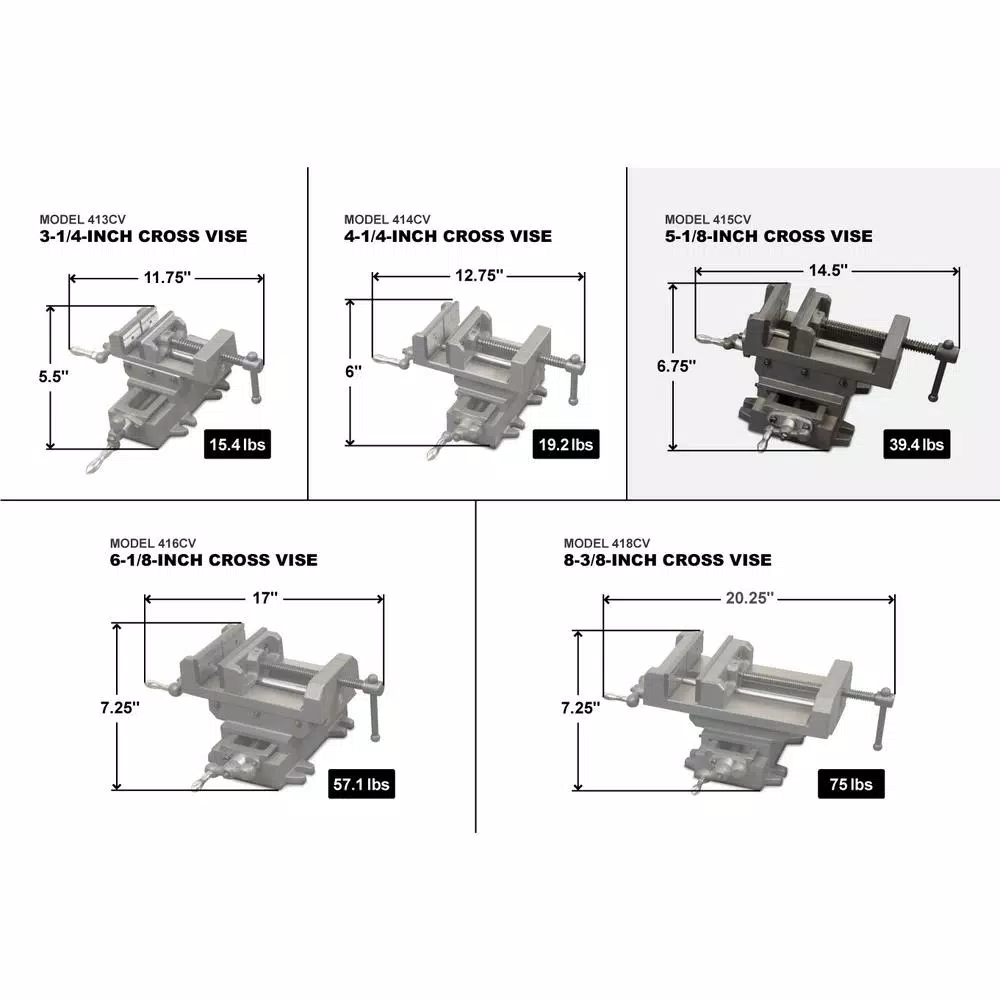

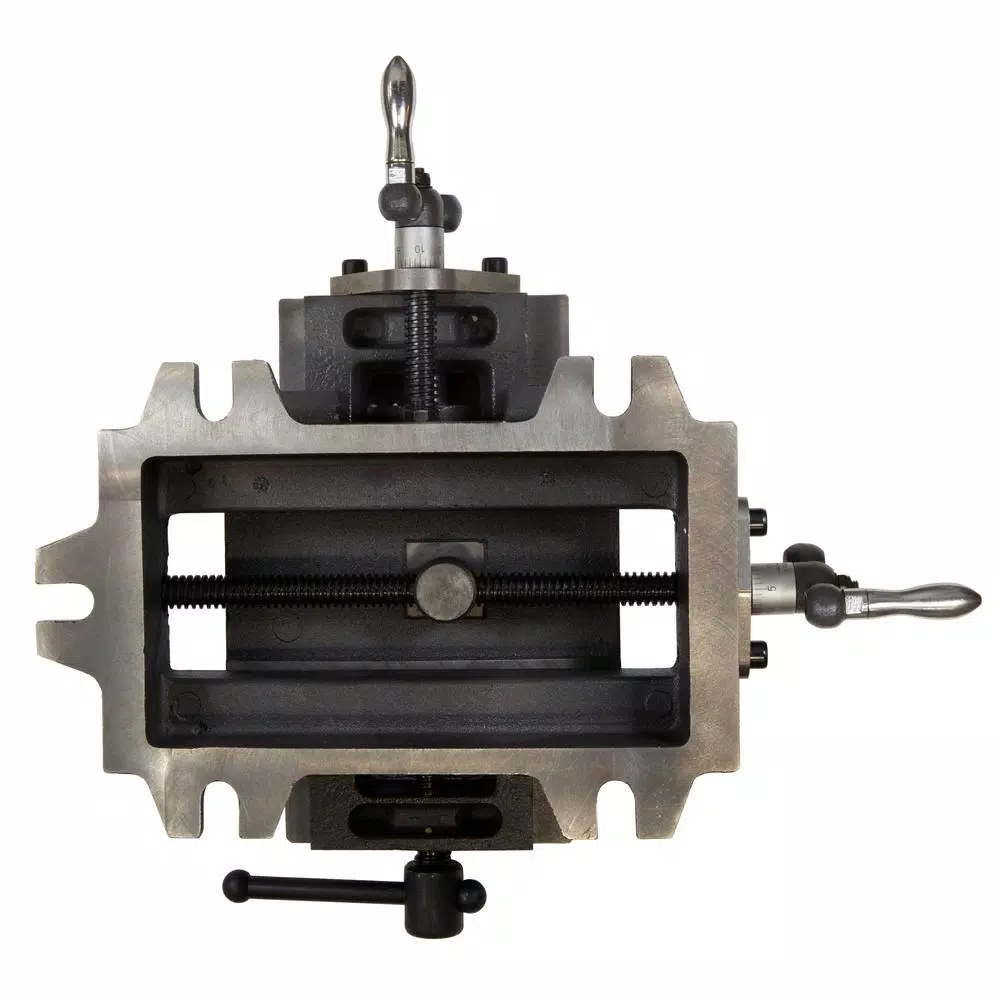

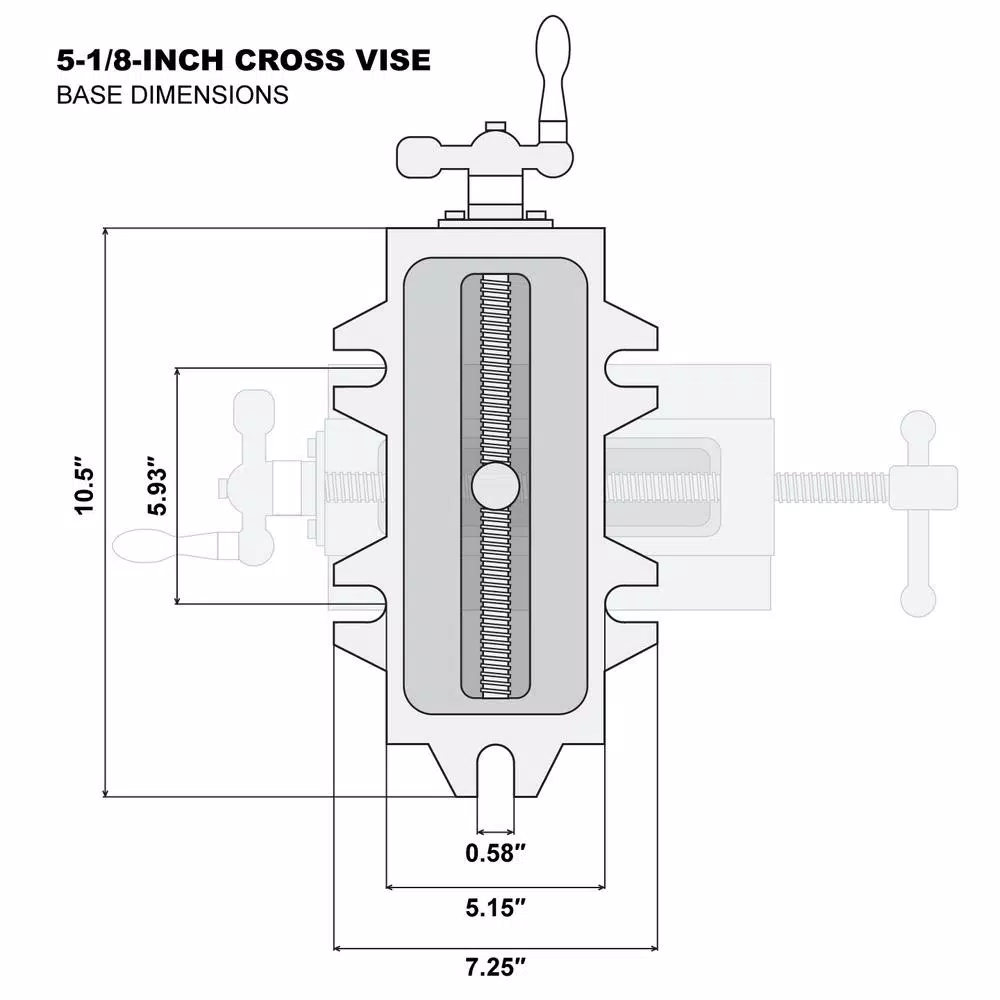

Remember when you could make fine-tune adjustments with the simple turn of a wheel. The WEN 5-1/8 in. Cross Vise provides stable support for your workpieces. Perfect for incremental drilling and other precision work. Made from heavy duty powder-coated cast iron, the WEN Cross Vise grips tightly onto your workpieces, providing over 1900 lbs. of clamping force. The 5 in. x 1.75 in. jaws open up to 5.125 in. wide. Make minor adjustments along either axis with the onboard hand wheels. Each hand wheel features machined 0.1 mm increments, each full turn representing 3 mm of travel. The vise moves a full 5 in. (129 mm) along the x-axis and 6.5 in. along the y-axis (165 mm), making it the perfect companion for woodworkers and metalworkers alike. The fixed jaw features a V-shaped groove to hold round objects either vertically or horizontally while the removable handles help users easily install the vise into tight spaces. With five 1/2 in. mounting brackets positioned around the outside edge of the vise’s base, the WEN Cross Vise is easy to install onto your favorite table or workbench. And because it’s a WEN product, your sliding vise comes backed by a two-year warranty, a nationwide network of skilled service technicians and a friendly customer help line all to make sure you remember WEN.

- 5 in. x 1.75 in. jaws open up to 5.125 in. wide

- Constructed of industrial-strength powder-coated cast iron

- Hand wheels feature machine-marked 0.1 mm increments for maximum precision

- Jaws travel 5 in. left and right and 6.5 in. front and back

- Five 1/2 in. mounting brackets allow for easy mounting to your workbench

- Heavy-duty build prevents walking and wobbling during operation

- Perfect for jobs requiring maximum accuracy and precision

Additional information

| Weight | 39.68 lbs |

|---|---|

| Dimensions | 15.15 × 14.37 × 6.97 in |

| Clamping Strength (lb.) | 1984 |

| Duty Rating | Heavy |

| Hand Tool Type | Vise |

| Individual/Set | Individual |

| Jaw Capacity | 5.25 in |

| Jaw Width | 1.25 in |

| Material | Cast Iron |

| Model | 415CV |

| Swivel base | No |

| Throat Depth | 5.25 in |

| Tools Product Type | Hand Tool |

Reviews (12)

12 reviews for WEN 5-1/8 in. Compound Cross Slide Industrial Strength Benchtop Vise

Only logged in customers who have purchased this product may leave a review.

Related products

Fastening Tools

Model# HT50PFastening Tools

Model# 28608Fastening Tools

Model# 225Fastening Tools

Model# JT27Fastening Tools

Model# MR33CFastening Tools

Wilton 6 in. Mechanics Vise with Swivel Base, 4-2/16 in. Throat Depth

Model# 21500Fastening Tools

Model# 906-ASFastening Tools

Model# DWS5026

Dayna Sporer (verified owner) –

It is doing everything I expected. Had to completely disassemble it and clean it then lightly smoothed out the travel surfaces, oiled and reassembled

Beverly Robel (verified owner) –

The WEN X-Y vise was an excellent solution for my needs. I mounted the vise to a custom adapter plate and installed it on a RYOBI 10″ bench drill press. I used this setup to “hog out” AR upper receivers in the “raw”, with a carbide milling bit. The results were fantastic…Just needed to lube with WD-40 and mill slow with small nibbles.

Luis Kutch (verified owner) –

I have a new work bench and needed a heavy duty vise with a compound cross slide, which this is. It was very easy to install so I see why there were no instructions on that. I do feel it should of came with directions on how to use the compound cross slide. The compound cross slide comes with a measuring tape on it which is a great feature. The benchtop vise and compound cross slide weighs approximately 40 lbs. which is pretty heavy. I use the vise part at least once a week. The compound cross slide was very hard to slide so I oiled up the screws and that took care of that problem. I am pleased with it and I feel every work bench should have some type of vise attached to it.

Kiana Pfeffer (verified owner) –

Works on my small drill press but just barely I was going to get the bigger vice glad I didn’t just enough room with the 5 1/8″ inch..The one thing I wish they would change is to mill a slot across the movable jaw like on the fixed side would be great for drilling brackets from flat stock.I feel it is a great value for the price and quality. Add grease to the slides before using to help free up the movement.

Lionel Shields (verified owner) –

Works perfect mounted to my WEN 10” drill press

Reid D’Amore (verified owner) –

It was packaged with the gibs tightened so it would not move in shipping. I disassembled the whole thing and filed and sanded the gibs and reassembled the unit so it works ok. It did the trick for me. I needed to make some parts out of G10 and was able to mill them with this thing clamped to my drill press.

Billy Koss (verified owner) –

I have a new work bench and needed a heavy duty vise with a compound cross slide, which this is. It was very easy to install so I see why there were no instructions on that. I do feel it should of came with directions on how to use the compound cross slide. The compound cross slide comes with a measuring tape on it which is a great feature. The benchtop vise and compound cross slide weighs approximately 40 lbs. which is pretty heavy. I use the vise part at least once a week. The compound cross slide was very hard to slide so I oiled up the screws and that took care of that problem. I am pleased with it and I feel every work bench should have some type of vise attached to it.

Bradley Reichel (verified owner) –

I bought this to mill out an 80% lower using my drill press. The packaging was not adequate to protect this thing and the end of one of the threaded rods got pretty messed up. I was able to get the handles on with the use of a file and a lot of force. Out of the box it was unusable, but with a lot of lithium grease and some adjustments of the bolts on the sides, I was able to get it to work well enough for my needs. The threaded rods were all warped a little, but the threaded rod on the main clamp was extremely warped, but luckily this isn’t something I need to turn constantly and I was able to tighten it enough to use. One of the biggest problems with this thing is the mangled ends of the rods that were damaged in shipping stick out next to the handles you turn to move the vice around. Because of this I ended up with numerous small cuts and scratches on my fingers. Overall it worked well for my needs, but whether or not I would recommend this product really depends on what you need to do.

Geovanni Collins (verified owner) –

Works great out of the box..

Gina Howell (verified owner) –

This vise is extremely heavy duty. It weighs almost 40 pounds and is very well built. The cross vise apparatus is a bit sticky at first. It may need to be oiled to help the screws turn easier. I was a bit disappointed it wasn’t shipped with any instructions. The handles were relatively easy to install, but at first it wasn’t clear where or how exactly they should be installed. The handles are equipped with a measurement tool so you can easily control exactly how much adjustment is made in the vice location.Great vise.

Florine Windler (verified owner) –

When looking for a drill press vise don’t pass by this unit! It has the weight to be very stable, the fine adjustments for accuracy, and adjustments to keep the moving parts as snug and smooth operating as the first time it is used. The only feature that could make this vise any better would be a rapid release for the jaws, but at this price point you won’t find a better built vise.

Austin Marks (verified owner) –

I have been using a stationary drill press vice for a while, so when this vice ended up on my press, it literally changed the whole game for me. I used to have to move my old vice around on the press platform and then adjust the platform in an attempt to align the piece to my drill bit. No more of that nonsense. This vice adjusts 5 inches left-to-right and 6.5 inches front to rear, so there is plenty of adjustment to align your work piece under your bit. This vice weighs about 41 lbs, and has five mounting brackets, so once properly mounted, it isn’t moving. A HUGE oversight by manufacturer is its failure to include instructions! The vice has two handles that are pretty simple to install, but some folks may need help in doing that, so instructions would help out these folks. The real problem I ran into was this: I received my first vice with no instructions and the bottom slider was so tight, I could not turn it by hand (I cleaned and re-oiled it, etc). The company took it back and gave me a replacement with no hassle. The second vice was worse in that both sliders were tight and very difficult to move. I telephoned WEN and spoke to a representative who was very helpful. He instructed me to loosen the six side adjustment set screws (three on each slide). That did the trick! Again, for some folks who are knowledgeable with tools like this, they might have known to do this, but I was not familiar with the internal workings of this tool, WHICH IS WHAT INSTRUCTIONS ARE FOR! I suspect that the first vice was fine and could have been adjusted to work properly if there had been instructions. Since both of my vices came with very tight adjustments, I suspect WEN ships them all that way, so buyers really need to be instructed on how to properly adjust the slides. If you back off too much on the 3 set screws, the slide will wobble and not hold your piece securely…too tight and the slide will drag and be hard to adjust with your hand. It takes patience and trial and error, but once the screws on my second vice were properly set and locked, neither slide wobbled and the slides moved easily using the handle. I am a DIY’er and not a professional contractor, so I can’t attest to this tool’s durability over extended periods of constant use, but it is a heavy and sturdy tool, and I know it’ll work well for me for a long time, and I suspect it’ll do the same for professionals too.