WEN 14 in. 66-Tooth Carbide-Tipped Professional Metal Saw Blade for Mild Steel Cutting

$53.19

Cut through metal pipes, rods, steel studs and sheet metal with the help of WEN 66-Tooth Carbide-Tipped Professional Metal Saw Blade for Mild Steel Cutting.

In stock

Description

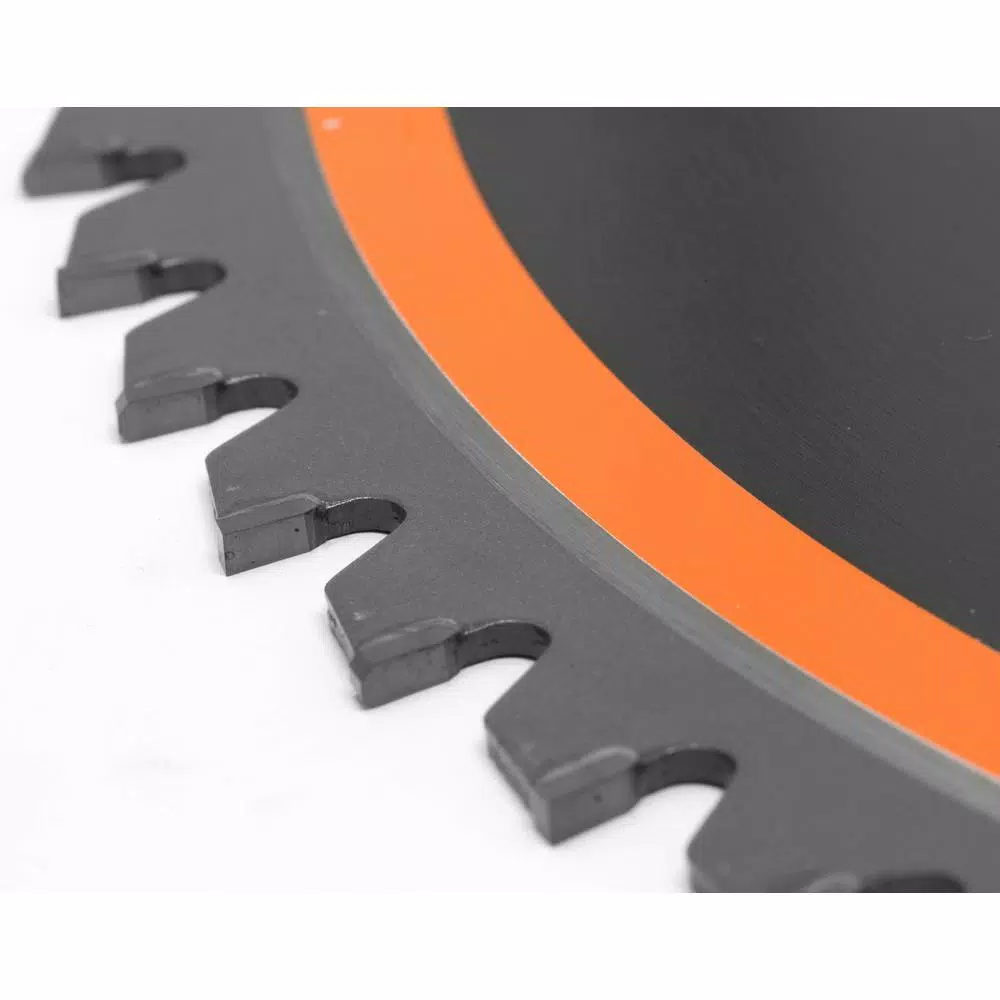

Remember when you had a smooth and powerful cut? The WEN 14-Inch Metal Saw Blade provides reliable and accurate performance, maintaining its straight shape and sharp edges for longer than the competition. The machine-cut carbide-tipped teeth slice through mild steel, making easy work out of pipes, square tubes, angle iron, and other ferrous metals. The 1-inch arbor allows for compatibility with 14-inch dry-cut metal saws, chop saws and circular saws. Our unique dry-cut-capable design limits the heat and burrs created by the competition. This lightweight, ultra-thin blade provides maximum efficiency during operation, leaving behind a kerf of a mere 1/10 of an inch wide (2.4 mm). It’s time to get reliable and powerful performance with a WEN Saw Blade. Remember when you had a blade that lasted? Remember WEN.

- Featuring a 14-inch diameter (355 mm), a 1-inch arbor (25.4 mm), and a rating of up to 1450 RPM

- Perfect for dry-cutting through steel and ferrous metals up to 1 inch in thickness

- Ultra-thin 1/10-inch kerf (2.4 mm) provides clean and efficient cuts

- Designed with 66 carbide-tipped teeth for general-purpose mild steel cutting

- Compatible with 14-inch dry-cut metal saws, chop saws and circular saws

Additional information

| Weight | 3 lbs |

|---|---|

| Dimensions | 16.34 × 14.17 × 0.67 in |

| Arbor Size | 1 |

| Color Family | Silver |

| Material Cut | Metal |

| Model | BL1466 |

| Number in Package | 1 |

| Number of Teeth | 66 |

| Power Tool Accessory Type | Circular Saw Blade |

| Saw Blade Diameter (in) | 14 |

| Saw Blade Material | Steel |

| Tools Product Type | Power Tool |

Reviews (8)

8 reviews for WEN 14 in. 66-Tooth Carbide-Tipped Professional Metal Saw Blade for Mild Steel Cutting

Only logged in customers who have purchased this product may leave a review.

Related products

Saw Blades

Milwaukee 6 in. 14 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5182Saw Blades

DEWALT 8 in. 18 Teeth per in. Demolition Reciprocating Saw Blade (5-Pack)

Model# DW4821Saw Blades

Milwaukee 44-7/8 in. 18 TPI Bi-Metal Deep Cut Portable Band Saw Blade

Model# 48-39-0520Saw Blades

Model# D1060XSaw Blades

Milwaukee 12 in. 18 Teeth per in. Medium Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5189Saw Blades

Milwaukee 6 in. 24 Teeth per in. Thin Metal Cutting SAWZALL Reciprocating Saw Blades (5 Pack)

Model# 48-00-5186Saw Blades

Milwaukee 44-7/8 in. 10/14 TPI Bi-Metal Deep Cut Portable Band Saw Blade

Model# 48-39-0550Saw Blades

Model# D1080X

Otha Purdy (verified owner) –

Works great as good as the more expensive ones.

Dulce Hagenes (verified owner) –

Great metal blade. Well balanced, good size and weight. Fits perfectly over the one inch arbor-no slop or play. When in use, the blade resists vibration and cuts well. I did not exceed 1/2 inch thick steel rebar and it cut through it effortlessly. The heat was not excessive and the teeth all stayed in near perfect condition after 20 or so cuts. A blade far more durable than an abrasive blade that will last substantially longer

Vincent Cronin (verified owner) –

14 in. 66-Tooth Carbide-Tipped Professional Metal Saw Blade for Mild Steel Cutting was received in a short amount on time after ordering, The blade had good weight to it with 66 Carbide tipped teeth attached to the blade. The blade is a thin kerf blade making thin cuts possible in the metal. The blade comes with a 1″ arbor fitting most 14″ crop saws. When cutting 1/2″ rebar the blade delivered a smooth cut with little effort. A good metal cutting blade at a reasonable price.

Natalie Schmeler (verified owner) –

I used to do all my cutting with an abrasive cut-off disc. It’s pretty much just the way my dad did it so I followed suit without questioning. Then I discovered a portable electric band saw and now these cut-off blades. You don’t need water for these, yet you have much less sparking and no wheel residue piling up on your workbench (messy gritty yucky). Make sure and check the RPMs on your cutoff saw, you don’t want to overspin these. It’s hard for me to think that metal-on-metal could ever work for any length of time, but for light/thin gauge material, this blade proved me wrong! Spendy, but a good tool and a good investment; I’ve heard they can even be resharpened.

Mittie Moore (verified owner) –

I’ve always used Diablo blades in my Ironton dry cut saw but for the cost savings I was willing to try the WEN blade. The blade cut smooth and true. As with all metal cutting operations slow and steady is the rule. Slow feed at the end of the cut leaves less sharp burrs you will need to clean up. The WEN blade preformed well, didn’t get to hot and with care it should last, hopefully outlast the more expensive Diablo’s.

Emma Christiansen (verified owner) –

good

Chase Cronin (verified owner) –

Best priced cold saw blade for metals and it cuts just as good as the $100 Evolution blade that came on my saw !

Icie Murray (verified owner) –

I always cut my metal with an abrasive blade, It was messy and there was always the chance of starting a fire. But not any more. I don’t know why I didn’t do it sooner. This blade is good for cutting most mild steel, plastic and aluminum. It is made to last and can be sharpened many times. This is a low speed blade with a maximum speed of 1450 RPM. So you need to make shore that your saw will not over speed the blade. I don’t know if you have seen a blade explode, but I have and you don’t want to be around. I hope this help with your decision and good luck with your project.