XYZprinting da Vinci 1.0 Pro 3D Printer

$324.97

In stock

Description

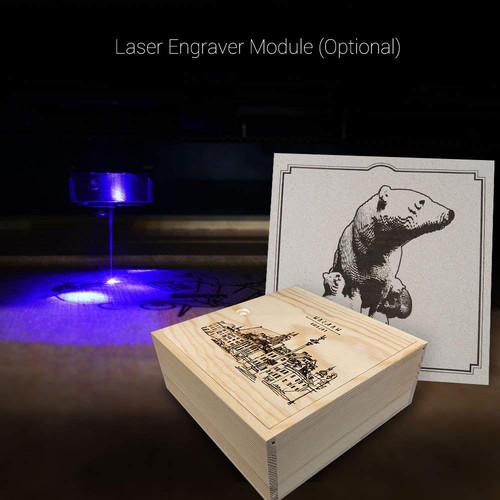

The da Vinci 1.0 Pro 3D Printer from XYZprinting allows you to adjust the temperature settings for the extruder nozzle and aluminum print bed, which makes it compatible with third-party 1.75mm filaments. Select your favorite filament brand for an optimal 3D printing experience. The da Vinci Pro also has an auto-loading filament system that will ensure the filament is loaded correctly and ready for use.

Additional information

| Weight | 57.8 lbs |

|---|---|

| Dimensions | 27 × 23 × 21 in |

| Print Technology | Fused Filament Fabrication (FFF) |

| 3D Scanner | No |

| Dimensions (W x H x D) | 18.4 x 20 x 22" / 46.74 x 50.8 x 55.88 cm |

| Storage Temperature | 50 to 104°F / 10 to 40°C |

| Operating Humidity | 30 to 60% |

| Operating Temperature | 59 to 89°F / 15 to 32°C |

| AC Input Power | 100 to 240 VAC, 50 / 60 Hz |

| Supported 3D File Types | .3w, .gcode, .obj, .stl |

| Supported Operating Systems | Android (Version Unspecified)<br />Linux (Version Unspecified)<br />Windows 7 or Later<br />macOS X 10.1 or Later |

| Wi-Fi | Wi-Fi 4 (802.11n) |

| Wired Connections | 1 x USB Type-B (USB 2.0) |

| Monitoring Camera | No |

| Filament Spool Storage | Internal |

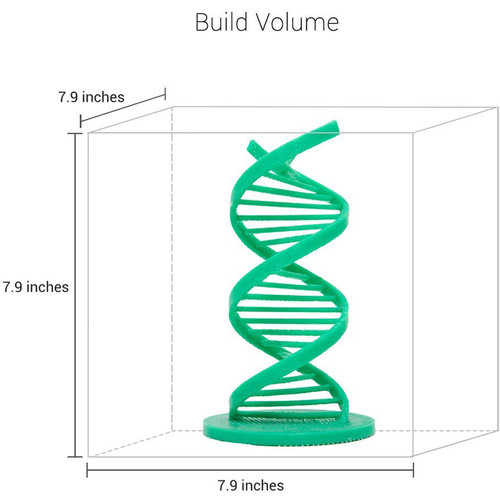

| Build Volume | 7.8 x 7.8 x 7.8" / 19.8 x 19.81 x 19.8 cm (1 Extruder) |

| Build Plate Composition | Aluminum |

| Build Plate Temperature | 105 to 194°F / 40 to 90°C |

| Build Plate Features | Auto Leveling, Heated |

| Build Area Type | Enclosed |

| Filament Compatibility | 1.75 mm Diameter: <br>ABS, HIPS, PETG, PLA, Wood |

| Print Speed | 120 mm/s |

| Positioning Precision | XY Axis: 12.5 micron / 0.0125 mm<br />Z Axis: 0.4 micron / 0.0004 mm |

| Extruder Nozzle Temperature | 338 to 464°F / 170 to 240°C |

| Supported Extruder Nozzle Diameter | 400 micron / 0.4 mm (Included) |

| Layer Resolution | XY Axis: 20 to 400 micron / 0.02 to 0.4 mm (5 Settings) |

| Number of Extruders | 1 |

| Warranty Length | Limited 1-Year Warranty |

Reviews (8)

8 reviews for XYZprinting da Vinci 1.0 Pro 3D Printer

Only logged in customers who have purchased this product may leave a review.

Related products

3D Printers & Accessories

FlashForge 1.75mm Flexible Filament for the Dreamer, Inventor Series, and Finder (0.5kg, Natural)

3D Printers & Accessories

3Doodler PLA Single Color Plastic Pack (Foggy Day Grey, 25 Strands)

3D Printers & Accessories

3D Printers & Accessories

NinjaTek Armadillo 1.75mm 75D TPU Nylon Alternative Filament (1kg, Grass)

3D Printers & Accessories

3D Printers & Accessories

NinjaTek Armadillo 1.75mm 75D TPU Nylon Alternative Filament (1kg, Fire)

3D Printers & Accessories

Chroma Strand Labs 3mm INOVA-1800 Filament (1 kg, LulzBot Green)

3D Printers & Accessories

Raymond Bashirian (verified owner) –

The item came very quickly. One of the sensor was displaced but aoon I found a way to resolve it. It is an excellent printer.

Hollie Zboncak (verified owner) –

Great machine for the money. Having owned commercial engraving machines costing thousands, I was a little skeptical at first. I have owned my 1.0 pro for 8 months and have printed and sold about 10kg of items with it. My designs are pretty simple and the supplied software works well for them. I was able to come up the learning curve pretty fast. I was able to figure out typical print problems like clearing clogs and poor bed adhesion on my own. I plan to buy another to increase my capacity.

Madonna Crist (verified owner) –

Can’t review the 3 in 1 3D Printer. I received the wront printer T W I C E

Otho Bogan (verified owner) –

It’s very versatile, able to perform multiple functions and use 3rd party filaments. It does have some problems but most of them can be solved by installing after market parts and tweaking settings, which makes it great for people just starting out. They can print some things right away for fun and also learn how to make it better for better quality prints. Those skills will travel on if they get a high quality professionnal computer later.

Garnett Bayer (verified owner) –

I made the mistake of purchasing a XYZ printer the printer broke just after 90 days XYZ would not replace the print head. Save your self money and aggravation, read up on this company they have many customer issues. There are many other brands with outstanding customer / warranty service, better products and reputation. lost customer

Torey Fay (verified owner) –

Lo desembale, conecte al pc y comence a imprimir sin problemas se me conecto fcilmente a red wi fi. la calidad de impresin , y opciones de parmetros que me da el programa, he quedado muy conforme con los resultados.

Carlos Rutherford (verified owner) –

Bought 3 of these printers. Have been running for less than 2 weeks. Only one remains functional. 1st one the feeder is running in reverse instead of forward. Have emailed and called tech support – no response. 2nd one, bracket broke and extruder jammed. Emailed and called asking if I could buy replacement parts. No response. 3rd one still working (for now). Overall, software is a weakness, instead of Cura – but decent build quality. Just wished they worked longer than a week. Is there any warranty? BHPhoto support for this?

Armand Ondricka (verified owner) –

Heres the long and short of it: I like the printer very much. I am pleased with the quality of the output. Heres what needs to be improved: 1) The calibration process is often repetitive and, thus, time-consuming. Sometimes between repetitions, the machine is giving me instructions that essentially undo the prior calibration step. Ive had as many as six or seven repetitions–30 to 40 minutes in total. ONE THING THAT WOULD HELP IS IF THE SYSTEM WOULD STAY AT TEMP BETWEEN CYCLES; MUCH OF THE TIME IS SPENT SIMPLY WAITING FOR THE NOZZLE AND BED TO COME UP TO TEMPERATURE EACH TIME. Below I suggest a work-around that can be used effectively in many cases. 2) The Active Menu display gives me the option to pause, resume, or cancel a print job. At a minimum, these features are necessary; however I would also like to see the ability to adjust speed. And z-axis fine-tuning would be nice. Calibration hack As a workaround for the laborious calibration, this has become my practice: I begin a print job making the assumption that the print platform is level. I let the machine begin to build the brim, looking for consistent adhesion and depth. If everything looks good, I leave it alone. Otherwise I carefully adjust the leveling while the machine prints–usually only one screw needs to be adjusted. Unless its way out of level, I can make this happen quickly and efficiently. Sometimes, I cant fix it. In this case, I abort the print and go through the calibration process. If youre new to 3D printing, heres what you look for: if the filament is exceptionally thin or the nozzle is pressing into the platform tape leaving an impression, then the platform is too high. On the other hand, if the filament is not adhering to the platform (as in, its not sticking around corners, but essentially following the nozzle in a straight line), then the platform is too low. To raise the platform, turn the screw in a counter-clockwise direction; to lower it, turn the screw in a clockwise direction. Be careful with this; if the platform is consistently high or low on all sides, then your problem may not be one of calibration but of z-axis adjustment.